Dynamic multistage anoxic / aerobic sewage treatment method

A sewage treatment method and technology for sewage treatment, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, low ammonia nitrogen removal efficiency, etc. The effect of effluent quality, enhancement of ammonia nitrogen removal capacity, and improvement of sewage treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0044] The dynamic multistage anoxic / aerobic sewage treatment method of the present invention comprises the following steps:

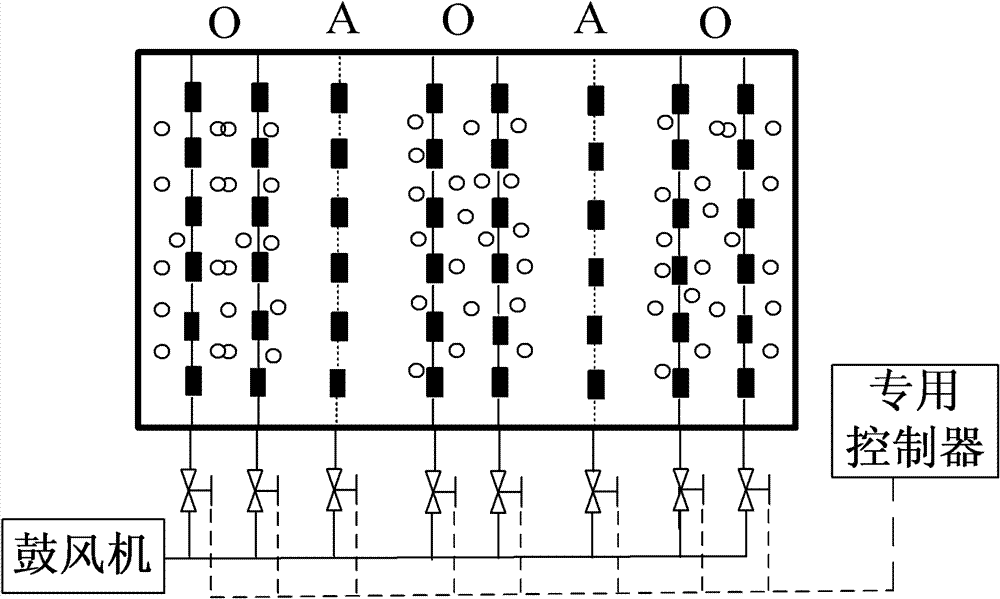

[0045] Install an aeration device at the bottom of the aeration tank of the sewage treatment plant;

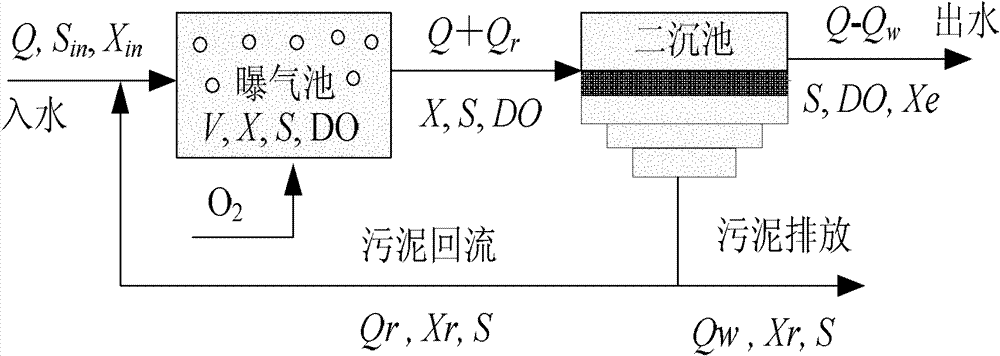

[0046] Establish a dynamic multi-stage anoxic / aerobic wastewater treatment process model;

[0047] On the basis of the above sewage treatment process model, determine the oxygen supply energy consumption performance function and constraint conditions of the dynamic multi-stage anoxic / aerobic sewage treatment process;

[0048] On the basis of the above-mentioned dynamic multi-stage anoxic / aerobic wastewater treatment process model and the performance function of oxygen supply energy consumption, two process parameters are dynamically determined through the optimization calculation method: one is the area distribution of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com