High-speed intermittent ultrasonic vibration cutting method for low-rigidity parts

An ultrasonic vibration cutting and processing method technology, applied in the field of high-speed processing, can solve the problems of small cutting line speed, easy deformation and chatter, large margin, etc., to suppress stress deformation and thermal deformation, reduce surface roughness, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

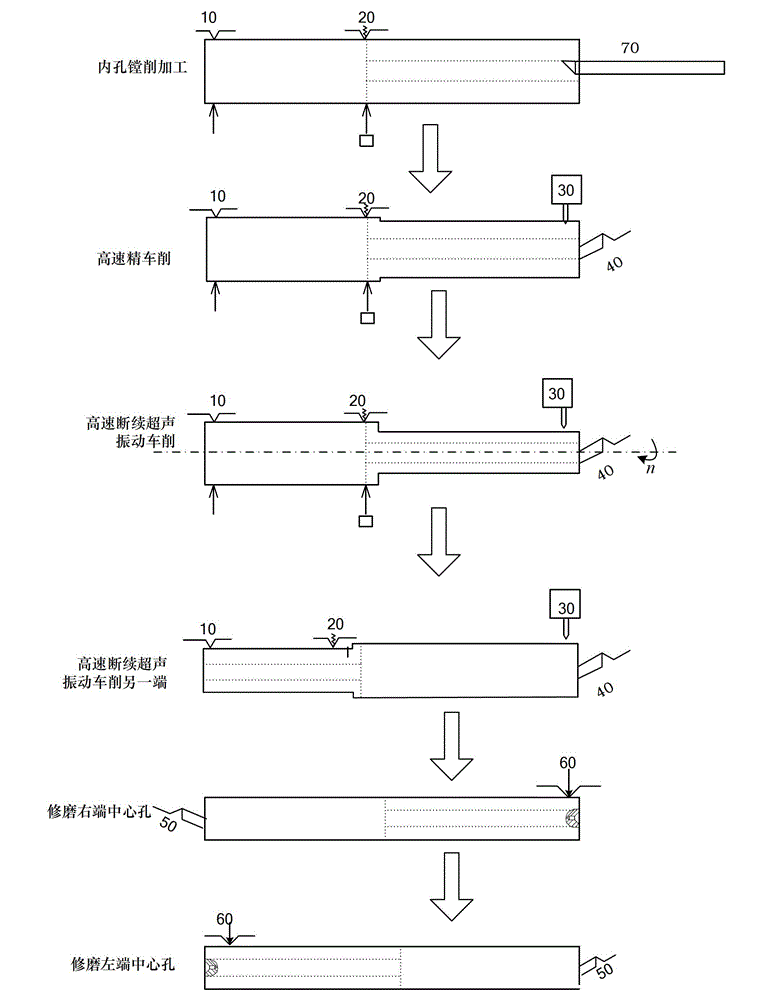

[0034] The present invention will be further described in detail below by taking the long-axis machining of a large-diameter deep hole as an example in conjunction with the accompanying drawings.

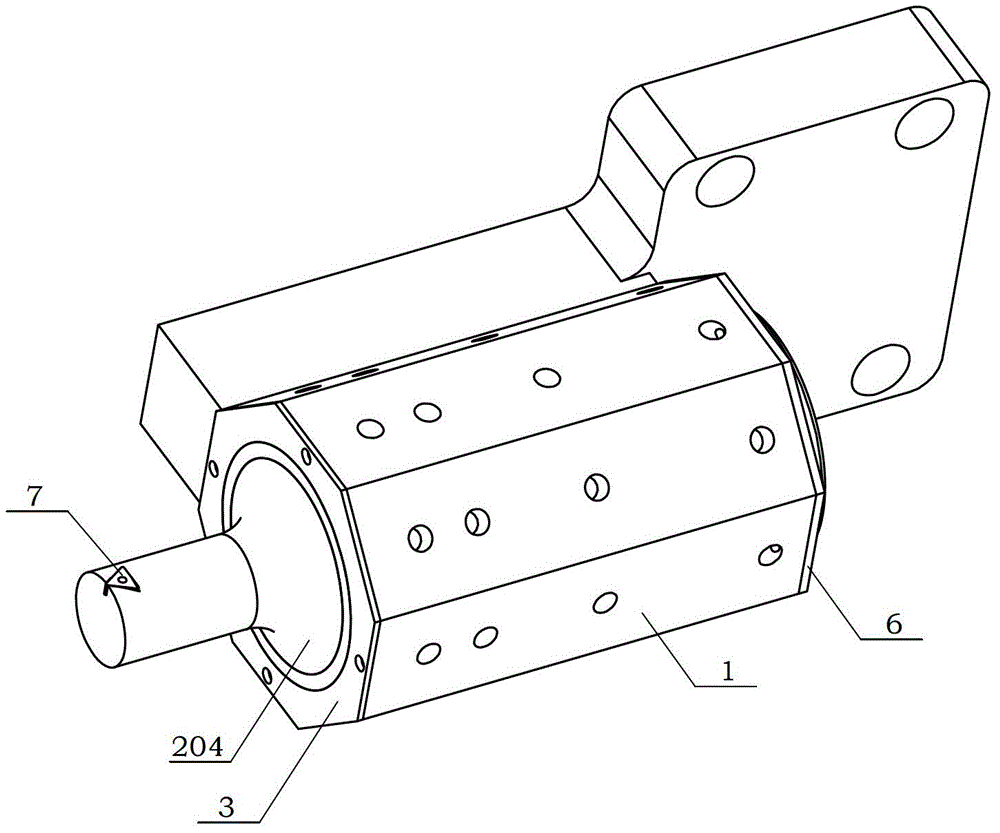

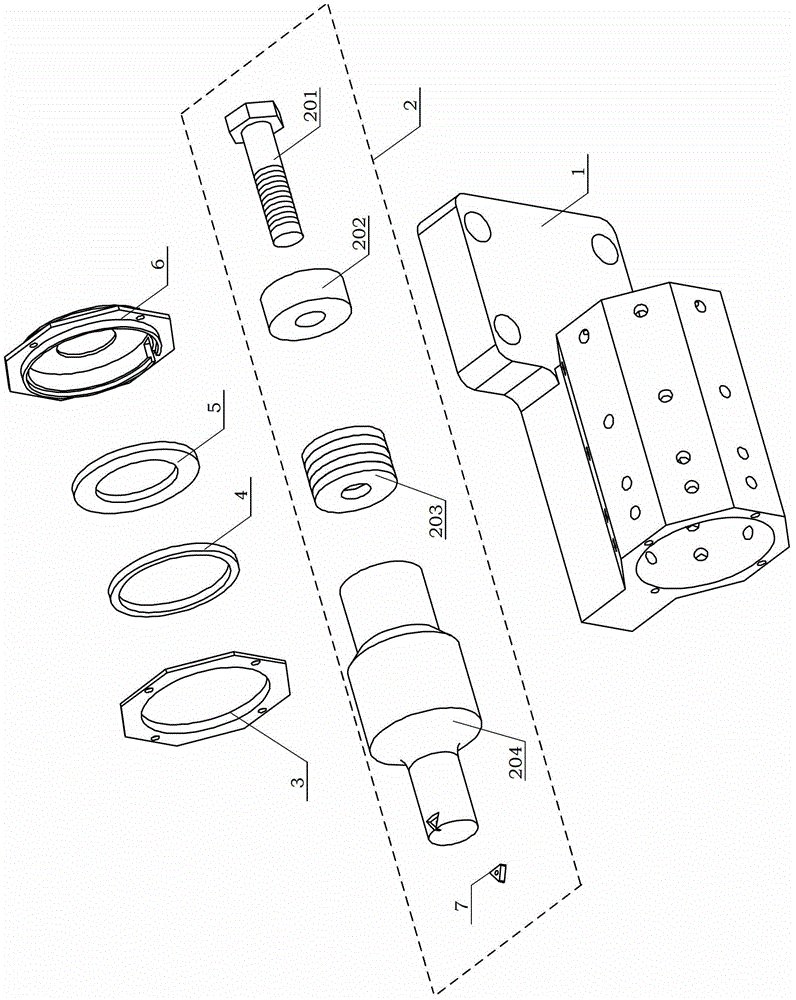

[0035] see figure 1 As shown, the present invention installs the matching ultrasonic longitudinal vibration cutting device 30 on the numerical control machining center, and then through the computer and the three-dimensional drawing software and control software installed in the computer, the parts (or workpieces) to be processed ) for controlled processing.

[0036] The present invention is a method for efficient and high-quality processing of large-diameter, deep-hole and long-axis weak stiffness parts based on ultrasonic longitudinal vibration. The processing method includes the steps of pre-processing preparation and part processing:

[0037] (1) Preparation before processing

[0038] Step 1-1: Digitize the part configuration, use 3D drawing software (such as CATIA / Autocad / Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com