Production method for purple sweet potato entire powder

A production method, the technology of purple sweet potato powder, applied in the fields of application, food preparation, food science, etc., can solve the problems of low anthocyanin content, long drying time, high energy consumption, etc., achieve high anthocyanin content, save The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

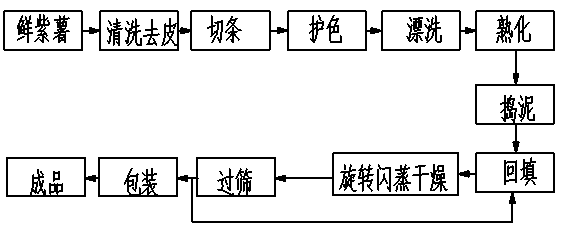

[0022] like figure 1 As mentioned above, fresh purple sweet potatoes are selected, washed, peeled, sliced, and color-protected, and color-protecting agents (0.5% citric acid, 0.1% phytic acid, 0.1% calcium chloride, and the balance is water-dried, mass percent ).

[0023] After color protection, after rinsing, aging, and mashing, it enters the single-axis hammer-bar high-speed mixer to stir and backfill the mixing device. The stirring speed of the mixer is 1300-1500 rpm.

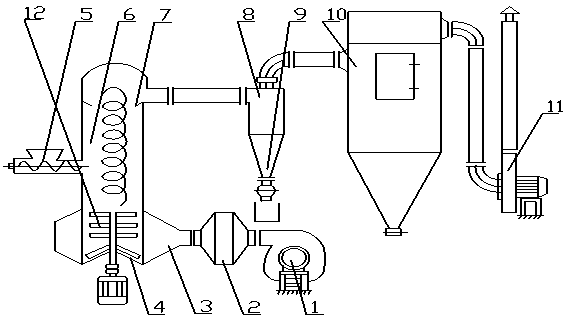

[0024] The material coming out of the mixer enters the spin flash dryer for drying, and the spin flash dryer is dried as figure 2 As shown, the spin flash dryer includes a blower 1, a heater 2, an air distributor 3, a mixer 4, a feeder 5, a dryer 6, a retaining ring 7, a cyclone separator 8, an unloader 9, Bag filter 10 and exhaust fan 11. The entry part of the material coming out of the mixer into the spin flash dryer is the feeder 5 . The material can be dried into a granular powder with a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com