Rotary drilling rig and pulley yoke thereof

A technology of rotary drilling rig and pulley frame, which is applied in the direction of rotary drilling rig, rotary drilling, drill pipe, etc., which can solve the problems of mast interference, poor versatility, and inability to realize multi-functional drilling rigs, so as to avoid interference and increase The scope of application and the effect of increasing the lifting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

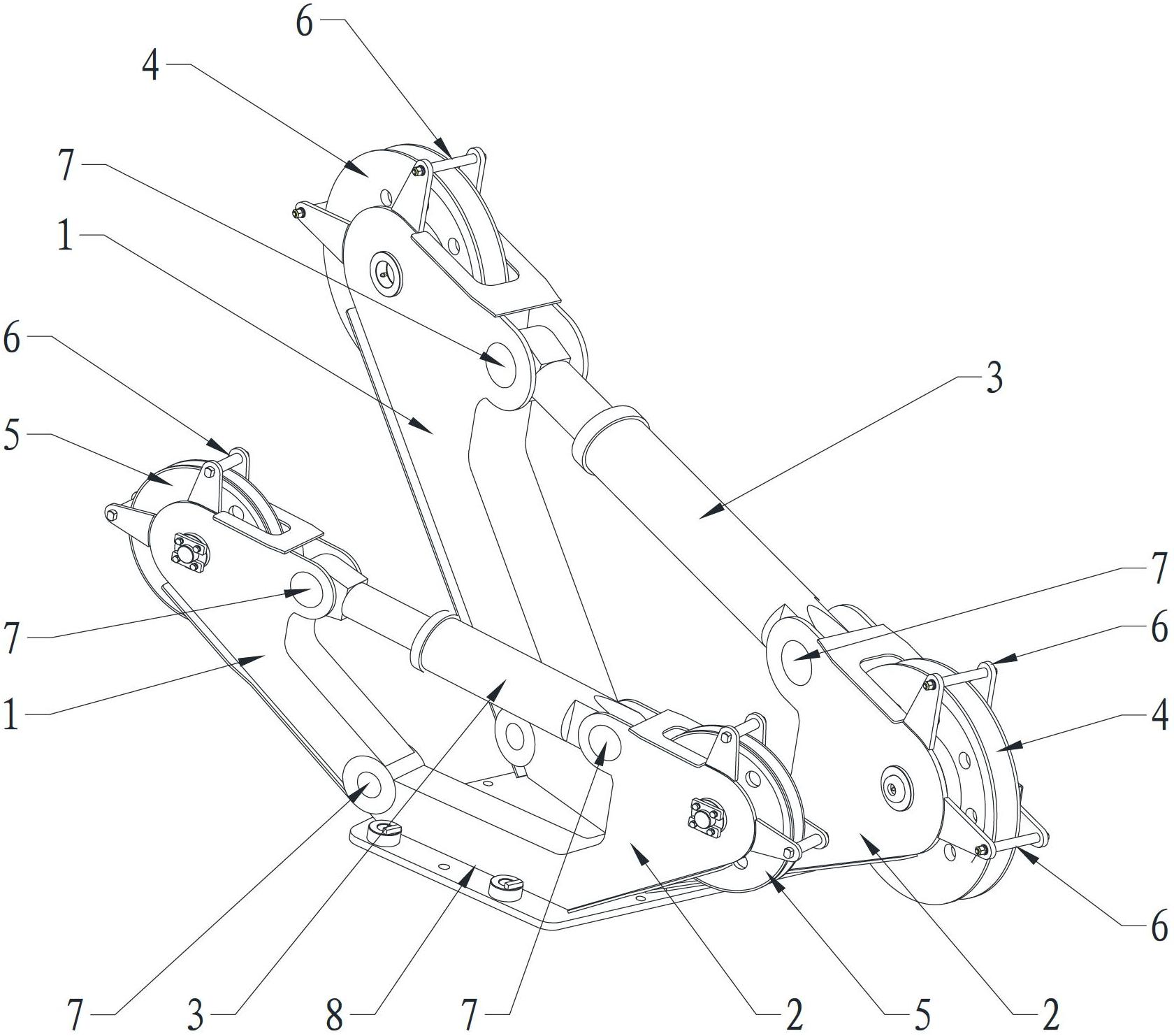

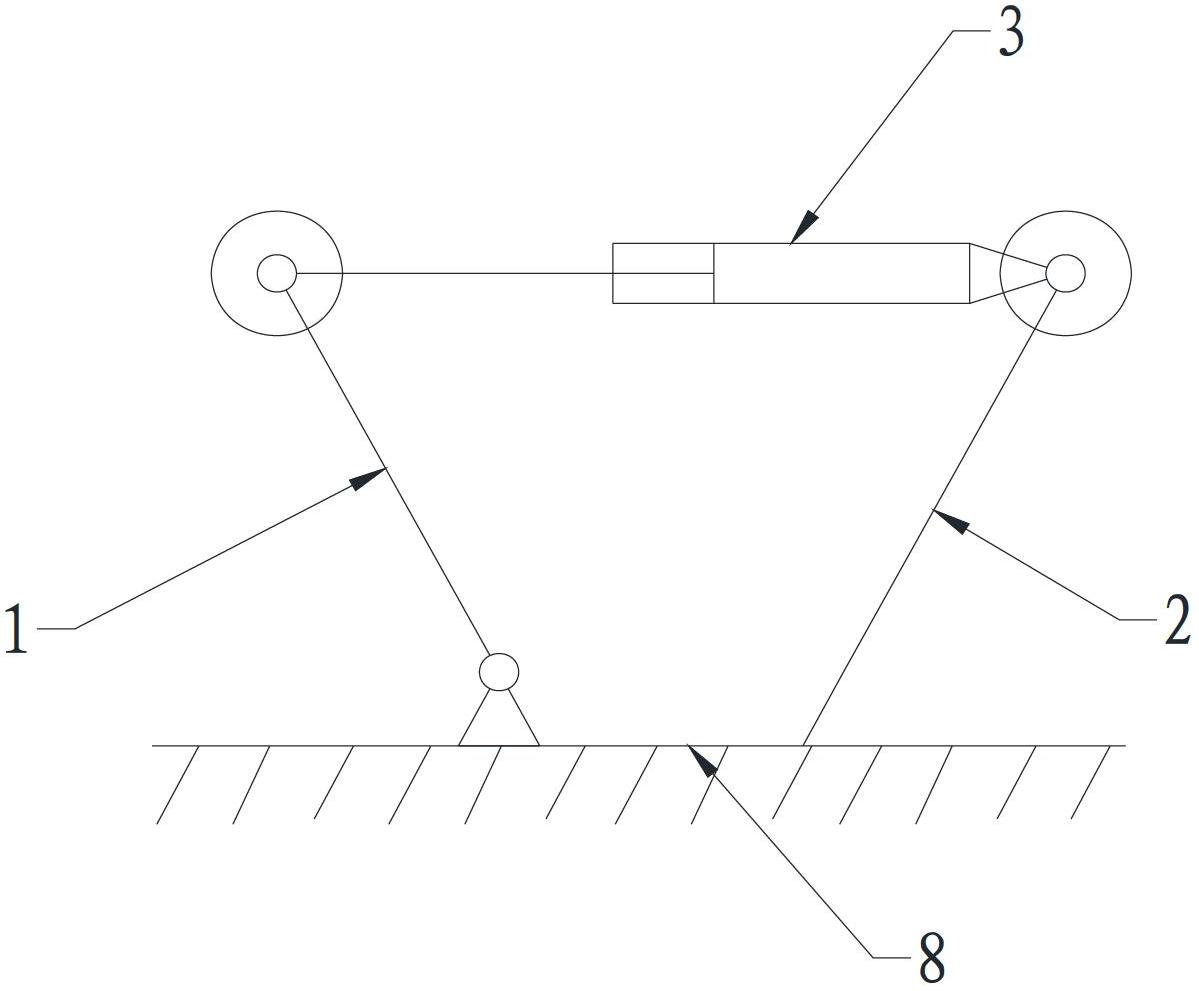

[0035] figure 1 and figure 2Is the relevant drawings of this embodiment, as shown in the figure, the device is a pulley frame for a rotary drilling rig, which includes a base 8 installed on the top of the mast of the rotary drilling rig and a first base mounted on the base 8 A pulley assembly and a second pulley assembly. In practical applications, generally speaking, the first pulley assembly is a large pulley assembly with a larger pulley diameter, and the second pulley assembly is a small pulley assembly with a smaller pulley diameter. The large pulley assembly Cooperate with the main hoisting wire rope, the small pulley assembly is matched with the auxiliary hoisting wire rope, and one side of the base 8 is rotatably connected with the top of the mast. In this embodiment, the rotatable connection mainly refers to but is not limited to the hinged form , the other three sides can be fixedly connected to the top of the mast with bolts, so that when the mast is down, the bol...

Embodiment 2

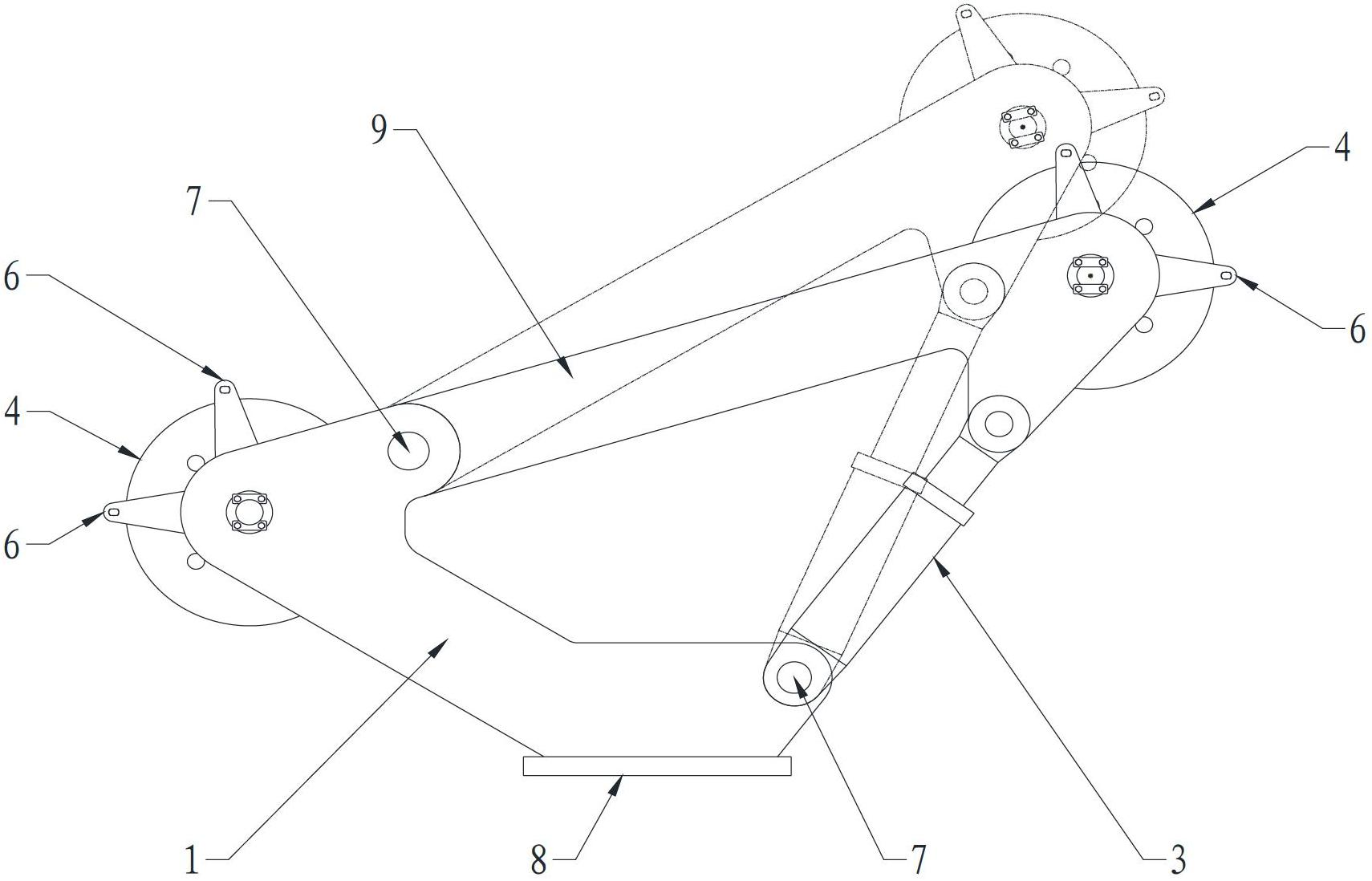

[0038] image 3 and Figure 4 It is the related drawings of this embodiment, as shown in the figure, compared with Embodiment 1, in this embodiment, the lower end of the forearm 1 is fixedly connected with the base 8, and the upper end is hinged with a non-stretchable cross arm 9, and the The rear arm is set as a telescopic hydraulic cylinder 3, the cylinder body of the hydraulic cylinder 3 is hinged to the base 8, and the piston rod is hinged to the other end of the cross arm 9. In addition, the structure and function of this embodiment are consistent with the first embodiment , so it will not be repeated here.

[0039] Similarly, as other modified implementations of this embodiment, the base may not be provided, and the large pulley assembly and the small pulley assembly may be directly connected to the top of the mast; only one of the two pulley assemblies may use a hydraulic cylinder to adjust the distance between the two pulleys. Distance, another pulley assembly that u...

Embodiment 3

[0041] Figure 5 That is the relevant drawings of this embodiment, as shown in the figure, compared with Embodiment 2, in this embodiment, both the forearm and the rear arm are set as hydraulic cylinder 3, and both ends of hydraulic cylinder 3 are also It is connected to the cross arm 9 and the base 8 in a hinged manner. Except for this, the structure and function of this embodiment are consistent with the second embodiment, so no more details are given.

[0042] Similarly, as other modified implementations of this embodiment, the base 8 may not be provided, and the large pulley assembly and the small pulley assembly may be directly connected to the top of the mast; only one of the two pulley assemblies may use the hydraulic cylinder 3 to adjust the two pulleys. The distance between, another pulley assembly that uses the existing non-adjustable pulley distance; the front arm and cross arm can be set as hydraulic cylinder 3, or the rear arm and cross arm can be set as hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com