Production process of high-purity sweet tea glycosides

A production process and high-purity technology, which can be used in the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, and can solve the problems of difficulty in industrialization, high cost, and cumbersome production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

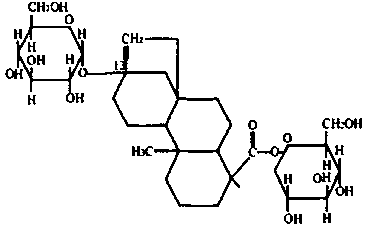

Image

Examples

Embodiment 1

[0029] A production process for extracting high-purity rubusoside from Guangxi sweet tea leaves, comprising the following steps:

[0030] (1) Extraction: Take 1000kg of Guangxi sweet tea leaves, crush them and put them into an extraction tank, use tap water to extract 3 times in a slightly boiling state, add 8, 6, and 7 times the amount of tap water, and extract the first batch of materials for the third time As the first extraction solution of the second batch of materials, the extraction time is 1.5h, 1h, and 1h respectively, and the filter residue after each filtration enters the next extraction;

[0031] (2) Concentration: Concentrate the first two Guangxi sweet tea extracts to three times the weight of the dry sweet tea leaves, about 3000L;

[0032] (3) Flocculation and clarification: Cool the concentrated solution to 40~45°C, and then turn on the steam to keep the temperature within this range; add 0.3% water-soluble chitosan by weight of Guangxi sweet tea raw material, ...

Embodiment 2

[0045] A production process for extracting high-purity rubusoside from Guangxi sweet tea leaves, comprising the following steps:

[0046] (1) Extraction: Take 1000kg of Guangxi sweet tea leaves, crush them and put them into an extraction tank, use tap water to extract 3 times in a slightly boiling state, add 8, 6, and 7 times the amount of tap water, and extract the first batch of materials for the third time As the first extraction solution of the second batch of materials, the extraction time is 1.5h, 1h, and 1h respectively, and the filter residue after each filtration enters the next extraction;

[0047] (2) Concentration: Concentrate the first two Guangxi sweet tea extracts to three times the weight of the dry sweet tea leaves, about 3000L;

[0048](3) Flocculation and clarification: Cool the concentrated solution to 40~45°C, and then turn on the steam to keep the temperature within this range; add 0.3% water-soluble chitosan by weight of Guangxi sweet tea raw material, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com