Detection method and device of surface defect of mechanical part based on machine vision

A technology for mechanical parts and defect detection, applied in the direction of optical testing flaws/defects, etc., can solve the problems of incomplete degaussing, low efficiency, and high labor costs, and achieve the effect of omnidirectional scanning, high efficiency, and low labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The crankshaft is the main rotating part of the engine. After the connecting rod is installed, the up and down (reciprocating) motion of the connecting rod can be changed into a circular (rotating) motion. It is an important part of the engine. With the development of science and technology and the increasing demand for crankshafts, the processing efficiency of crankshafts has also been greatly improved in recent years; at the same time, as a power connector for various engines, the quality requirements for crankshafts are also becoming higher and higher. However, during the operation of mechanical equipment, the internal mechanical parts are subject to various stresses, and poorly processed mechanical parts are prone to abnormalities, resulting in system collapse and even catastrophic accidents. Therefore, the roughness detection of the crankshaft surface has become a very important checkpoint.

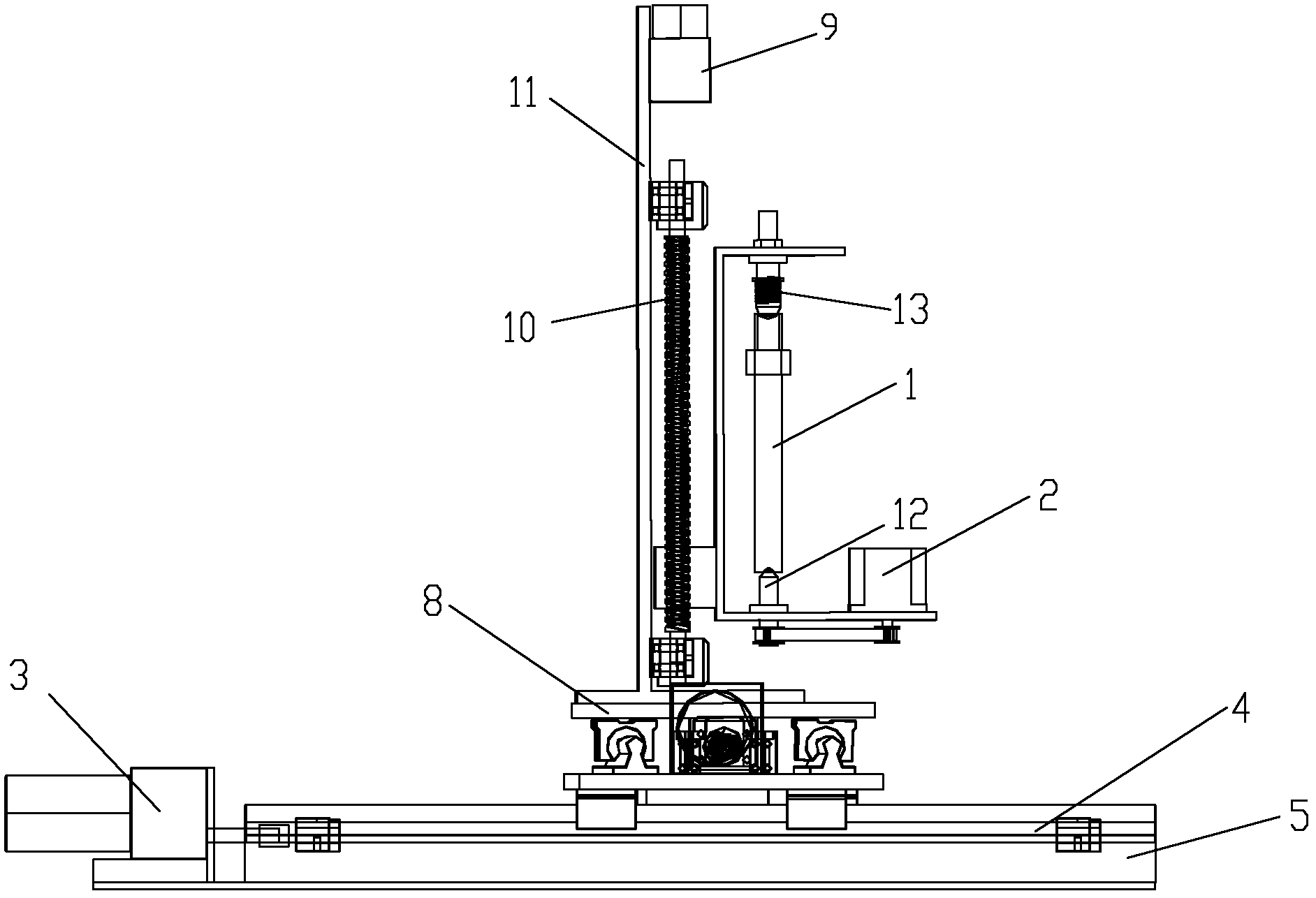

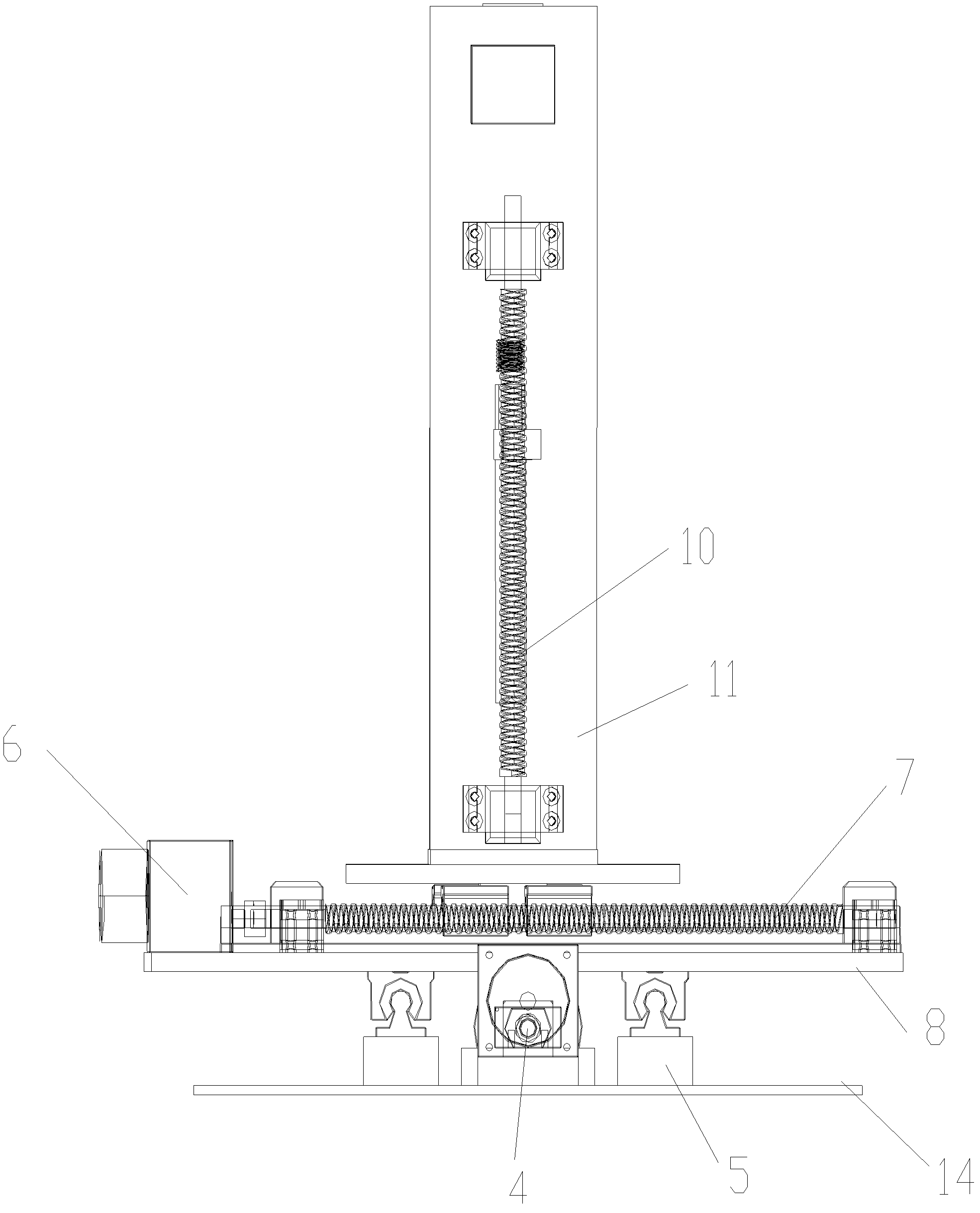

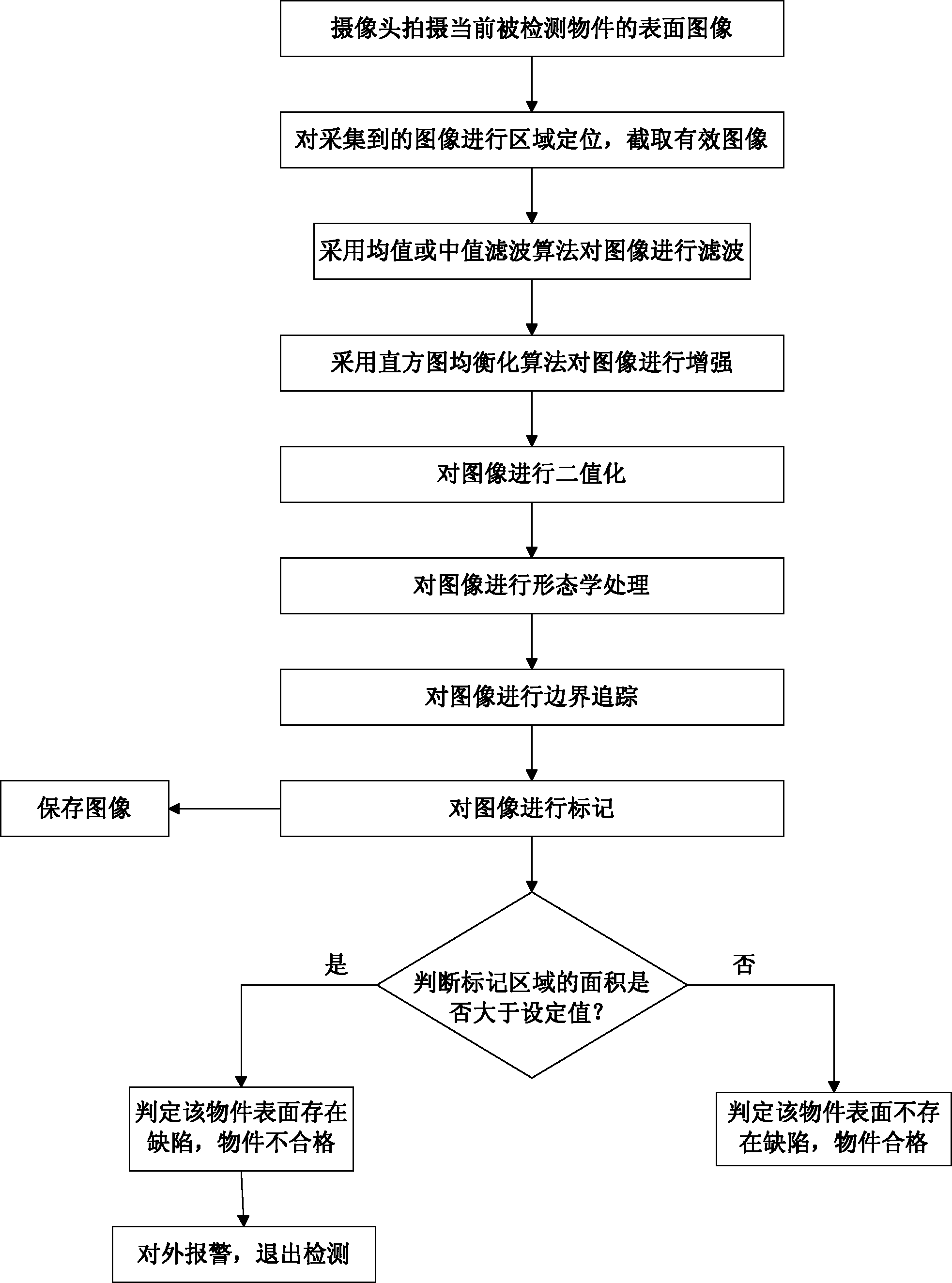

[0034] In this embodiment, the specific content of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com