After-treatment control unit with electric heating and waste heat storage for ammonia supply

A technology for ammonia storage, ammonia supply, and control unit, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, engine components, etc. It can solve problems such as no clear instructions, technical personnel can’t implement, and no increase ratio, etc., to achieve full usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

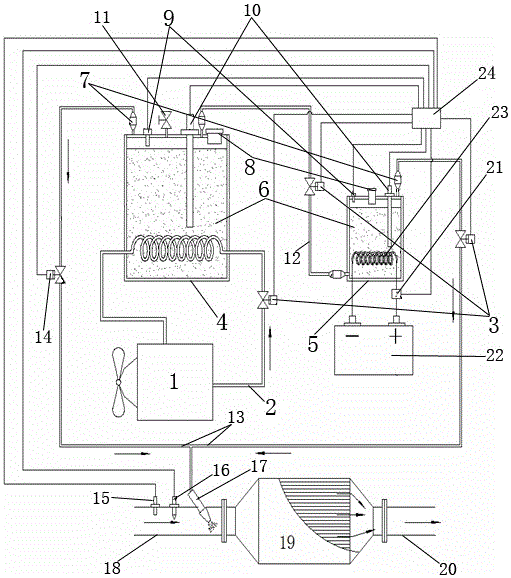

preparation example Construction

[0025] The preparation and filling method of the described solid ammonia storage material 6 are as follows: adopt 58 parts of industrial anhydrous magnesium chloride, 2 parts of expanded graphite, 15 parts of deionized water, 10 parts of industrial ethanol and 15 parts of industrial spherical clay. Mix and stir with a noodle mixer to form a wet powder. The mixing time is 5-15 minutes. Fill it into the main ammonia storage tank 4 and the auxiliary ammonia storage tank 5 through the feeding port 8. Vibrate the tank body by mechanical vibration for 5-10 minutes. Remove the air gap in it, and add the amount of material to 40% of the volume capacity of the tank; put the whole tank in a vacuum oven, start heating from room temperature 25°C under normal pressure, average 5°C / 10min, raise the temperature to 70°C, and heat When drying, the feeding port 8 is opened to discharge water vapor and alcohol vapor; keep at this temperature for 30 minutes, then start the vacuum pump at this temp...

Embodiment 1

[0029] The main ammonia storage tank 4 and the auxiliary ammonia storage tank 5 are pressure-resistant tanks made of stainless steel. The thickness of the tanks is 4-5mm, cylindrical, and a layer of nylon insulation is thermally sprayed inside the tanks.

[0030] The residual heat of the engine coolant is used to heat the active material so that it releases ammonia under appropriate conditions; however, in order to ensure that the exhaust temperature of the vehicle is low during cold start and the temperature of the engine coolant is not enough, the secondary ammonia storage tank 5 is used In the early stage of vehicle startup, the auxiliary ammonia storage tank 5 heated by the on-board storage battery 22 meets the ammonia supply requirements of the system, and this function is realized by the relay switch 21, storage battery 22 and electric heating wire 23; In practice, it can be set that the auxiliary ammonia storage tank 5 supplies ammonia for the first 20 minutes of vehicle...

Embodiment 2

[0038] The structural part of the system remains unchanged, but changes are made in the preparation method of the solid ammonia storage material 6. The specific process is as follows: 58 parts of industrial anhydrous magnesium chloride, 2 parts of expanded graphite, 15 parts of deionized water, 10 parts of industrial ethanol and industrial 15 parts of ball clay, 2.5kg of the mixture is prepared; use a mechanical dough mixer to mix evenly into a wet powder, gradually fill it into the auxiliary ammonia storage tank through the auxiliary feeding port, and use the method of mechanical vibration to shake the pressure-resistant tank during the process 5~10min; put the whole tank into a vacuum oven, start heating at room temperature at 25°C under normal pressure, average 5°C / 10min, and heat up to 70°C. When heating and drying, the main feeding port is open; keep at this temperature for 30min , and then start the vacuum pump at this temperature, gradually evacuate, three times to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com