After-treatment control unit for ammonia storage and ammonia supply in the form of exhaust pipe waste heat

A technology for ammonia storage, ammonia supply, and control unit, which is applied to the electrical control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., and can solve problems such as lack of clear instructions, inability of technicians to implement, and lack of dosing ratio. To achieve full practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

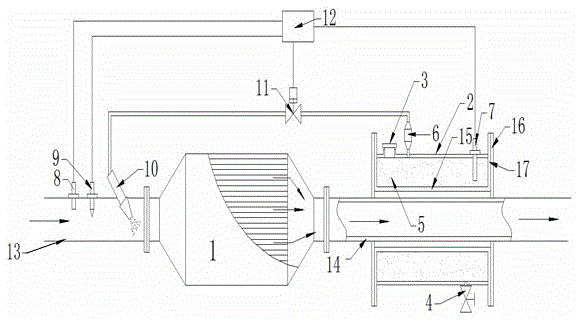

[0028] First weld the two ends of the inner wall tube 15 of the pressure tank with the two inner flanges 17 respectively, and then weld the two ends of the outer wall tube 2 of the pressure tank with the two inner flanges 17, so that The inner wall tube 15 of the pressure tank, the outer wall tube 2 of the pressure tank, and the inner flange 17 form an active material storage space; the feeding port 3 is welded on the outer wall tube 2 of the pressure tank; the spare pipe valve 4 is welded on the outer wall tube of the pressure tank 2. Connect the air filter 6 and the temperature sensor 7 to the outer wall of the pressure tank 2, and connect the reducing agent conduit 10 to the air filter 6 to complete the production of the pressure tank body;

[0029] Using 60 parts of industrial anhydrous calcium chloride, 2 parts of expanded graphite, 13 parts of deionized water, 10 parts of industrial ethanol and 15 parts of industrial ball clay, the total amount is 12kg, and the volume of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com