Preparing method of thermoplastic elastomer environment-friendly basketball leather

A thermoplastic elastomer, basketball leather technology, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., can solve problems such as difficult to meet environmental protection requirements, human hazards, exhaust emissions, etc., and achieve a soft surface. , strong astringency, superior elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

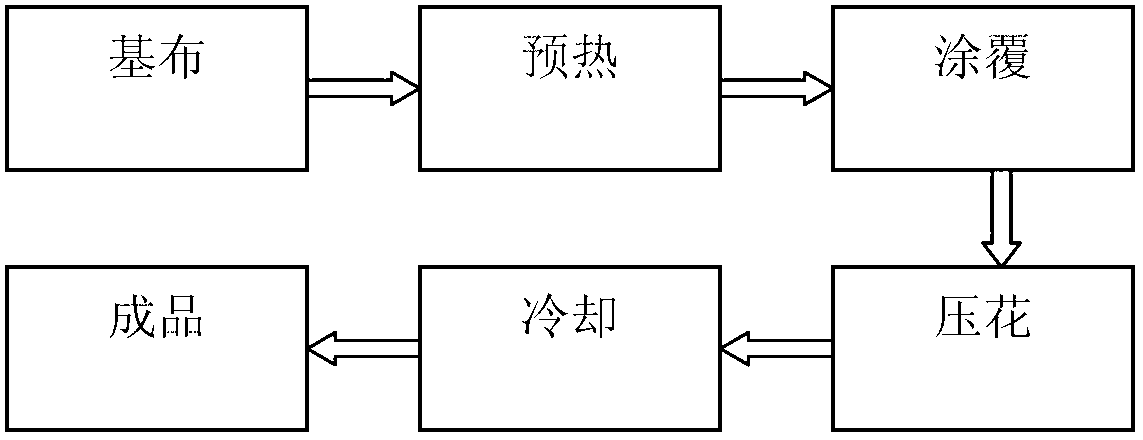

[0017] A kind of preparation method of thermoplastic elastomer environmental protection basketball leather, such as figure 1 As shown, follow the steps below:

[0018] Apply ethylene-vinyl acetate on one side of the polyester woven fabric at 100°C, and cool and set it under a pressure of 0.4Mpa;

[0019] 0.8 parts by weight of thermoplastic elastomer TPU and 0.3 parts by weight of silicone oil are melted at 170°C, and bonded to the above-mentioned treated woven fabric under a pressure of 0.6Mpa;

[0020] Mix 0.8 parts by weight of thermoplastic elastomer TPR with 0.2 parts by weight of AC foaming agent, heat and melt at 200 ° C to form a foam, and the foam is woven with the above-mentioned bonding treatment under a pressure of 0.4Mpa cloth for bonding;

[0021] Mix 0.8 parts by weight of thermoplastic elastomer TPE with 0.2 parts by weight of environmentally friendly masterbatch, melt at 250°C, and bond with the above-mentioned woven fabric treated with foam under a pressure...

Embodiment 2

[0024] A kind of preparation method of thermoplastic elastomer environmental protection basketball leather, such as figure 1 As shown, follow the steps below:

[0025] Coat the thermoplastic elastomer TPU on one side of the polyester woven fabric at 110°C, and cool and set it under a pressure of 0.2Mpa;

[0026] 0.6 parts by weight of styrene block polymer SBS and 0.1 parts by weight of polypropylene are melted at 150°C, and bonded to the above-mentioned treated woven fabric under a pressure of 0.2Mpa;

[0027] Mix 0.5 parts by weight of isoprene block copolymer SIS with 0.2 parts by weight of AC foaming agent, heat and melt at 250°C to form a foam, which is bonded to the above-mentioned warp under a pressure of 0.2Mpa The treated woven fabric is bonded;

[0028] Mix 0.7 parts by weight of thermoplastic elastomer TPE with 0.5 parts by weight of environmentally friendly toner, melt it at 150 ° C, and bond it to the above-mentioned woven fabric treated with foam under a pressu...

Embodiment 3

[0031] A kind of preparation method of thermoplastic elastomer environmental protection basketball leather, such as figure 1 As shown, follow the steps below:

[0032] Apply ethylene-vinyl acetate on one side of the non-woven fabric at 120°C, and cool and set it under a pressure of 0.3Mpa;

[0033] 0.7 parts by weight of thermoplastic vulcanizate TRV and 0.3 parts by weight of polypropylene are melted at 160°C, and bonded to the above-mentioned treated non-woven fabric under a pressure of 0.4Mpa;

[0034] Mix 0.9 parts by weight of thermoplastic rubber TPAE with 0.1 parts by weight of microsphere closed-cell foaming agent, heat and melt at 200°C to form a foam, and the foam is bonded to the above-mentioned bonded foam under a pressure of 0.5Mpa Bonding non-woven fabrics;

[0035] Mix 0.8 parts by weight of ethylene-butene copolymer POE with 0.2 parts by weight of environmentally friendly toner, melt it at 260 ° C, and bond it to the above-mentioned non-woven fabric treated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com