Sludge fuel and manufacturing method thereof

A sludge and fuel technology, which is applied in the field of waste treatment and resource utilization technology, can solve the problems of complex composition of papermaking sludge and bark, failure to provide a way of bark utilization, and large differences in physical form, and achieve sulfur The effect of low content, low cost and long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

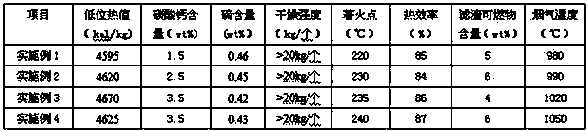

Examples

Embodiment 1

[0036] The raw materials of this embodiment include 20 parts by weight of sludge, 2 parts of sulfur-fixing agent (i.e. white mud), 0 parts of chlorine-fixing agent, 38 parts of bark and 36 parts of combustion aid (i.e. fuel coal). It includes 40% of municipal sludge and 60% of papermaking sludge by weight.

[0037] In step 2 of the present embodiment, the weight of water is 10% of the total weight of the muddy material, and the extrusion pressure of step 3 is 15 Mpa. In step 4, the cylinder is put into a vertical drying kiln and dried until the water content of the product is 4% (wt%), the drying temperature is 120°C.

Embodiment 2

[0039] The raw materials of this embodiment include 25 parts by weight of sludge, 3 parts of sulfur-fixing agent (i.e. white mud), 0 part of chlorine-fixing agent, 32 parts of bark and 36 parts of fuel coal. 50% municipal sludge and 50% paper sludge.

[0040] In step 2 of this embodiment, the weight of water is 16% of the total weight of the muddy material, and the extrusion pressure in step 3 is 20 Mpa. In step 4, the cylinder is put into a vertical drying kiln and dried until the water content of the product is 4% (wt%), the drying temperature is 130°C.

Embodiment 3

[0042] The raw materials of this embodiment include 30 parts by weight of sludge, 4 parts of sulfur-fixing agent white mud, 0 parts of chlorine-fixing agent, 25 parts of bark and 38 parts of fuel coal, and the sludge comprises 80% by weight. Municipal sludge and 20% paper sludge.

[0043] In step 2 of the present embodiment, the weight of water is 13% of the total weight of the muddy material, and the extrusion pressure in step 3 is 20 Mpa. In step 4, the cylinder is put into a vertical drying kiln and dried until the water content of the product is 1% (wt%), the drying temperature is 140°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com