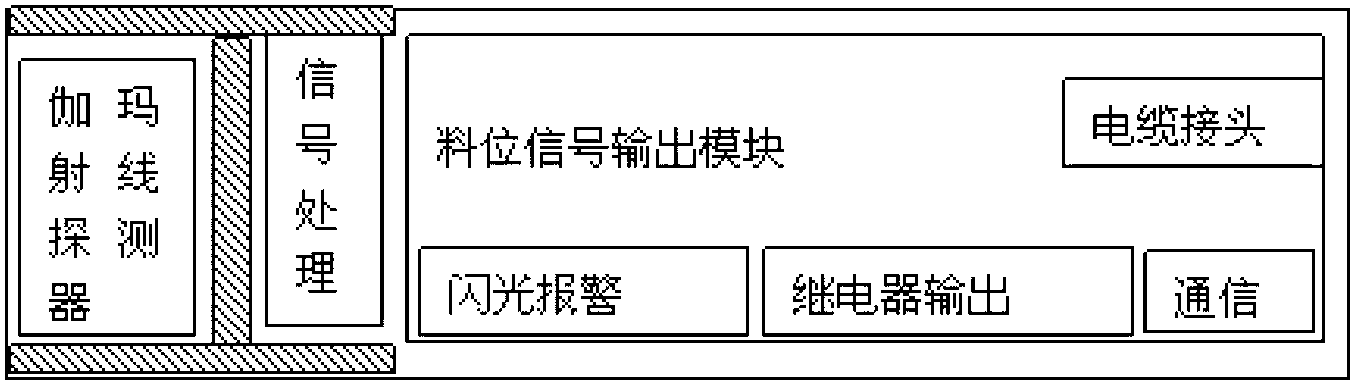

Method referring to determine switching point of switch type passive nucleon material level gage

A material level gauge and switch type technology, which is applied in the field of determining the switch point of the switch type passive nuclear material level gauge, to achieve the effect of improving reliability and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

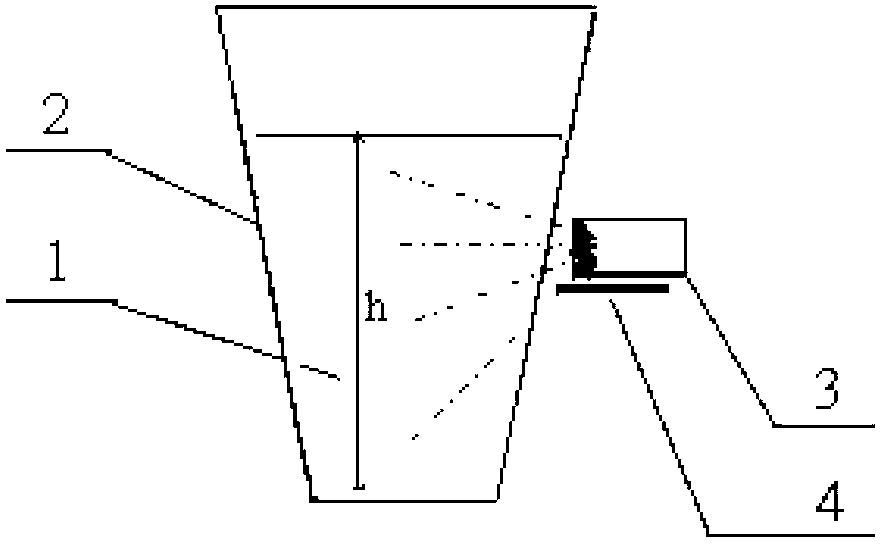

[0050] Use the mobile positioning method to determine the switch point of the full-fill alarm of the switch-type ash hopper level gauge. In the system debugging stage, considering the safety, it is not allowed to accumulate ash to the installation position of the level gauge. The specific operation steps are as follows:

[0051] (1) Remove the switch-type ash hopper level gauge from the installation position, and move it under the installation position to monitor the ash hopper;

[0052] (2) When there is no fly ash in the ash hopper, the gamma ray intensity values measured at each height are basically the same;

[0053] (3) When the amount of fly ash in the ash hopper increases, the gamma ray intensity value measured by the level gauge in the lower area with fly ash or close to the area with fly ash is greater than the gamma ray intensity value in the upper area without fly ash;

[0054] (4) With the increase of fly ash, the material level of the ash hopper rises, and the ...

Embodiment 2

[0059] The warehouse pump or pneumatic conveying tank is used to convey the fly ash accumulated in the ash hopper. The working conditions require that the fly ash is full to 2 / 3 or 3 / 4, and the alarm is released when the fly ash is completely emptied. Considering the climate in the south, the steel outer wall of the warehouse pump is directly exposed to the outside, and the height of the ash inside can be determined by the knocking method, which is the height of the material level. The mobile positioning method is another method used in this paper when the material level cannot be determined to be higher than the set position. method, so the direct hysteresis method can be used to determine the full-fill alarm point and full-fill alarm release point of the switch-type warehouse pump level gauge, including the following steps:

[0060] (1) Install the switch-type warehouse pump material level gauge at the selected position. When there is no ash in the warehouse pump, measure the...

Embodiment 3

[0064] Usually the ash hoppers in the third and fourth electric fields have a very small amount of ash falling, and it is difficult to have a chance of ash accumulation in a short period of time. However, these ash hoppers are very close to the ash hoppers of the first and second electric fields. The determined switch point is used for reference as the full-fill alarm point and full-fill alarm release point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com