Energy-saving control system of injection molding machine and operating mode of energy-saving control system

An energy-saving control system and technology for injection molding machines, which are applied in the field of energy-saving control systems of injection molding machines and their working modes, can solve the problems of reduced application area, insufficient flow, and inability to save energy, and achieve the effect of reducing oil output and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

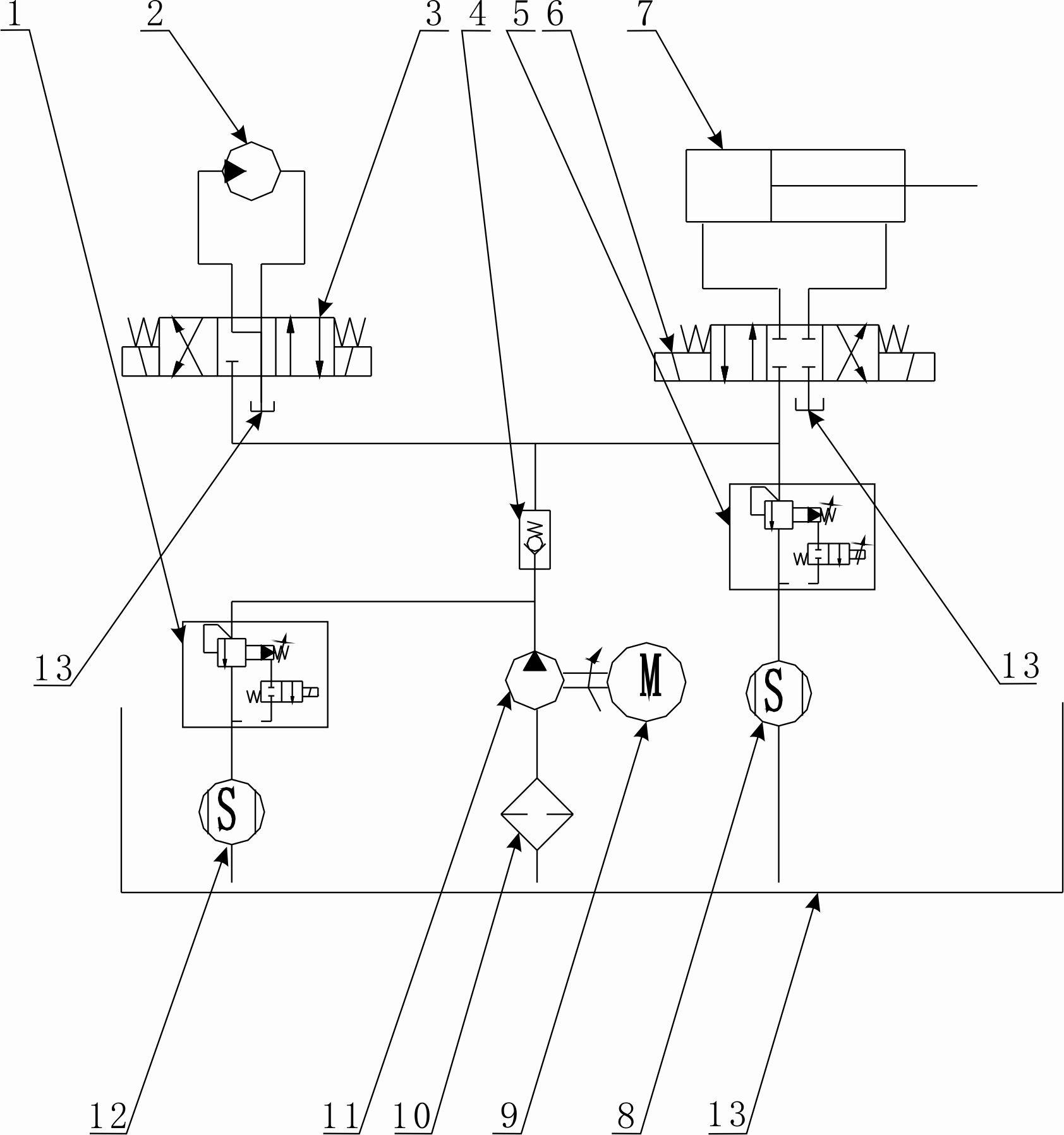

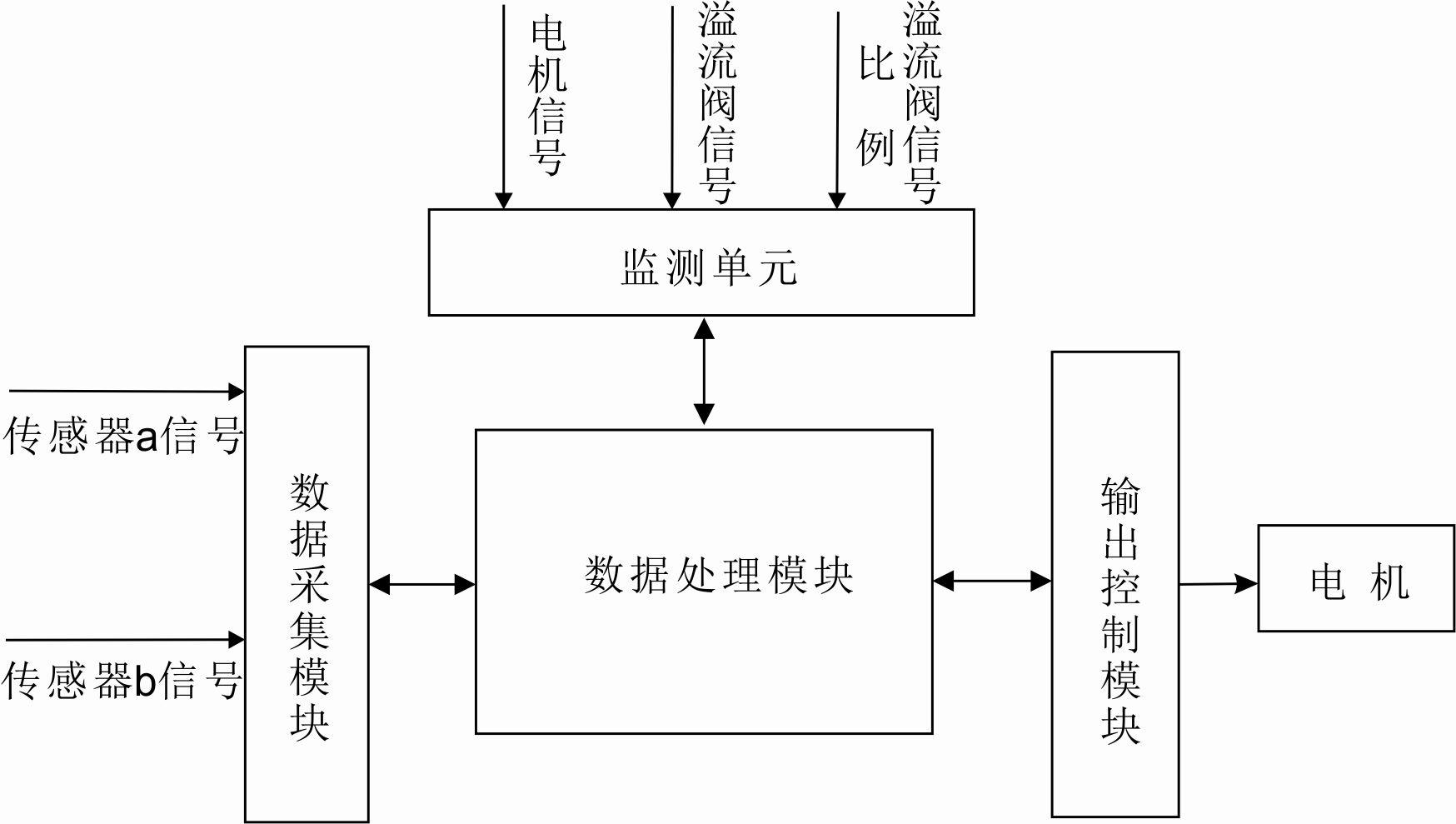

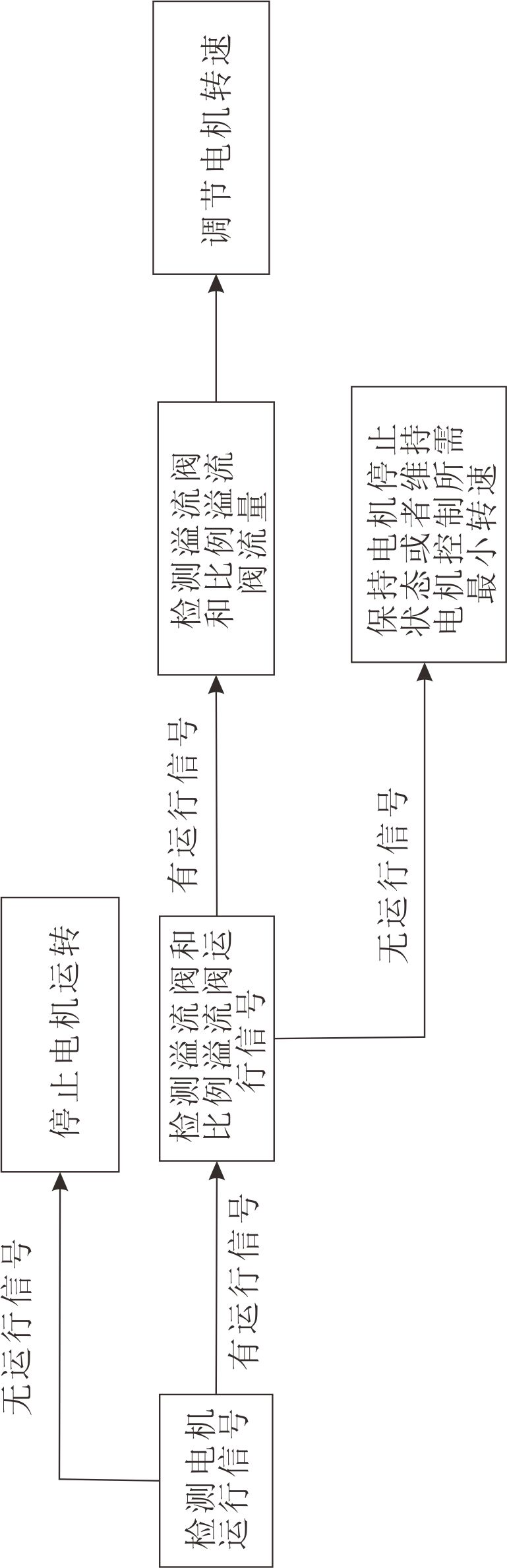

[0034] Embodiment: Taking an injection molding machine system equipped with a motor as an example, the structure and working mode of the energy saving control system of the injection molding machine are described. In terms of physical structure, the energy-saving control system of injection molding machine includes hydraulic part and electric control part. The electric control part can be used as a functional module of the injection molding machine system and integrated into the main control system of the injection molding machine. Such as figure 1 As shown, one motor 9 corresponds to a relief valve 1 and a sensor b12, so the sensor group includes a sensor a8 corresponding to the proportional relief valve and a sensor b12 corresponding to the relief valve.

[0035] Such as figure 1 As shown, in the hydraulic part, the motor 9 is connected to the oil pump 11; the inlet of the oil pump 11 is connected to the oil tank 13 through the oil pipe through the oil filter 10; the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com