Semi-automatic error correction braking system with inward rotating solenoid valve having fixed rotation angle

A braking system and solenoid valve technology, applied in the field of error correction braking system, can solve the problems of complex structure, low practicability, and many microelectronic devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

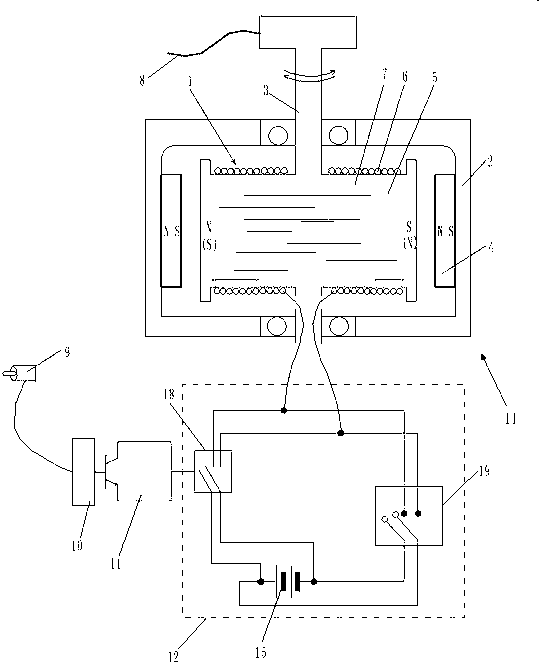

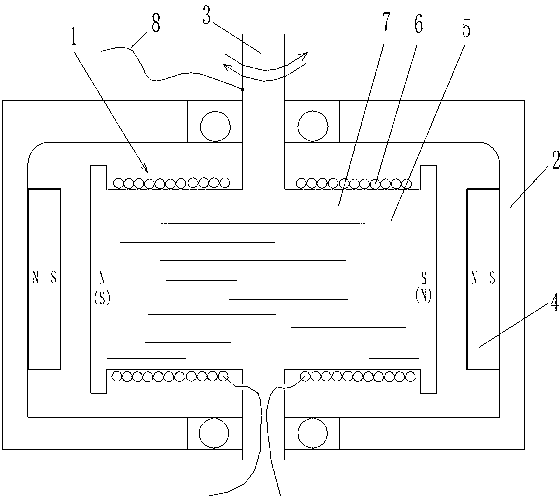

[0046] Embodiment 1. Semi-automatic error correction braking system for internally rotating fixed angle solenoid valve

[0047] Such as figure 1 , 2 , 3, including the sensor 9---sensing signal analyzer 10---control signal power amplifier 11---power controller 12 connected successively in order to transmit electrical signals, and in order to convert electrical energy into mechanical energy, use The power controller 12 is connected with the solenoid valve 14 whose inner fork-shaped rotating body is a fixed angle of rotation, and the power controller 12 is connected with the DC power supply 15 that drives the electromagnetic valve 14 whose inner fork-shaped rotating body is a fixed angle of rotation.

[0048] The following is a description of each part:

[0049] The sensor 9 is one of a pressure sensor, a speed sensor or an acceleration sensor or a combination thereof; the sensor 9 transmits a sensing signal to a sensing signal analyzer 10 . That is to say, sensor 9 is to use...

Embodiment 2

[0059] Embodiment 2, semi-automatic error correction braking system of internal rotation fixed angle solenoid valve

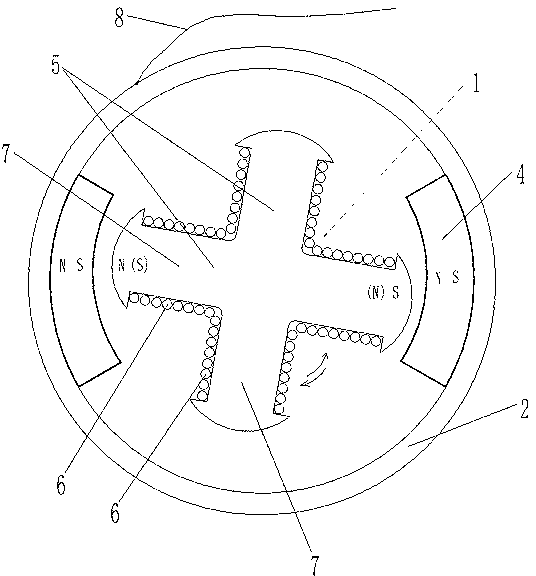

[0060] As in embodiment 1, after the two coils 6 wound in the same direction are penetrated respectively from the two ends of a straight iron core 7, a coil larger than the straight iron core 7 is respectively fixed at the two ends of the straight iron core 7. Core 7 cross-sections, the gear coil block identical with straight iron core 7 materials, make this straight iron core 7 become " I " font. Also carry out the same process to another straight iron core 7, also become " I " font straight iron core 7.

[0061] The outer surface of the rotating shaft 3 of the inner fork-shaped rotating body 1 is fixedly connected with one end of a stay cord 8, and the other end of the stay cord 8 is connected with the driven object. When the inner fork-shaped rotating body 1 is rotated at an angle of 80 degrees, the stay cord 8 is pulled at an angle of 80 degrees correspond...

Embodiment 3

[0062] Embodiment 3, semi-automatic error correction braking system of internal rotation fixed angle solenoid valve

[0063] As embodiment 1, but only the inner fork-shaped rotating body is the minimum included angle of the "cross" shaped piece of the solenoid valve 14 of fixed rotation angle and changes it into 10 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com