Cavity forming apparatus for embedded chamber of underground engineering test model

A test model and underground engineering technology, applied in underground chambers, mining equipment, earthwork drilling, etc., can solve the problem of inability to bury the chamber into a cavity, and achieve a simple structure, easy extraction and molding, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

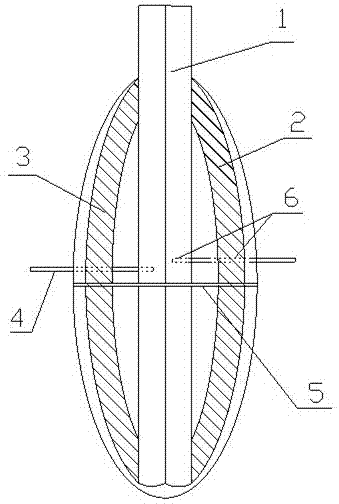

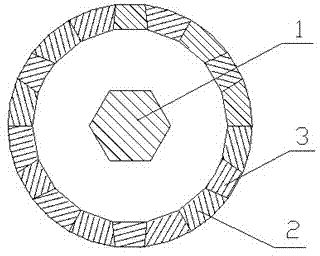

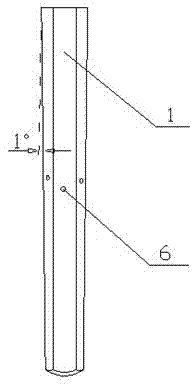

[0037] Such as Figure 1-9 As shown, the central mandrel 1 is provided with 18 positioning pin holes 6, and the central mandrel 1 forms an ellipsoid cavity structure with the surrounding A-shaped arcuate block 2 and B-shaped arcuate block 3, and the arcuate block includes There are 18 pieces in total of A-type arcuate block 2 and B-type arcuate block 3, which surround the center axis 1 in the order of ABA. Each arcuate block is provided with a positioning pin hole 6 and is fixed on the central mandrel 1 through a positioning pin rod 4 . A size-adjustable hoop 5 is arranged at the largest section in the middle of the outside of the ellipsoid cavity structure to tighten all the blocks.

[0038] The central axis 1 is in the form of an inverted hexagonal truncated pyramid, and its bottom surface is a partial ellipsoid, and the angle between each cone surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com