Solid nitrogen energy storage driving drug

A nitrogen storage, solid-state technology, applied in the field of fire-fighting energy storage driving agents, can solve the problems of easy aging of seals, leakage of stored gas, and inability to use, and achieve the effects of improving safety, improving fire-extinguishing efficiency, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

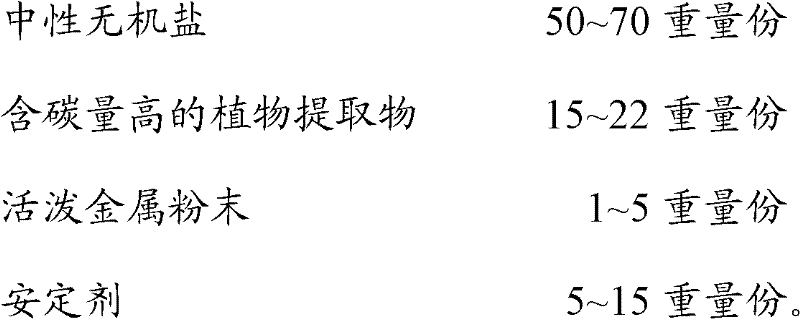

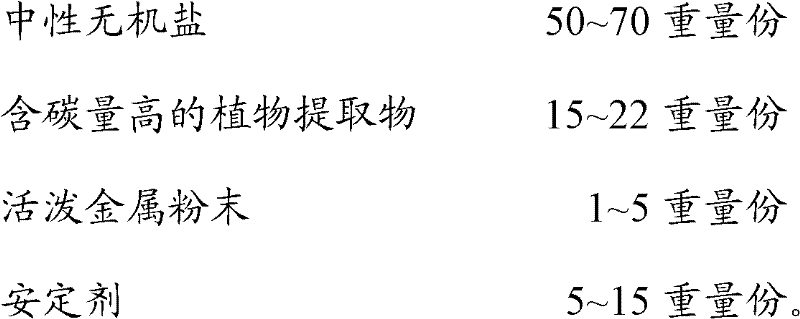

Method used

Image

Examples

Embodiment 1

[0023] (1) Take the material by the following parts by weight: potassium citrate, potassium permanganate and potassium nitrate are 70 parts by weight altogether, cane sugar and reed ash are 20 parts by weight altogether, aluminum powder 1 weight part, magnesium carbonate 5 parts by weight, resin 5 parts by weight of glue and 5 parts by weight of white wax.

[0024] (2) At normal temperature and in an environment where the relative humidity in the air is not greater than 80%, the above-mentioned materials are stirred evenly and fully mixed to obtain a mixture.

[0025] (3) Pass the above-mentioned mixture through a grading sieve with a mesh size of 80 or more and perform more than 3 screenings to obtain the solid-state nitrogen storage energy driving medicine.

[0026] (4) Put the electric heating wire and thermal wire of the excitation device in a metal container mould, put the above-mentioned solid nitrogen storage energy driving medicine into the metal container mould, and u...

Embodiment 2

[0029] (1) Take the material by the following parts by weight: potassium permanganate and potassium nitrate are 50 parts by weight altogether, charcoal, cane sugar and reed ash are 17 parts by weight altogether, aluminum powder and magnesium powder are 3 parts by weight altogether, magnesium carbonate and melamine are altogether 3 parts by weight. 15 parts by weight, 7 parts by weight of resin glue, 7 parts by weight of turpentine and white wax.

[0030] (2) At normal temperature and in an environment where the relative humidity in the air is not greater than 80%, the above-mentioned materials are stirred evenly and fully mixed to obtain a mixture.

[0031] (3) Pass the above-mentioned mixture through a grading sieve with a mesh size of 80 or more and perform more than 3 screenings to obtain the solid-state nitrogen storage energy driving medicine.

[0032] (4) Put the electric heating wire and thermal wire of the excitation device in a metal container mould, put the above-men...

Embodiment 3

[0035] (1) Take the material by weight as follows: 60 parts by weight of potassium citrate, 20 parts by weight of charcoal, 2 parts by weight of magnesium powder, 8 parts by weight of melamine, 8 parts by weight of resin glue and 8 parts by weight of rosin

[0036] (2) At normal temperature and in an environment where the relative humidity in the air is not greater than 80%, the above-mentioned materials are stirred evenly and fully mixed to obtain a mixture.

[0037] (3) Pass the above-mentioned mixture through a grading sieve with a mesh size of 80 or more and perform more than 3 screenings to obtain the solid-state nitrogen storage energy driving medicine.

[0038] (4) Put the electric heating wire and thermal wire of the excitation device in a metal container mould, put the above-mentioned solid nitrogen storage energy driving medicine into the metal container mould, and use a 100-200T hydraulic press to form the mould. Apply a pressure up to 1.8Mpa, and maintain it for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com