Halogen-free flame-retardant polyolefin cable material capable of resisting 150 DEG C and preparation method thereof

A technology of polyolefin cable material and cable material, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc. It can solve the problems that the performance of cables that cannot withstand 150°C and that cables cannot be used in high-temperature occasions, etc., and achieve excellent durability. Effects of high temperature performance, improvement of temperature resistance performance, and improvement of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described.

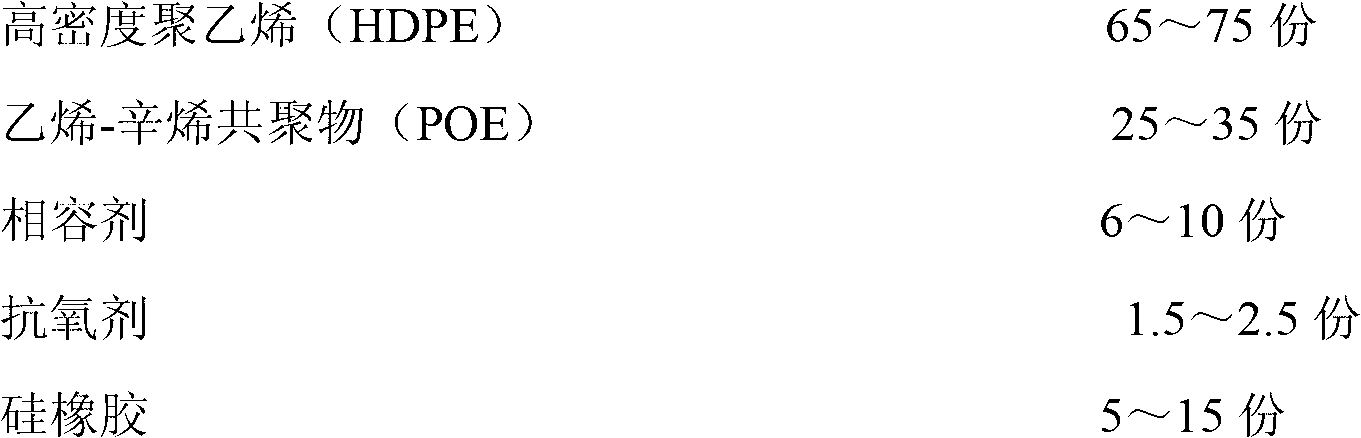

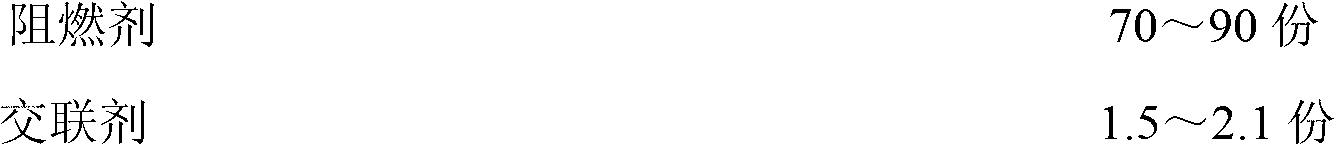

[0018] A 150°C-resistant halogen-free flame-retardant polyolefin cable material, its raw material formula (parts by weight) is shown in Table 1:

[0019] Table 1

[0020]

[0021]

[0022] The preparation method of above-mentioned cable material is:

[0023] According to the total weight of 50g, mix HDPE, POE and compatibilizer evenly, then put it into the internal mixer for 5-10 minutes (mixing temperature 150°C-160°C), and then add silicone rubber, antioxidant, resistance The fuel and crosslinking agent are discharged after the torque is balanced, and the cable material is prepared through the extruder granulation production line.

[0024] Its main properties are shown in Table 2:

[0025] Table 2

[0026]

[0027]

[0028] It can be seen from Table 2 that the experimental results can meet the relevant technical regulations in the JB / T 10491.1-2004 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com