Laser double-consumable-electrode single-arc bypass-coupling hybrid welding system and method

A hybrid welding and bypass coupling technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of laser power reduction, filler metal amount reduction, laser utilization rate reduction, etc., to achieve control of weld formation, The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

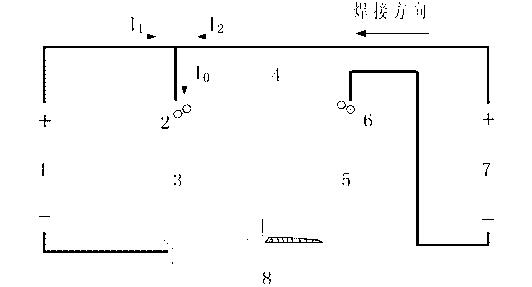

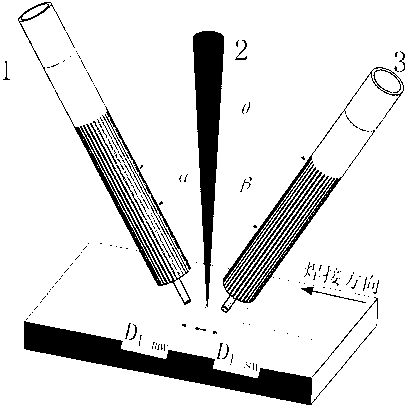

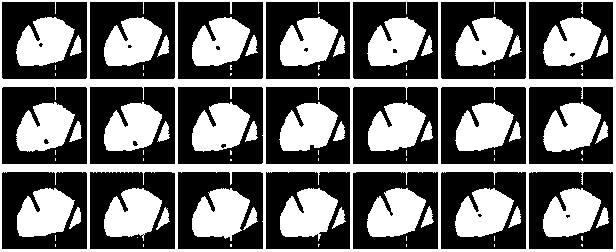

[0047] The composite welding system used in the present invention includes the following components: Nd:YAG laser of JK2003SM (1 set), Lincoln INVERTEC V350 PRO welding machine (1 set), Lincoln INVERTEC TM V300-I welding machine (1 set), S-86A semi-automatic wire feeder (2 sets), angle and position adjustable double gun fixture (1 set), workbench (1 set). In addition, it also includes welding auxiliary equipment such as gas cylinder valve, remote control box, etc. The welding wire is selected from H08Mn2SiA welding wire, and the workpiece is selected from Q235 steel. use as figure 1 The method shown is connected into a welding system, and the specific parameters of the welding process are shown in Table 1 and Table 2. collected during the test and Figure 4 The comparison between the laser power and the electrical signal parameters in the corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com