Peeling turning module of multifunctional automatic wire ranging terminal pressing machine

A terminal crimping machine, fully automatic technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of low production efficiency, poor quality, high production cost, etc., achieve convenient control, reduce production cost, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

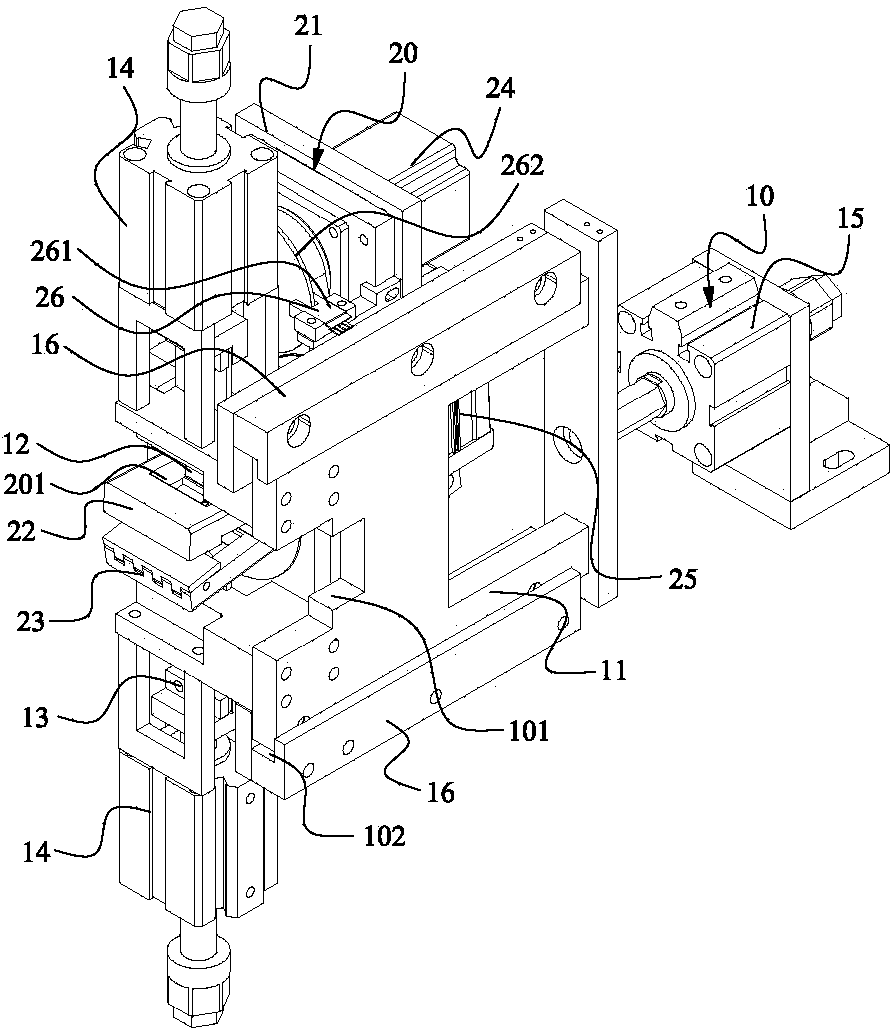

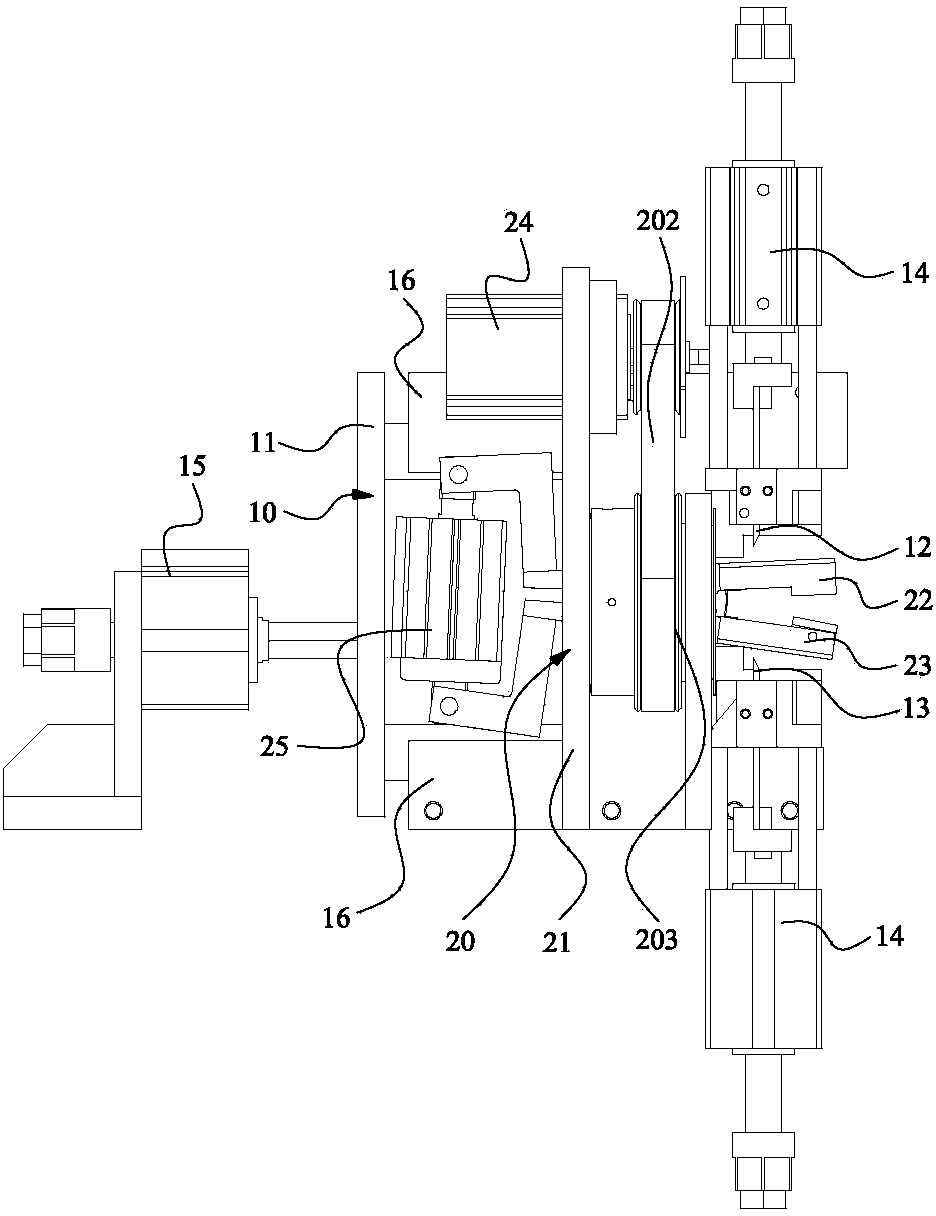

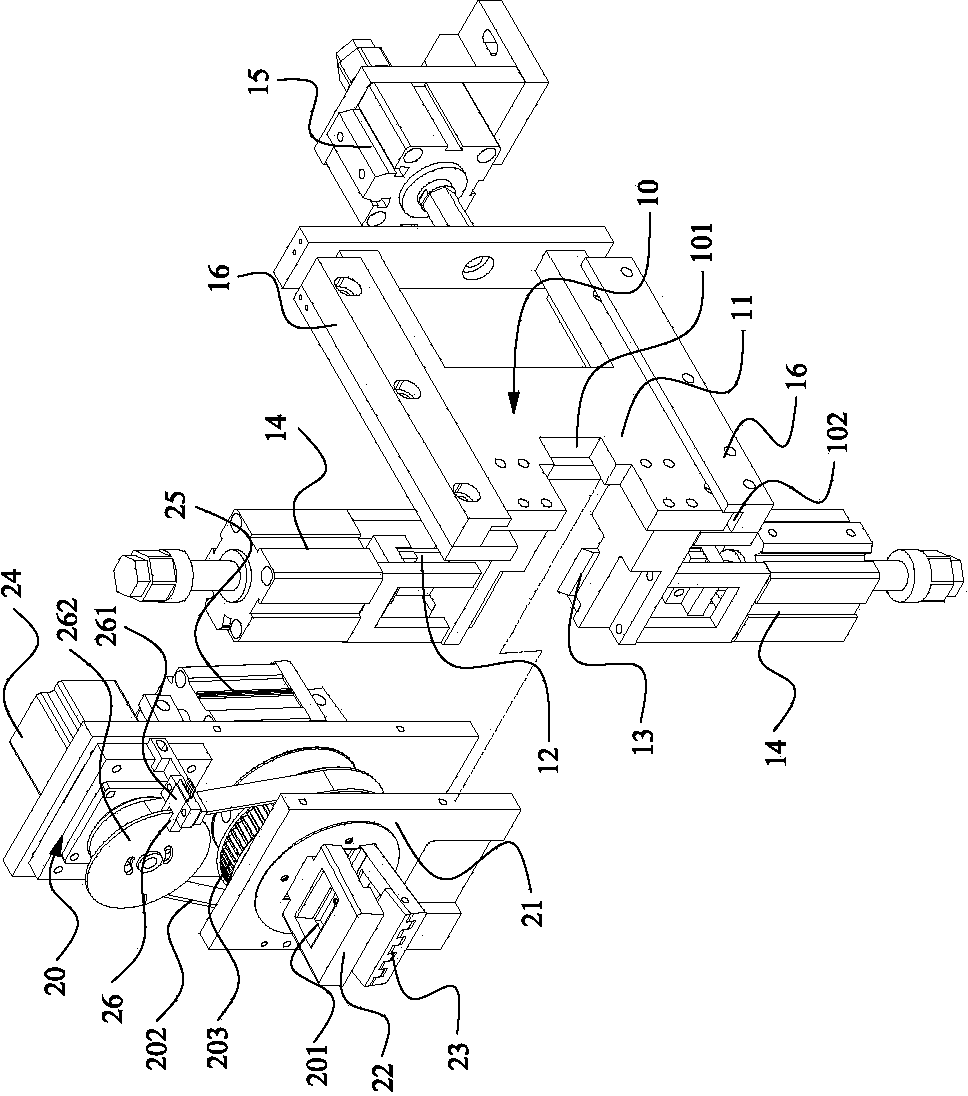

[0034] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is installed on the frame (not shown in the figure) of the multifunctional automatic cable terminal crimping machine for stripping and turning the cable Turn over and include a peeling device 10 and a steering device 20 that are combined with each other and installed on the frame.

[0035] Wherein, the peeling device 10 is used for peeling the wire rods cut on the cable. The peeling device 10 includes a peeling slide 11, a peeling upper knife 12, a peeling lower knife 13, an upper peeling knife 12 and a lower peeling knife 13. Close the first driving mechanism 14 that cuts the outer skin of the cable and impel the second driving mechanism 15 that the peeling slide 11 is longitudinally translated to pull out the outer skin of the cable. The upper knife 12, the lower knife 13 and the first The driving mechanism 14 is all arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com