Snail sauce and process for processing same

A processing technology and technology of snail meat, which is applied in the field of snail sauce and its processing technology, can solve the problems of short shelf life, long shelf life, and microbial indicators that do not meet the requirements of the new national standard, and achieve the effect of high food safety and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

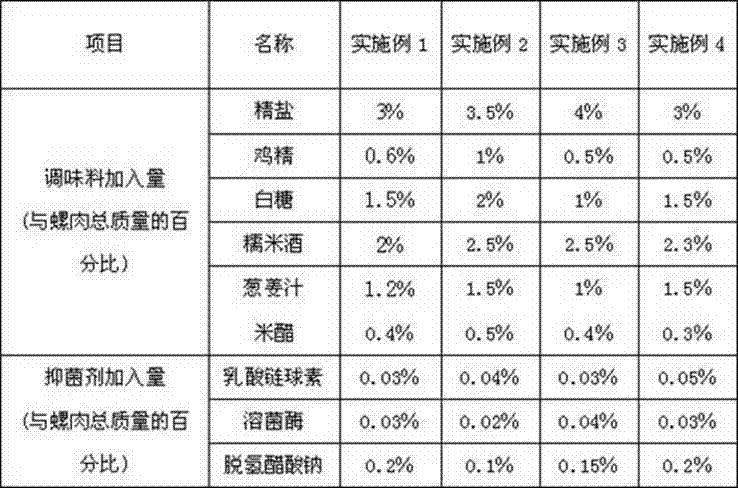

[0043] Select live yellow snails with an individual weight of 15g or more, with hypertrophy of the stomach and feet, no sand in the body, full of belly meat, and no broken shells as the processing raw materials. After washing the fresh yellow snails, they will be kept for 3 days and then rinsed 3 times. Drain the fresh yellow snails and break the shells to take the meat, then break the snail meat into meat pieces, add seasonings and antibacterial agents according to the total mass of the snail meat, and stir them evenly. The added amounts of seasonings and antibacterial agents are shown in Table 1. It is shown that the snail sauce is obtained by marinating the meat at 15°C for 3 days, and finally the snail sauce is bottled and capped to obtain the finished snail sauce.

[0044] The snail sauce was tested for microbiological indicators, and the test results are shown in Table 2.

[0045]

Embodiment 2

[0050] Select live yellow snails with an individual weight of 15g or more, with thick stomachs and feet, no sand in the body, full belly, and no broken shells as raw materials for processing. After washing the fresh yellow snails, they will be kept for 2 days, then rinsed 3 times, and then Drain the fresh yellow snails and break the shells to take the meat, then break the snail meat into meat pieces, add seasonings and antibacterial agents according to the total mass of the snail meat, and stir them evenly. The added amounts of seasonings and antibacterial agents are shown in Table 1. It is shown that the snail sauce is obtained by marinating the meat at 10°C for 4 days, and finally the snail sauce is bottled and capped to obtain the finished snail sauce.

[0051] The microbiological indicators of the snail sauce were tested, and the results are shown in Table 2.

[0052]

Embodiment 3

[0057] Select live spicy snails with an individual weight of more than 15g, thick stomachs and feet, no sand in the body, full belly and no shells as raw materials for processing, wash and drain the fresh spicy snails, and then crack the fresh spicy snails to get the meat , Then crush the snail meat into meat pieces, add seasonings and bacteriostatic agents according to the total mass of the snail meat, and stir them evenly. The added amounts of seasonings and bacteriostatic agents are shown in Table 1. The meat pieces are marinated at 10°C The snail sauce was obtained in 3 days, and finally the snail sauce was bottled and capped to obtain the finished snail sauce.

[0058] The snail sauce was tested for microbiological indicators, and the test results are shown in Table 2.

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com