Wind load testing device and method of vehicle-mounted mast lifting system

A lifting system and testing device technology, applied in measurement devices, electromagnetic measurement devices, testing of machine/structural components, etc., can solve problems such as large top offset, unsuitable for wind load testing of vehicle-mounted mast lifting systems, etc. Rapidly and continuously adjustable accuracy, reducing the effect of cylinder stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

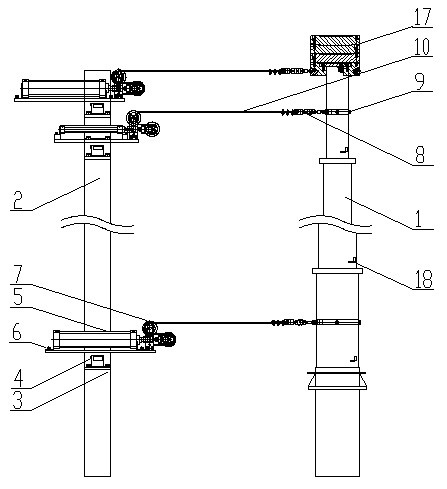

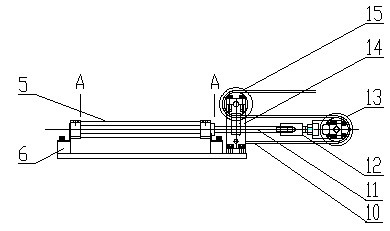

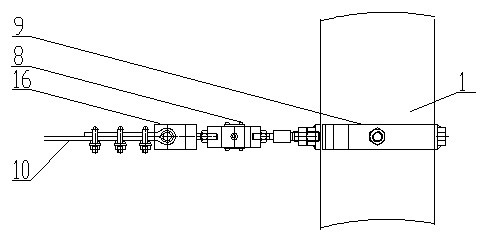

[0020] As shown in the figure, the wind load test device for the vehicle-mounted mast lifting system includes a multi-section telescopic vehicle-mounted mast 1, a reaction frame 2, a counterweight 17, a strain gauge 18, a tension device, and a computer; There are counterweights 17, strain gauges 18 are fixed at the bottom of each section of the multi-section telescopic vehicle-mounted mast 1, and the multi-section telescopic vehicle-mounted mast 1 is provided with a reaction force frame 2 parallel to the multi-section telescopic vehicle-mounted mast 1, and the reaction force frame 2 There are multiple tension devices on it, and the tension devices include reaction force frame beam 3, proportional pressure regulating valve 4, cylinder frame 6, pulley block 7, tension sensor 8, collar 9, steel wire rope 10, pull ring 16, air pipe 23, air source 24 , pulley block 7 comprises movable pulley support 12, movable pulley 13, fixed pulley support 14, fixed pulley 15; Reaction frame beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com