New vertical mill grinding device

A vertical grinding and grinding technology, applied in grain processing and other directions, can solve the problems of reducing the working efficiency of vertical grinding, bed instability, energy waste, etc., to improve grinding efficiency and output, save energy consumption, and prolong residence time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

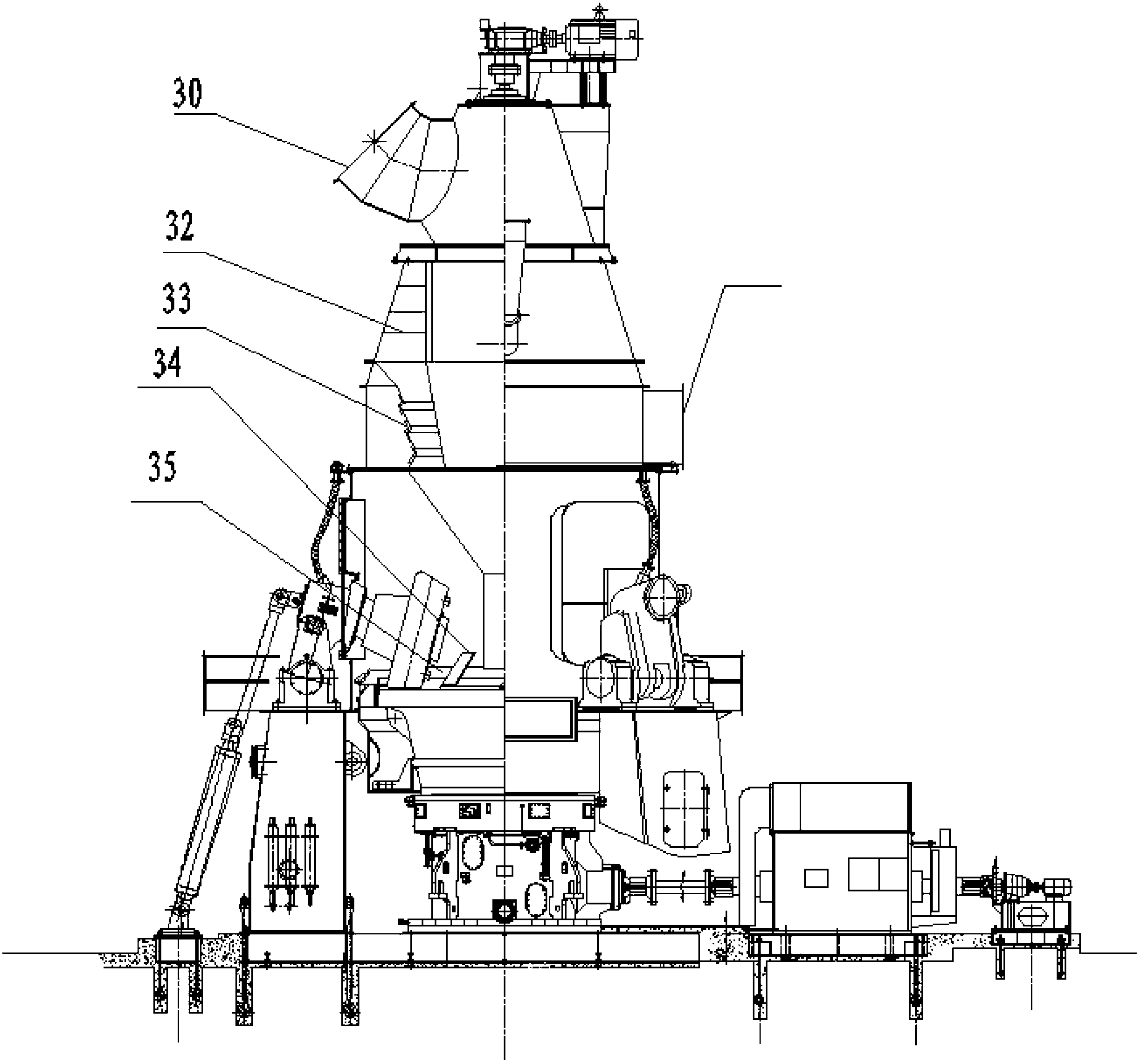

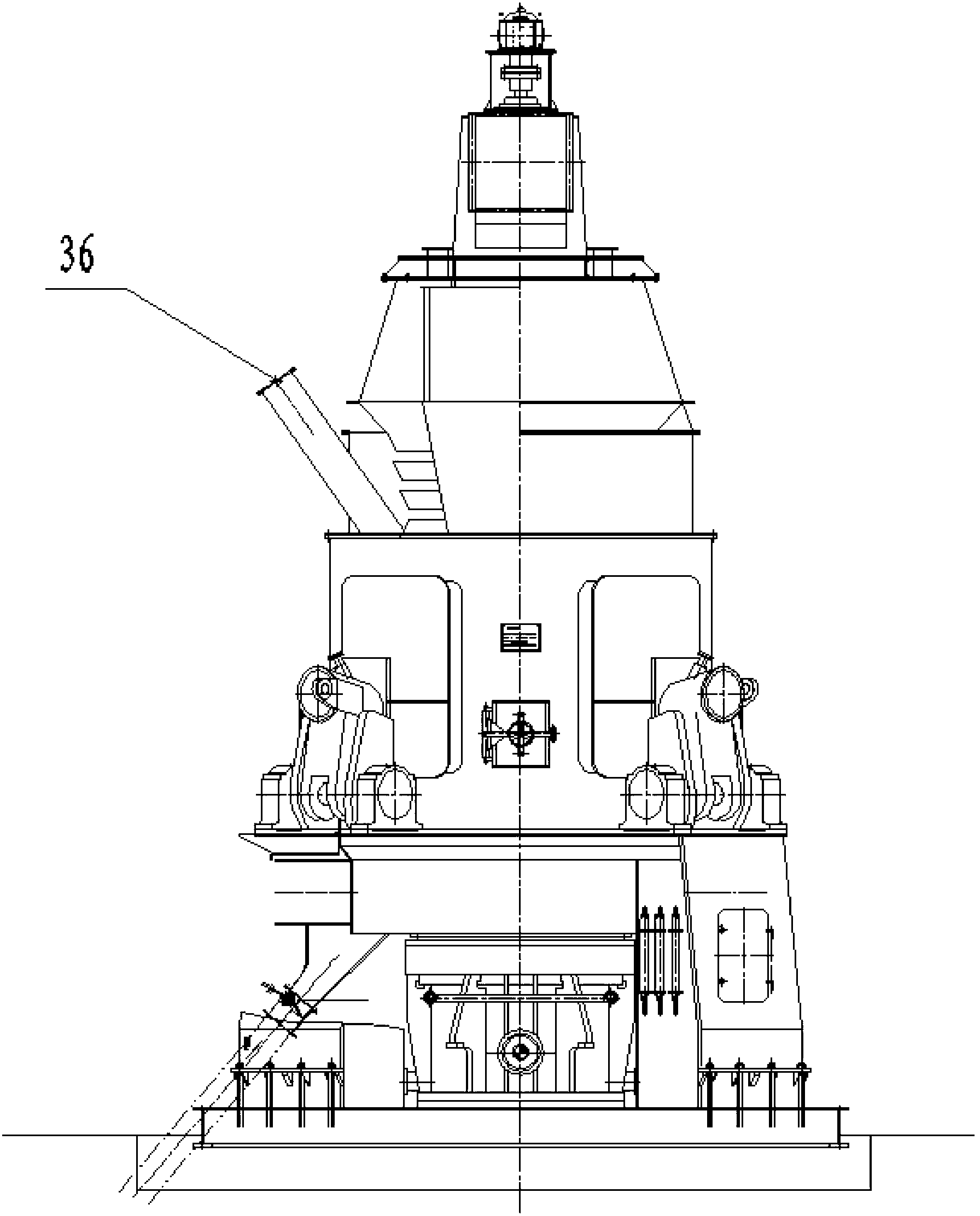

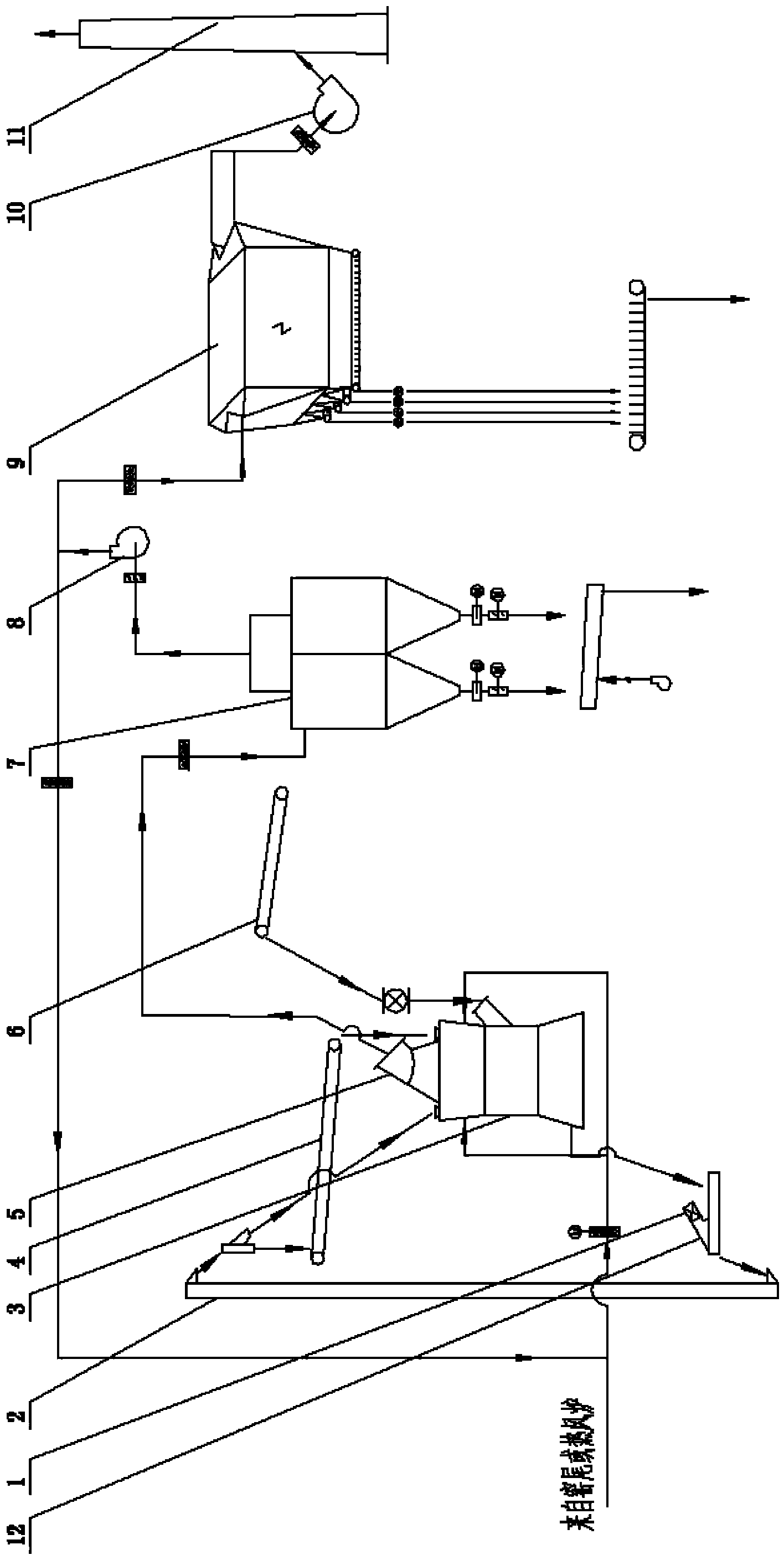

[0030] Such as Figures 1 to 3 , a new vertical mill grinding device, including a mill lifter 2, a vertical mill 3, a powder separator conveyor 4, a multifunctional separator 5, a raw material conveyor 6, a cyclone dust collector 7 and a circulating fan 8 , the top of the mill elevator 2 is connected to the vertical mill 3 through the powder classifier conveyor 4, the raw material conveyor 6 is connected to the feed port 36 of the vertical mill 3, and the upper part of the vertical mill 3 is provided with an air inlet 31, the The air inlet 31 is connected with the hot air outlet from the kiln tail or the hot blast stove, the air outlet 30 at the top of the vertical mill 3 is connected with the cyclone dust collector 7, and the top of the cyclone dust collector 7 is connected with the circulation fan 8.

[0031] The vertical mill grinding device also includes a mill belt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com