Manufacturing method for sealing head of high strength austenite nickel iron chrome alloy

A technology of nickel-iron-chromium alloy and production method, which is applied in the field of production of high-strength austenitic nickel-iron-chromium alloy head, can solve problems such as easy cracks, improve plasticity, eliminate defects, and improve intergranular resistance The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

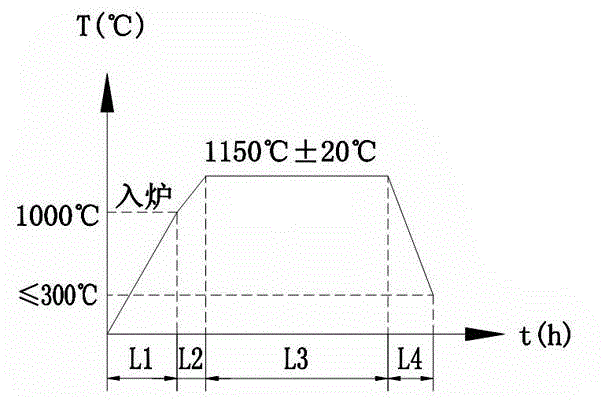

[0009] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. figure 1 L1 is heated by an empty furnace, L2 is heated with the furnace, L3 is kept warm in the furnace, and L4 is rapidly water-cooled. After the N08810 head has passed the re-inspection of the raw materials, it is cut according to the size required by the process. The head plates that need to be spliced are spliced according to the process requirements. Various parameters and testing requirements must meet the process requirements. The surface is 100% PT tested. According to JB / T4730-2005 Class I qualification inspection, after passing the non-destructive testing, the spliced welds shall be ground, and the weld reinforcement after grinding shall be 0.5~1mm to ensure that the welds are flush with the base metal after the head is pressed. After grinding, 100% PT inspection is performed on the weld again. According to JB / T4730-2005 level I qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com