Shear wall with 'profile steel column-steel beam-steel support' embedded between steel tube concrete columns and manufacturing method

A technology of concrete-filled steel tube columns and concrete-filled steel tubes, which is applied to walls, building components, buildings, etc., to achieve the effects of good stability of later bearing capacity, improvement of elastic initial stiffness, and optimization of energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiment:

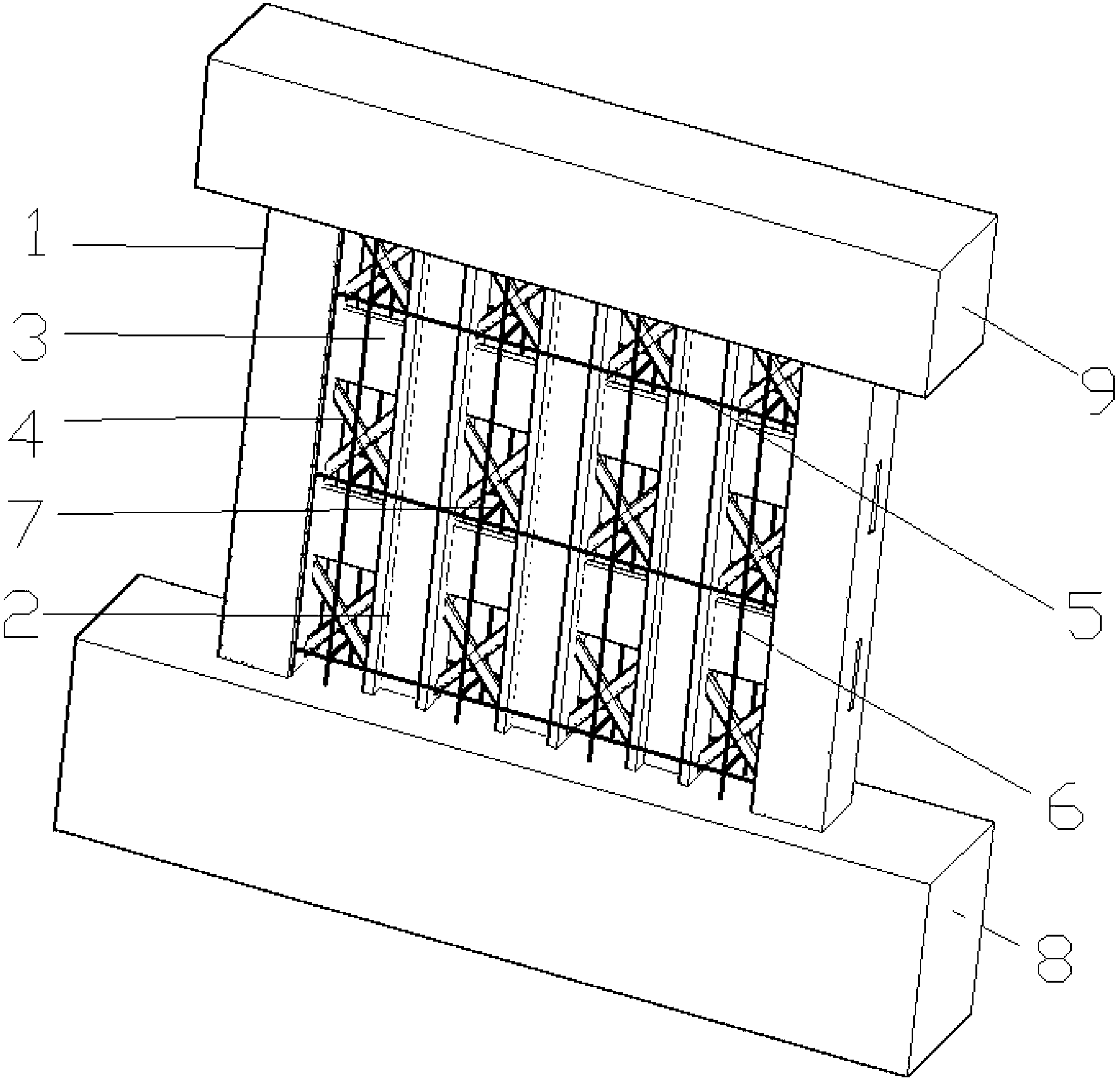

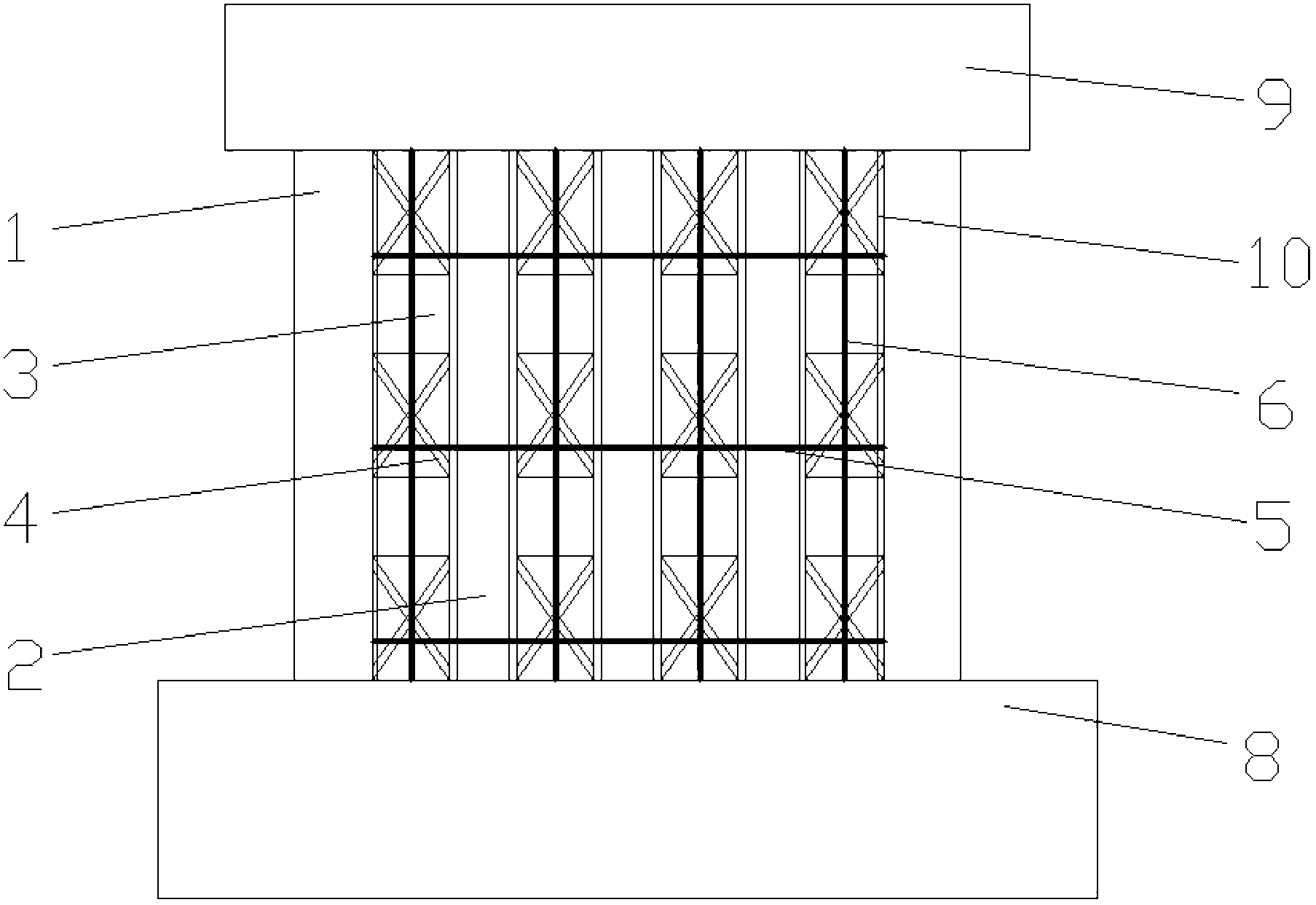

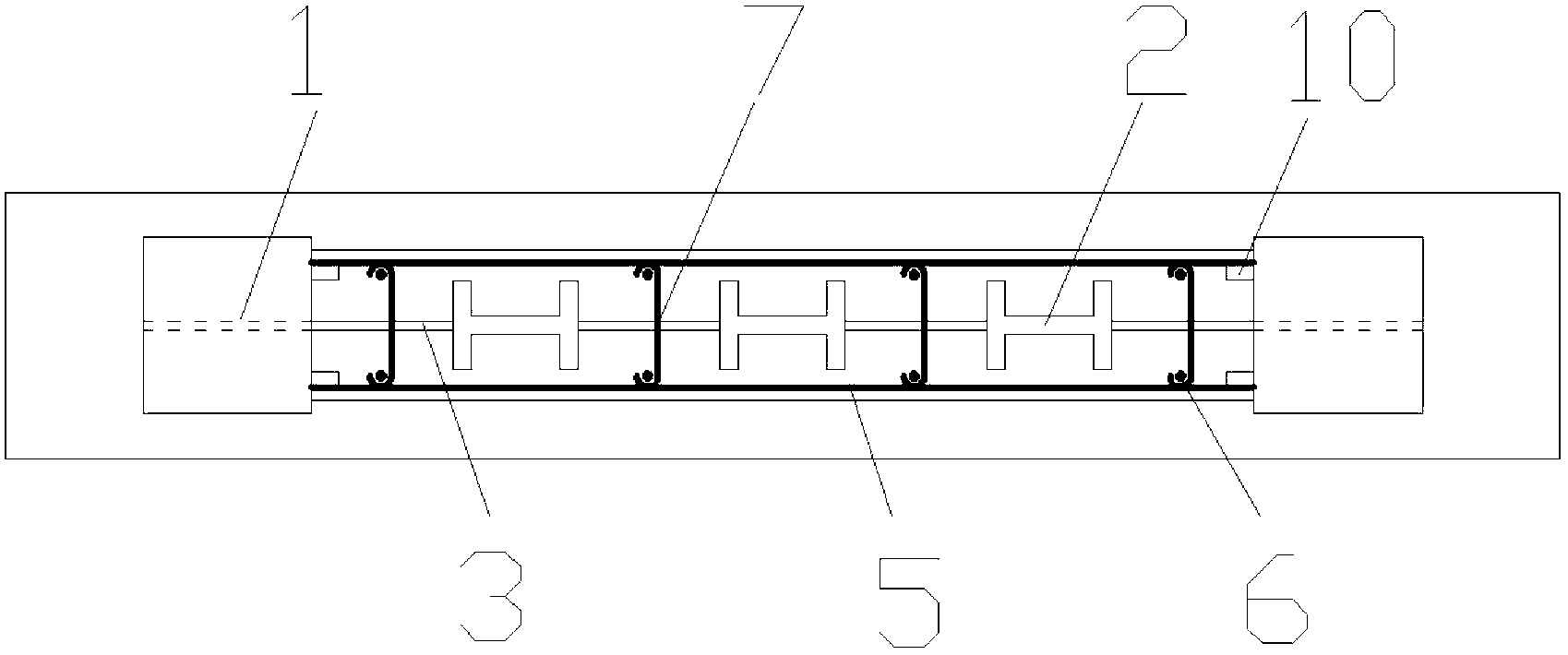

[0037] A structural unit of the "steel column-steel beam-steel brace" shear wall embedded between steel tube concrete columns is as follows: Figure 1-Figure 6 shown.

[0038] The "steel column-steel beam-steel brace" shear wall is embedded between the steel tube concrete columns, and the fabrication sequence is as follows:

[0039] 1) Fabricate the CFST frame column 1 and the steel core column 2, weld and connect horizontally distributed steel bars 5 on the side steel plate of the CFST frame column 1 and vertically connect the steel plates 10, and the steel vertically connecting steel plates and the CFST frame column 1 adopt steel of equal strength;

[0040] 2) Bind the vertically distributed steel bars 6 of the shear wall, the steel bars of the lower frame beam or the foundation beam 8, and insert the steel pipe concrete frame column 1, the steel core column 2, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com