Efficient and quick movable mould frame

A mobile formwork and fast technology, which is applied in the field of moving formwork, can solve the problems of box girder reinforcement and formwork assembly without parallel construction, mobile formwork cannot be maintained, and main girder and outer formwork are prone to displacement, etc. Achieve the effects of shortening the construction period, novel design and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

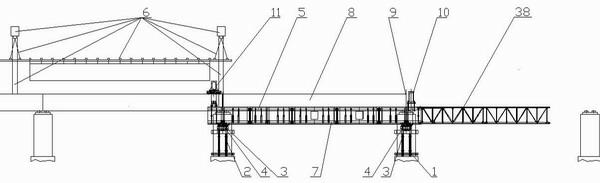

[0037] Attached below Figure 1~9 The present invention is described in detail:

[0038] Move the formwork efficiently and quickly, and follow the forward direction of the formwork construction, such as figure 1 As shown, it includes a front support system 1, a rear support system 2, a lateral movement system 3, a longitudinal through-hole running system 4, a formed main beam structure 5, a prefabricated steel bar hoisting mold system 6, a bottom mold and a bottom mold support system 7, Intima and intima support system 8, rapid maintenance system 9, front cross-arm system 10, rear cross-arm system 11.

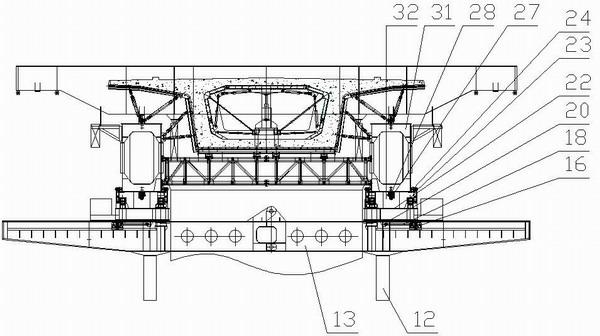

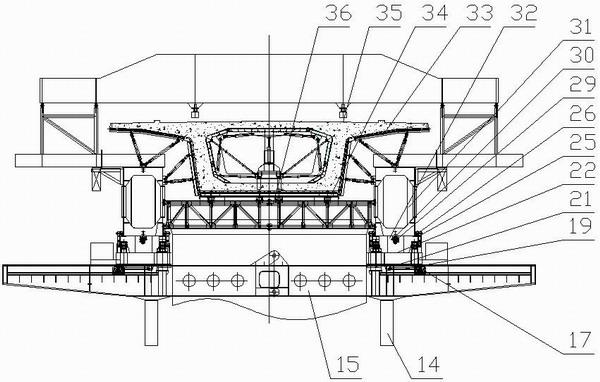

[0039] Front support system 1 such as figure 2 As shown, it comprises four front columns 12 and front joists 13, as figure 2As shown, the four pipe columns are installed on the bridge pier cap, the two front pipe columns 12 on the left and right sides are welded and connected by angle steel, and the front pipe columns 12 on the left and right sides are welded and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com