Performance correction method for gold mark immunochromatographic test strip detection system

An immunochromatography test strip and detection system technology, which is applied in the field of performance calibration of the gold standard immunochromatography test strip detection system, can solve the problems of the detection system such as large measurement errors, inconvenient operation, and data that cannot be processed in real time, so as to reduce the measurement error, to ensure the effect of accurate quantitative measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A photodiode is adopted as a kind of photodetector, and the present invention is described in detail by taking a photodiode as an example.

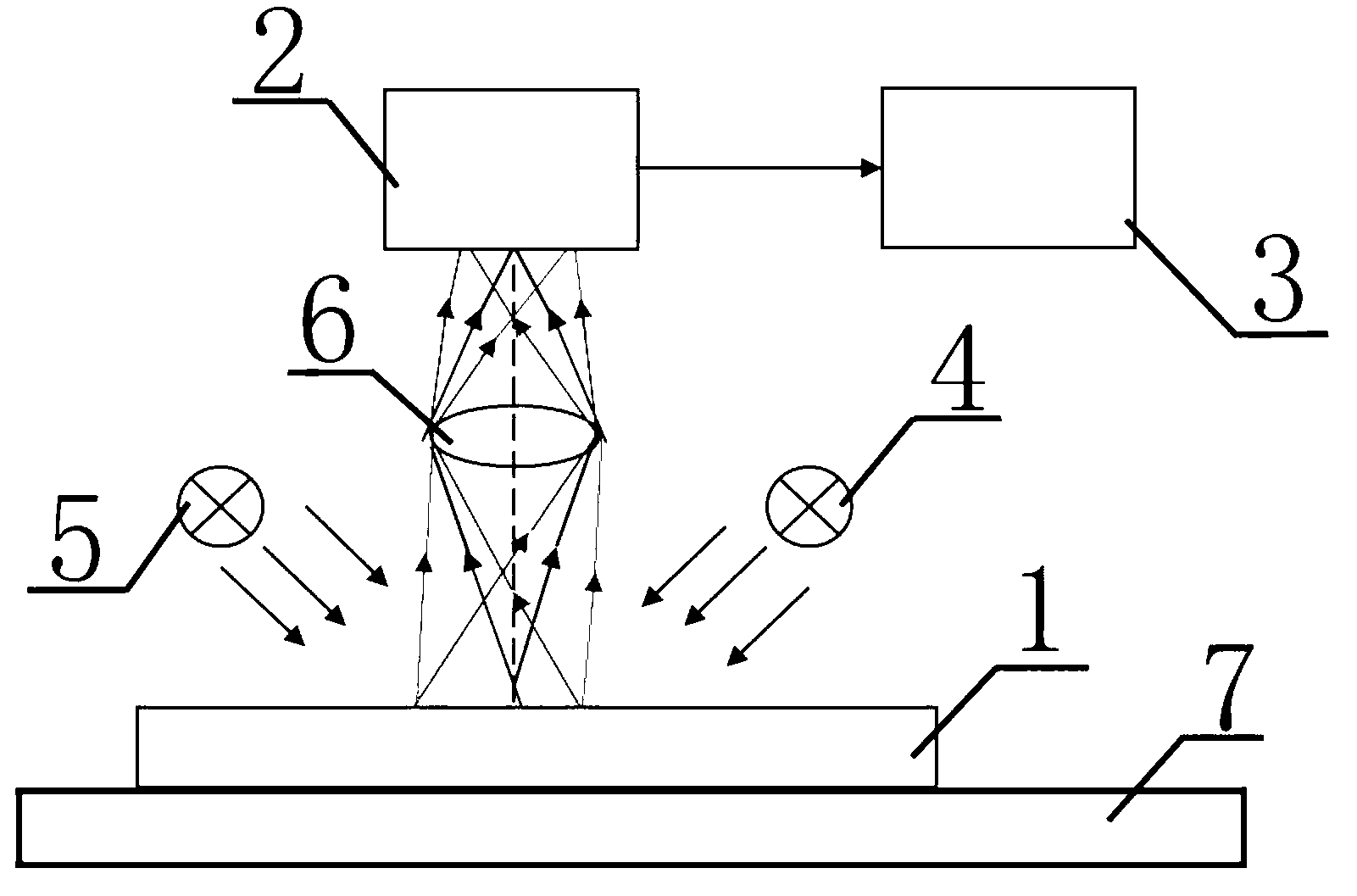

[0039] see figure 1 , figure 1 It is a structural schematic diagram of the gold standard test strip detection system involved in the present invention. Depend on figure 1 It can be seen that the gold standard test strip detection system includes a gold standard strip color card 1, a photodiode 2, a signal processing system 3, lighting components 4, 5, an imaging optical system 6 and a moving component 7. The signal processing system 3 is mainly used for collecting and calculating the output signal of the photodiode 2 and controlling the photodiode 2 . The collected signal is calculated by the algorithm to obtain the standard data. The moving part 7 is mainly used for the translation of the gold label color card 1 .

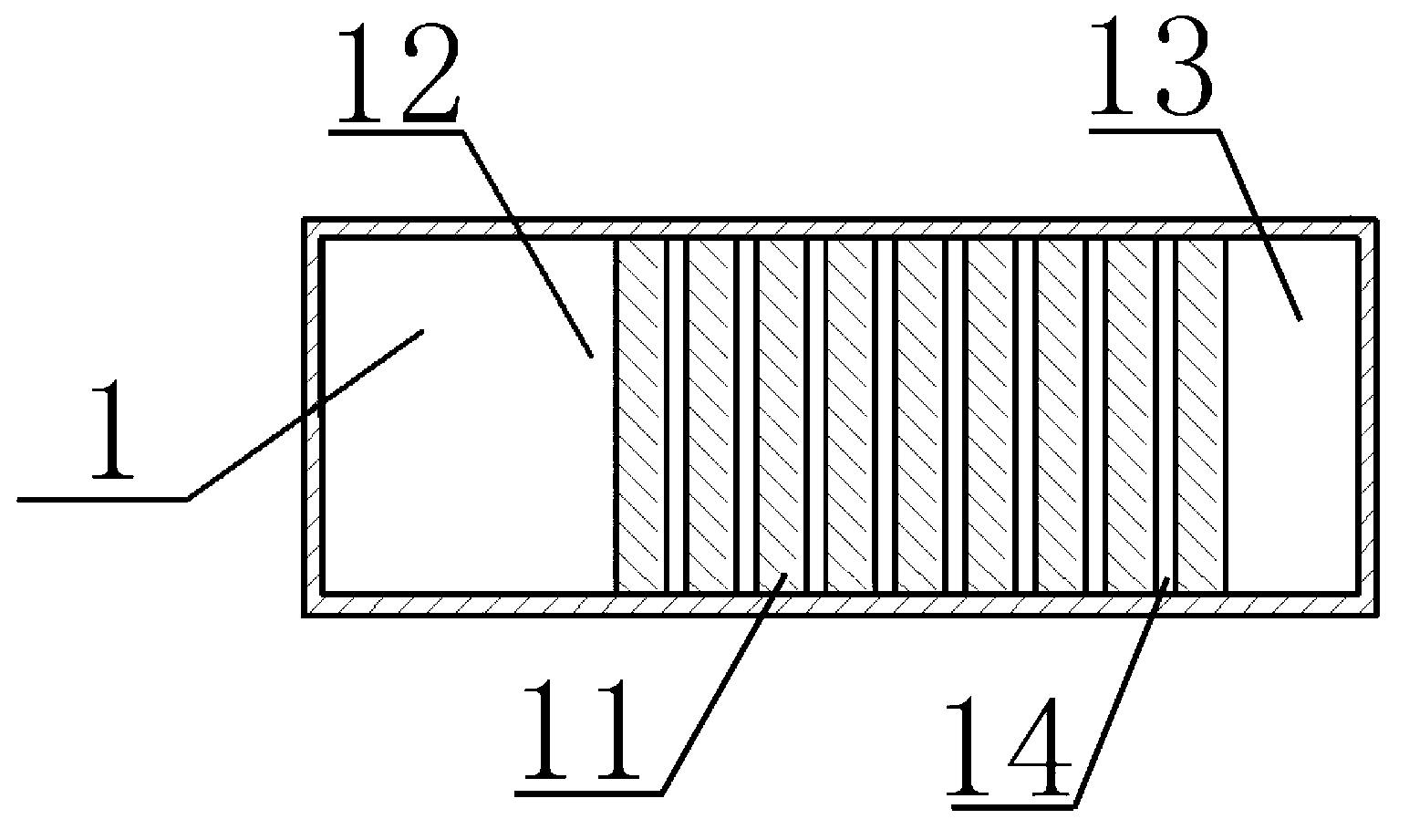

[0040] The shape and structure of the gold standard strip color card 1 is exactly the same as the gold standard...

Embodiment 2

[0057] The image sensor is a kind of photodetector, and the present invention will be described in detail by taking the image sensor as an example.

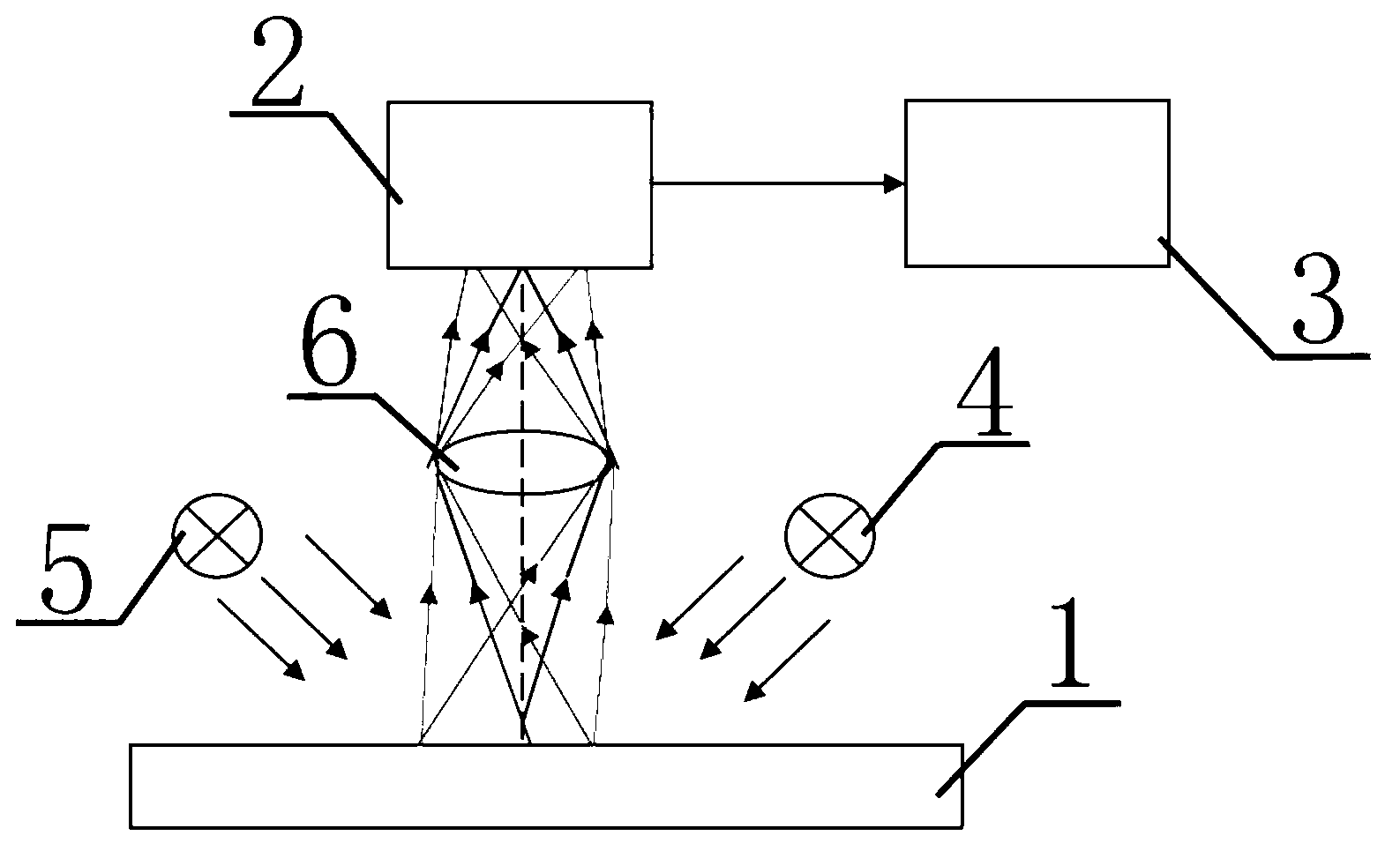

[0058] see figure 2 , figure 2 It is a structural schematic diagram of the gold standard test strip detection system involved in the present invention. Depend on figure 2 It can be seen that the detection system is composed of a gold label color card 1 , an image sensor 2 , a signal processing system 3 , lighting components 4 and 5 and an imaging optical system 6 .

[0059] The gold label color chart 1 is the same as that described in Example 1.

[0060] see Figure 4 , Figure 4 It is a structural schematic diagram of the colloidal gold immunochromatography test strip involved in the present invention. Depend on Figure 4 It can be seen that 83, 84 and 85 are non-functional areas. 81, 82 represent the functional area of the test strip.

[0061] The signal processing system 3 is mainly used to collect the output dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com