Production process for hulled peanut kernels

A production process, peanut kernel technology, applied in the field of peeled peanut kernel production technology, can solve the problems of end of shelf life, poor anti-oxidation ability, low quality of peanut products, etc., and achieve the effect of avoiding denaturation, ensuring quality and ensuring fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

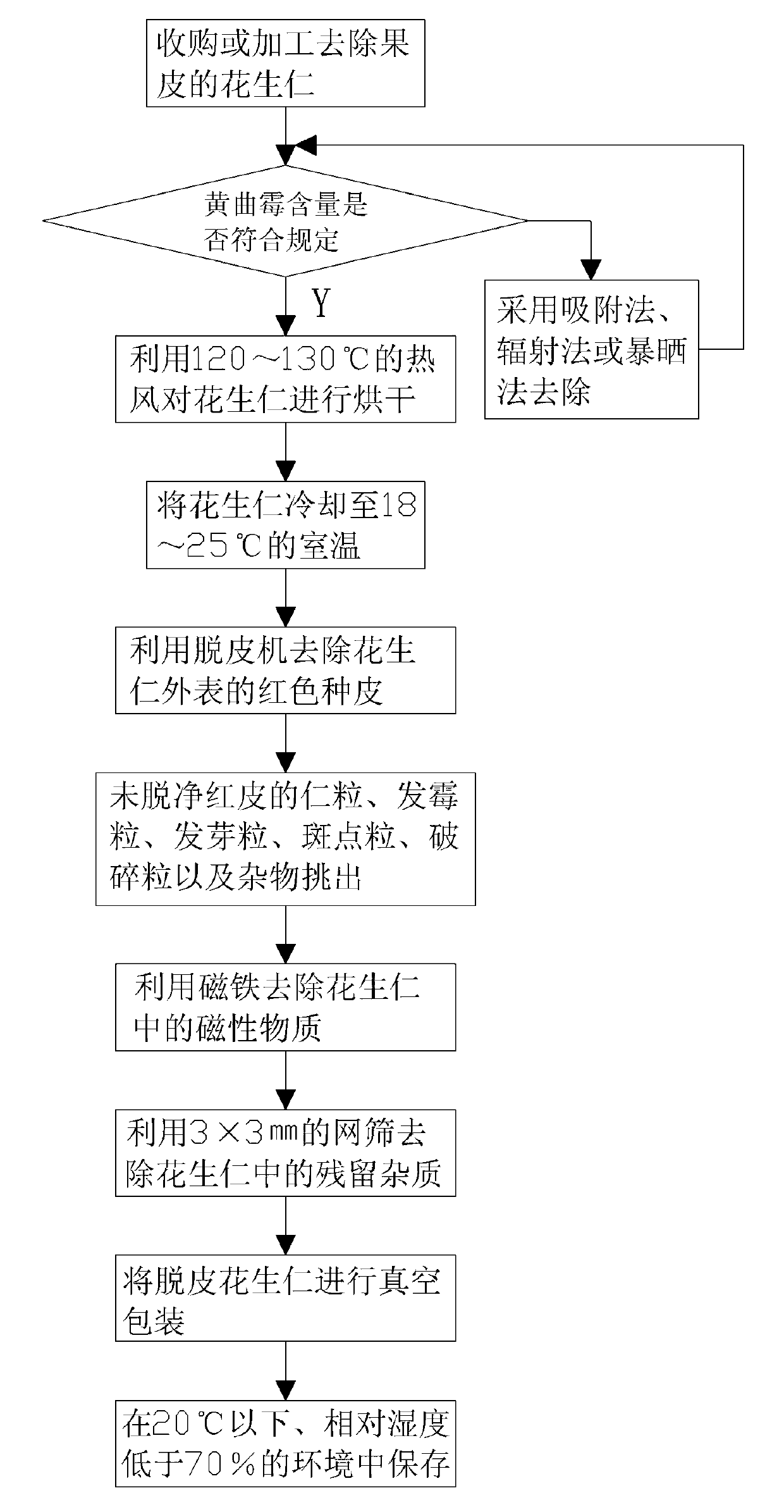

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] Such as figure 1 As shown, the flow chart of the peeling peanut kernel production process of the present invention is provided, and it will be described in detail below in conjunction with the flow chart.

[0013] The production process of peeled peanut kernels of the present invention comprises the following steps:

[0014] a. Obtain peanut kernels, purchase or process peanut kernels with peels removed; peanut kernels can be purchased directly, or processed from peanuts with peels;

[0015] b. Aflatoxin test: Sampling check whether the aflatoxin content in the peanut kernels obtained in step a complies with the regulations. If the content meets the regulations, go to step d; if the aflatoxin content exceeds the standard, go to step c;

[0016] c. To remove aflatoxin, use adsorption method, radiation method or sun exposure method to remove afla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com