Styrene-butadiene asbestos heat-resisting composite rubber and preparation method thereof

A technology of composite rubber and styrene-butadiene asbestos, which is applied in the field of thermal protection materials for rocket engines, can solve the problems of low tensile strength, elongation at break and failure to meet product performance requirements, etc., and achieve excellent thermal insulation performance , slow vulcanization speed, and flat vulcanization curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

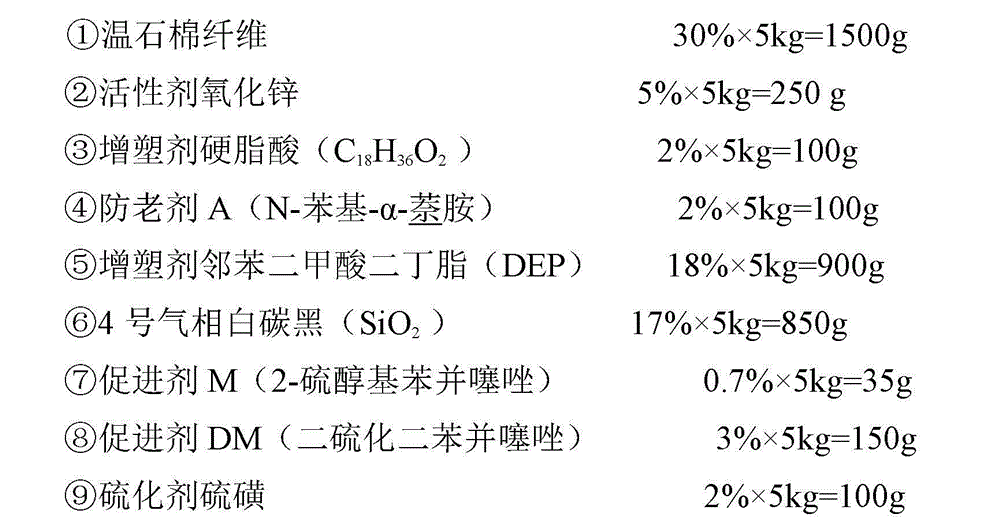

[0023] A styrene-butadiene asbestos heat-resistant composite rubber, the main material contained styrene-butadiene rubber has a mass of 5kg, and the mass ratio of other raw materials is calculated as follows:

[0024]

[0025] The preparation method of preparing the above-mentioned materials into styrene-butadiene asbestos heat-resistant composite rubber comprises the following steps in turn:

[0026] 1) Plasticizing styrene-butadiene rubber: pass the broken styrene-butadiene rubber on the open mill for 4-6 times with a small roll distance of 0.5-1.0mm, and then add 2-mercaptobenzothiazole and Dibenzothiazole disulfide, after each stage of feeding, pass through a triangular bag, and control the temperature of the roller at 30~40°C;

[0027] 2) Mix dibutyl phthalate (DEP) and chrysotile fiber evenly to make it fully saturated with chrysotile fiber to make a pre-mixture of chrysotile fiber; adjust the roller distance of the mill to 0.5~1.0mm again, Add active agent zinc oxid...

Embodiment 2

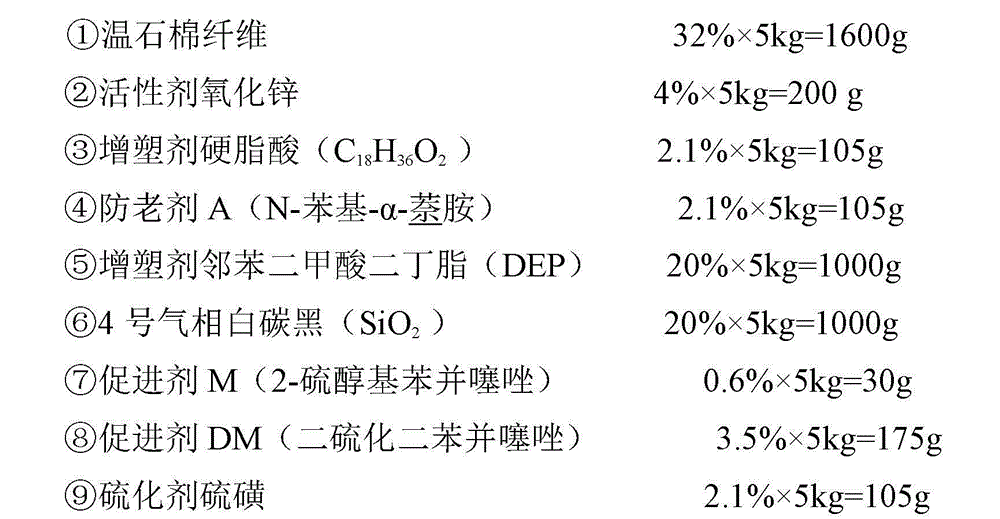

[0029] A styrene-butadiene asbestos heat-resistant composite rubber, the main material contained styrene-butadiene rubber has a mass of 5kg, and the mass ratio of other raw materials is calculated as follows:

[0030]

[0031] The preparation method of preparing the above materials into styrene-butadiene asbestos heat-resistant composite rubber is the same as that in Example 1.

Embodiment 3

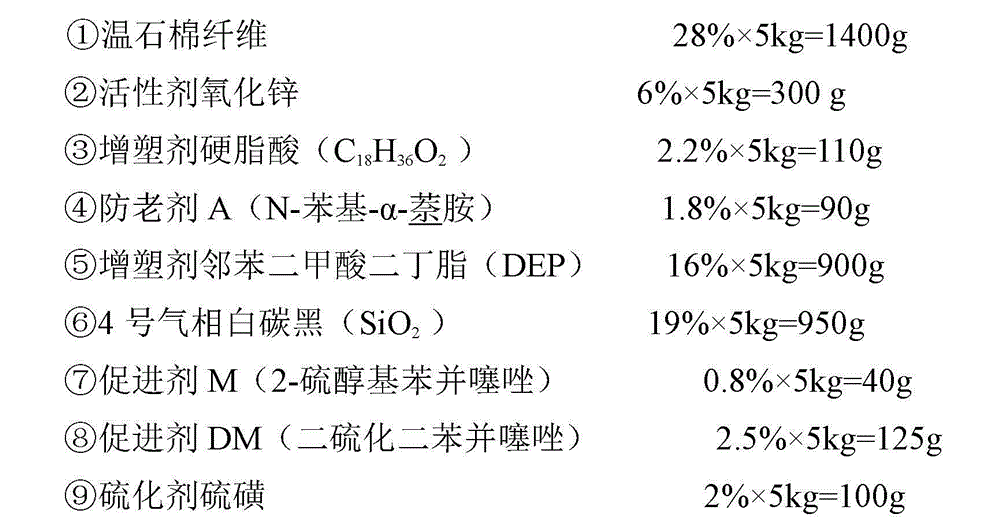

[0033] A kind of styrene-butadiene asbestos heat-resistant composite rubber, the contained main material styrene-butadiene rubber quality is 5kg, other raw material ratio quality except the following items, other are identical with embodiment 1:

[0034]

[0035] The preparation method of preparing the above materials into styrene-butadiene asbestos heat-resistant composite rubber is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com