Light guide plate, manufacturing method thereof, and side-entry backlight module using the light guide plate

A manufacturing method and technology for a light guide plate, applied in the field of backlight modules, can solve the problems of bending, poor optical isolation effect, low yield, etc., and achieve the effect of high optical isolation effect, high optical isolation degree, and quantitative production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

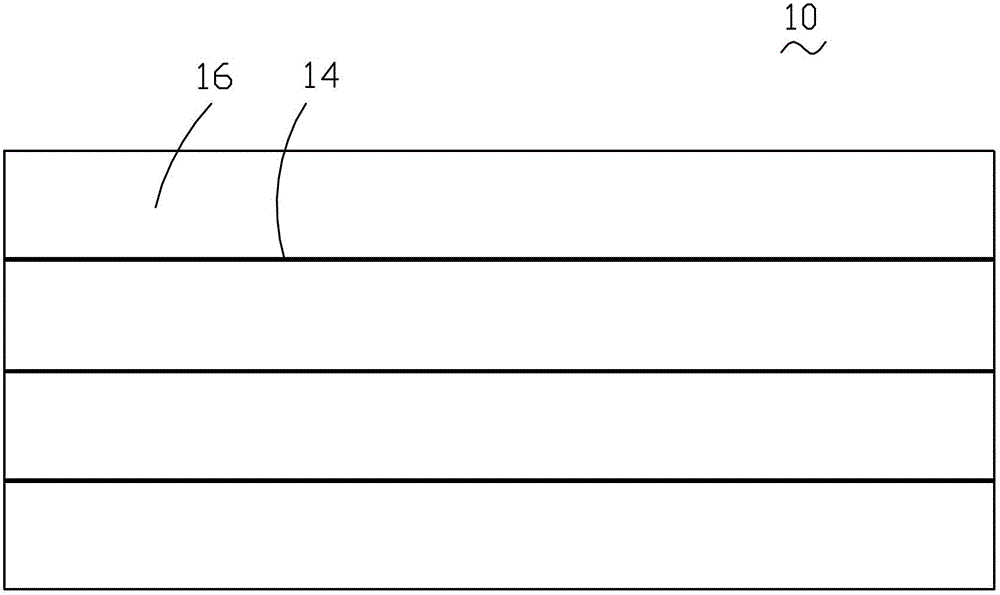

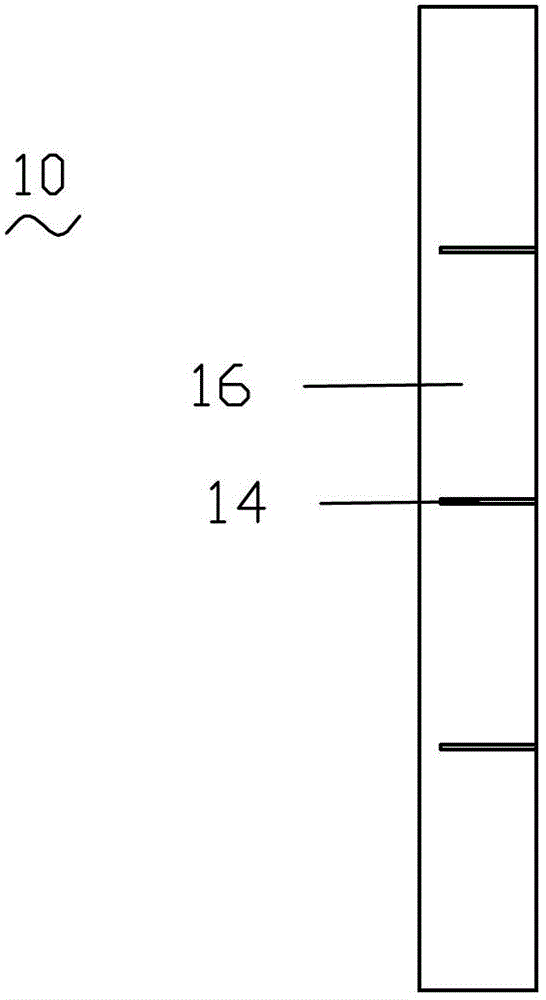

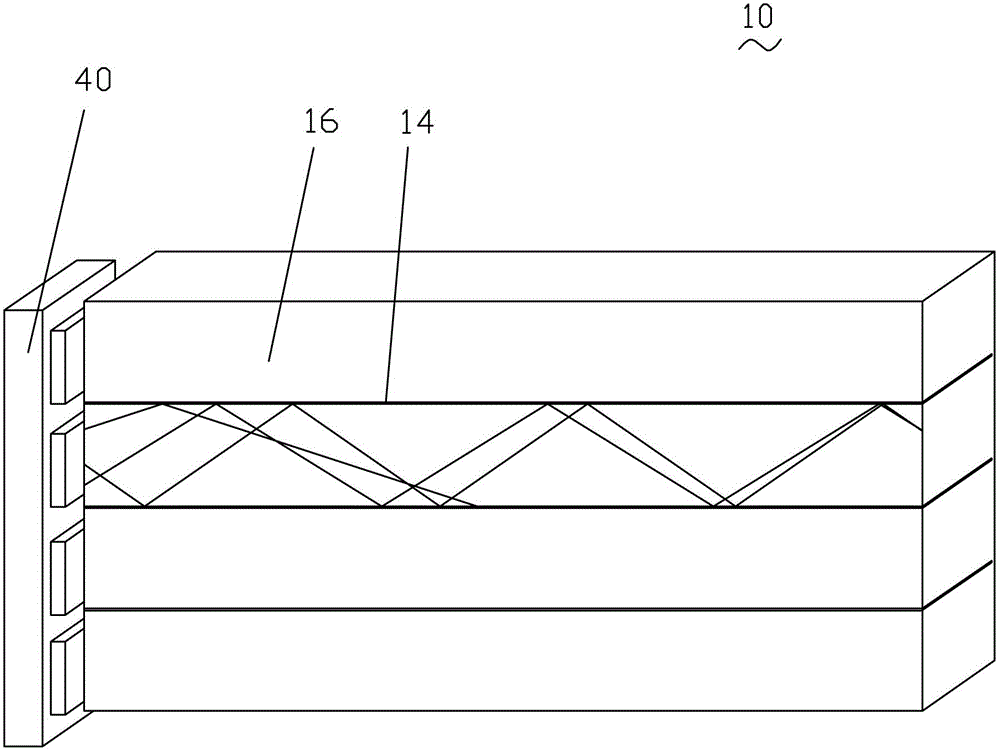

[0040] see Figures 1 to 3 , the present invention provides a light guide plate 10 on which several reflective partition walls 14 are arranged, and the light guide plate 10 is divided into several partitions 16 by the reflective partition walls 14 . The number of reflective partition walls 14 is set accordingly according to the number of required partitions 16 .

[0041] The width of the reflective partition wall 14 is smaller than the thickness of the light guide plate 10 . The reflective partition wall 14 is in the shape of a sheet, and its surface is a mirror surface. The reflective partition wall 14 is a metal sheet, and the thickness of the metal sheet is 0.2 mm to 1 mm. In this embodiment, the surface of the metal sheet is polished to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com