Method for measuring carbonic acid content in Sevelamer carbonate

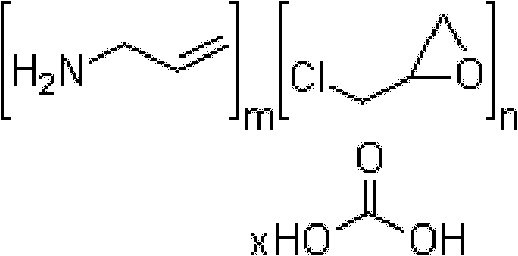

A technique for the determination of sevelamer carbonate and its method, which is applied in the field of determination of carbonic acid content in sevelamer carbonate, achieving the effects of strong specificity, strong operability, and clear principle of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

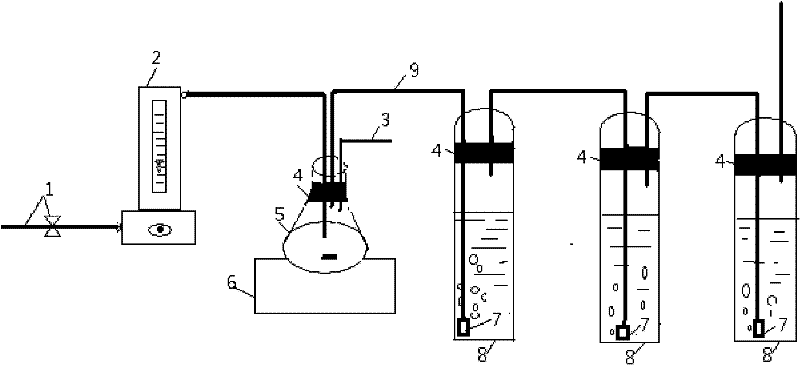

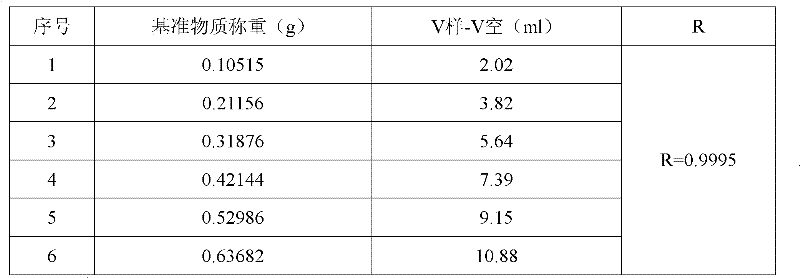

[0062] Precisely weigh about 1.0 g of the raw material of sevelamer carbonate (Nanjing Life Energy Technology Development Co., Ltd., batch number: 101001), put it in a 50 ml sample container 5, add 20 ml of water; add 50 ml of 0.1 mol / L NaOH solution (pH value 13 ) in three gas absorption pools 8; figure 1 In the test device shown, except for the carrier gas source and the vent and exhaust port of the flow control valve 1, the remaining ports are sealed; high-purity nitrogen gas is introduced, and the flow measuring instrument 2 is controlled so that the flow rate is 10-30ml / min. Turn on the heating and stirring device 6, and only in the stirring state, use a syringe to inject 6ml of 4mol / L hydrochloric acid solution into the sample container 5 through the liquid adding device 3, and after continuing to ventilate for about 30 minutes, combine the solutions in the gas absorption cell 8. According to potentiometric titration, titrate the combined absorption solution with 0.5mol / ...

Embodiment 2

[0066] Accurately weigh about 1.0 g of the raw material of sevelamer carbonate (Nanjing Life Energy Technology Development Co., Ltd., batch number: 101001), put it in a 50 ml sample container 5, add 20 ml of water; add 50 ml of 2 mol / L NaOH solution (pH value 14.3) In a gas absorption pool 8; adopt such as figure 1 In the test device shown, except for the carrier gas source and the vent port and exhaust port of the flow control valve 1, the other ports are sealed; high-purity argon gas is introduced, and the flow measuring instrument 2 is controlled to make the flow rate 70-100ml / min. Turn on the heating and stirring device 6, and only in the stirring state, use a syringe to inject 6ml6mol / L perchloric acid solution into the sample container 5 through the liquid adding device 3, and after continuing to ventilate for about 30 minutes, combine the solutions in the gas absorption cell 8. According to potentiometric titration, titrate the combined absorption solution with 0.5mol / L...

Embodiment 3

[0068] Accurately weigh about 1.0 g of the raw material of sevelamer carbonate (Nanjing Life Energy Technology Development Co., Ltd., batch number: 101001), and put it in a 50 ml sample container 5; add 100 ml of 0.05 mol / L KOH solution (pH value 12.7) to In a gas absorption cell; using such as figure 1 In the test device shown, except for the carrier gas source and the vent port and exhaust port of the flow control valve 1, the remaining ports are sealed; high-purity argon gas is introduced, and the flow measuring instrument 2 is controlled to make the flow rate 10-30ml / min. In the stirring state, use a syringe to inject 26ml of 1mol / L sulfuric acid solution into the sample container 5 through the liquid adding device 3, and after continuous ventilation for about 30 minutes, combine the absorption liquid. According to potentiometric titration, titrate the combined absorption solution with 0.5mol / L hydrochloric acid titration solution. Carry out a blank test at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com