Two-step method for vacuum annealing of iron-nickel soft magnetic alloy

An iron-nickel soft magnetic alloy and vacuum technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of substandard electromagnetic compatibility experiments, affecting the electromagnetic properties of products, and poor magnetic properties of alloys, etc. Deformation amount, improvement of electromagnetic performance, effect of ensuring assembly conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific content of the two-step vacuum annealing method for iron-nickel soft magnetic alloy will be further explained below in conjunction with the accompanying drawings, taking iron-nickel soft magnetic alloy 1J85 as an example.

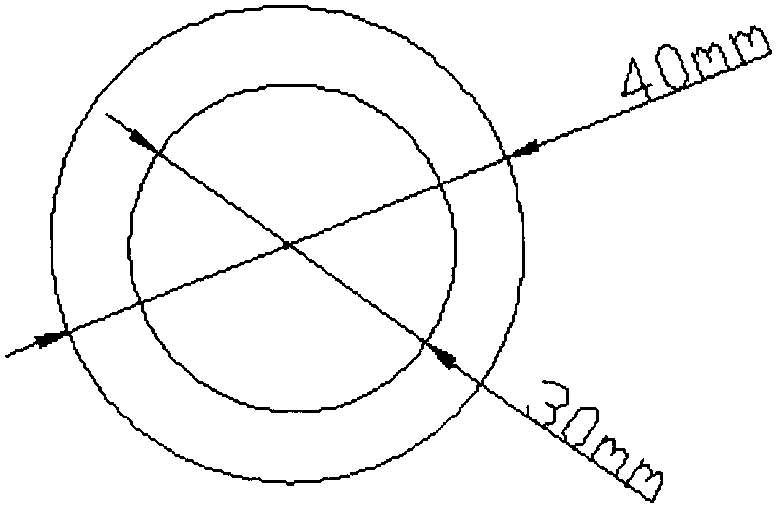

[0033] 1J85 refers to an iron-nickel soft magnetic alloy with a nickel content of 79.0% to 81.0%. The sample size used in this experiment is as follows figure 1 As shown, the thickness of the sample is: 0.8mm, the state is: cold-drawn strip, and the standard chemical composition of the sample is shown in Table 1:

[0034] Table 1 standard chemical composition

[0035] C

mn

Cu

Ni

Si

Mo

P.S.

Fe

0.03

0.30~0.60

≤0.20

79.0~81.0

0.15~0.30

4.80~5.20

0.02

margin

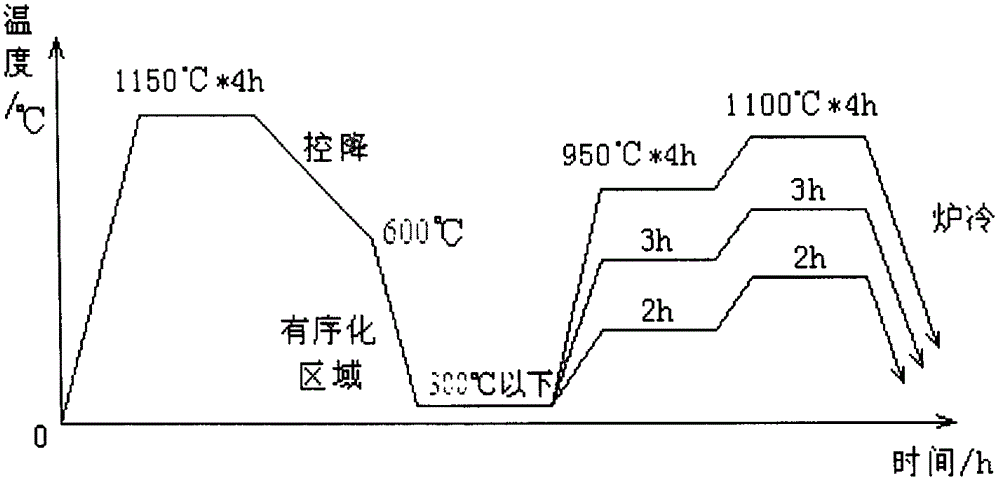

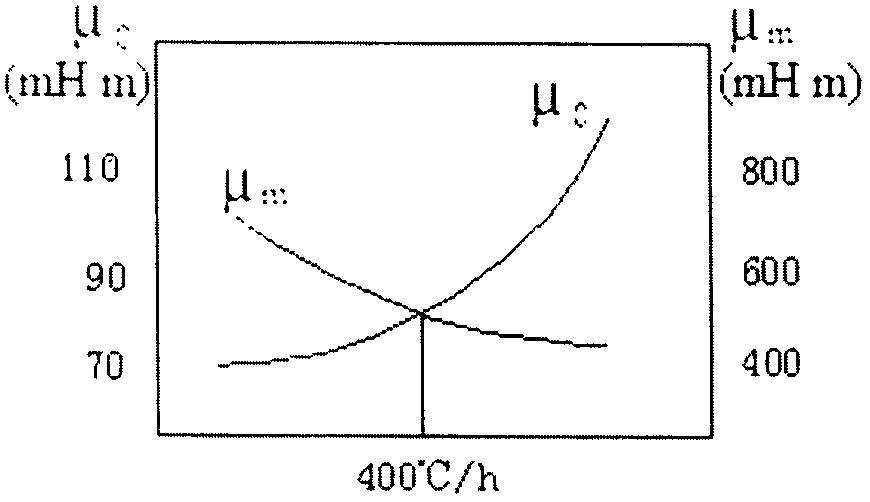

[0036] The heat treatment process has a great influence on the DC magnetic properties or low-frequency magnetic properties of 1J85 Fe-Ni soft magnetic alloy, but has little ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com