Modularized steel structure unit construction

A modular unit and steel structure technology, applied in building structure, building components, insulation, etc., can solve the problems that waste containers are difficult to meet the requirements of large-scale residential production, technology development is not thorough enough, labor cost increases, etc., to achieve simplicity Efficient assembly construction, flexible connection and combination forms, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

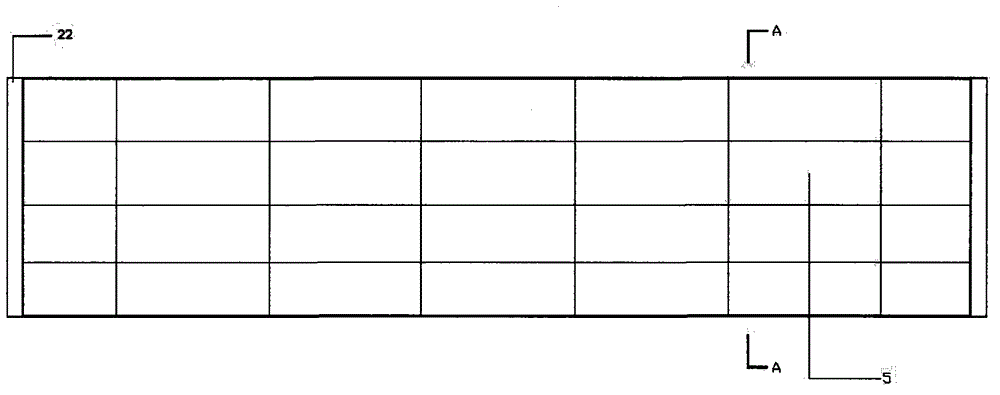

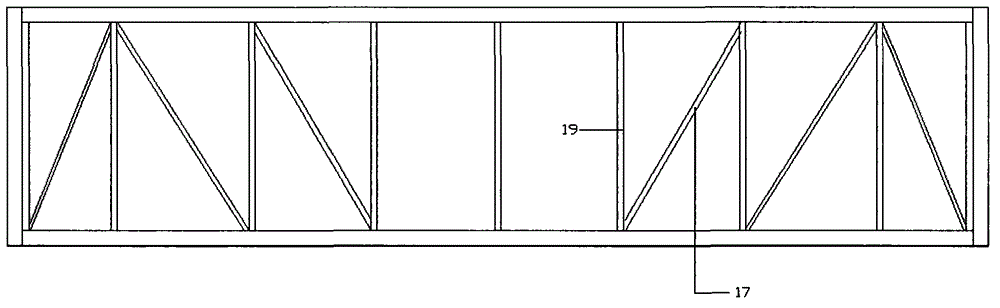

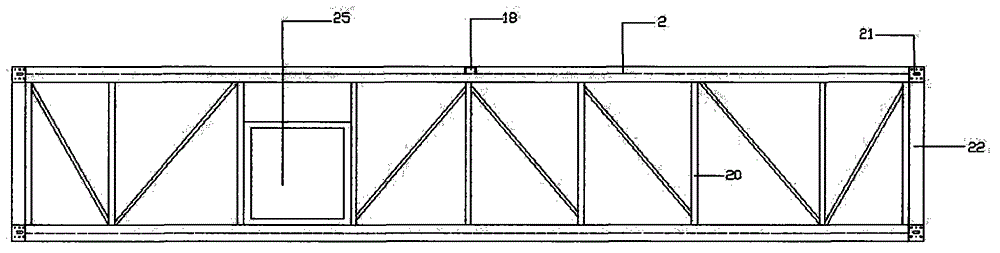

[0035] see Figure 1-6 As shown, a modular steel structure unit structure, each module unit is composed of a T-shaped steel keel 2 combined with angle steel, a steel keel 20 in the direction of heaven and earth, a vertical steel keel 19, and steel diagonal braces 24 to strengthen the overall strength to form a basic steel Framework. Frame-shaped steel wing plates 22 are welded at both ends of the basic steel structure frame. The four steel wing plate corners 21 of the frame-shaped steel wing plate 22 have hoisting holes 26 and installation holes 27 and are welded with L-shaped steel angles that also have hoisting holes 26 and installation holes 27. Part 16, the position, size and shape of the hoisting hole 26 are equal to the position, size and shape of the hoisting hole of the international standard container.

[0036] The GRC exterior wall panel 5 compounded with the exterior finish layer 4 containing steel mesh 7 is connected and fixed with the T-shaped steel keel 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com