Preparation and filling method of solid ammonia storage material for aftertreatment control unit

A filling method and technology of a control unit, which are applied in the electrical control, exhaust treatment, mechanical equipment, etc. of the exhaust gas treatment device, can solve the problems of no clear description, no increase ratio, and inability for technicians to implement, and achieve full practicality. Sex, long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

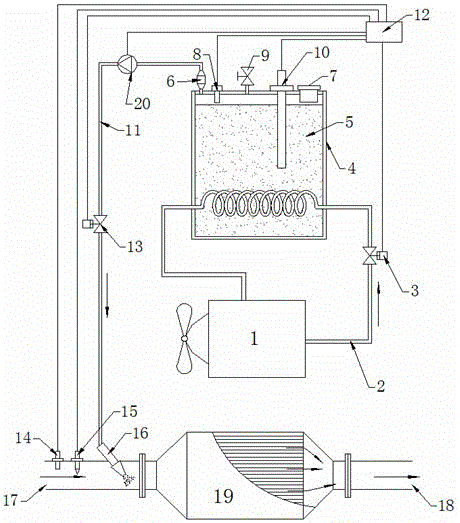

preparation example Construction

[0027] The preparation and filling method of the solid ammonia storage material 5 is as follows: 58 parts by weight of industrial anhydrous magnesium chloride, 2 parts of expanded graphite, 15 parts of deionized water, 10 parts of industrial ethanol and 15 parts of industrial ball clay are used. The above-mentioned materials are mixed evenly into a wet powder by a mechanical mixer. The mixing time is 5~15min. The mixture is filled into the pressure tank 4 through the feeding port 7 on the pressure tank 4, and the mechanical vibration method is used to shake the Press the tank for 5~10min, remove the air gap, and add the material to 40% of the volume of the tank; put the whole tank in a vacuum oven, start heating from room temperature 25℃ under normal pressure, average 5℃ / 10min, increase the temperature When it reaches 70°C, the feed port 7 is opened to discharge water vapor and alcohol vapor, keep at 70°C for 30 minutes, and then start the vacuum pump at this temperature to grad...

Embodiment 1

[0030] Choose a SUS304 plate with a thickness of 4mm and first weld it into a stainless steel barrel with an inner diameter of 300mm and a height of 330mm. The cooling liquid circulation pipeline and the coil are welded in sequence, and the bottom welding is completed. The inner wall of the barrel is thermally sprayed with nylon powder once, pay attention to heating The coil tube is not sprayed with nylon; the welding of the upper cover is completed, and the feeding port 7, pressure sensor 8, spare pipe valve 9, temperature sensor 10, reducing gas delivery pipe 11 and filter 6 are completed on the upper cover. Connection of relevant parts of pressure tank 4; pressure leak test to ensure that the sealing and welding quality meet the requirements;

[0031] 58 parts of industrial anhydrous magnesium chloride, 2 parts of expanded graphite, 15 parts of deionized water, 10 parts of industrial ethanol and 15 parts of industrial ball clay are used. The above-mentioned materials are mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com