Method for quickly measuring ultra-low carbon and ultra-low sulfur in steel by atomic emission spectrometry

An atomic emission spectrometry and rapid determination technology, which is applied in the field of rapid determination of ultra-low carbon and ultra-low sulfur in steel by atomic emission spectrometry, can solve the problems of large influence of sample preparation, harsh analysis conditions, limitation of spectral standard samples, etc. The effect of high accuracy, fast analysis speed and low analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

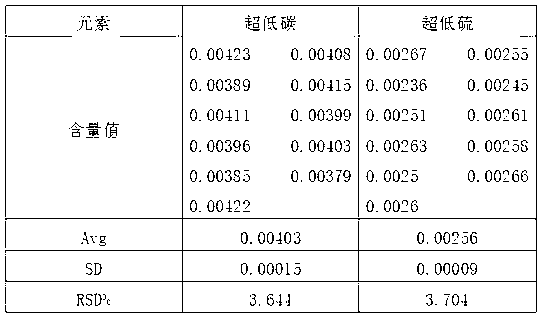

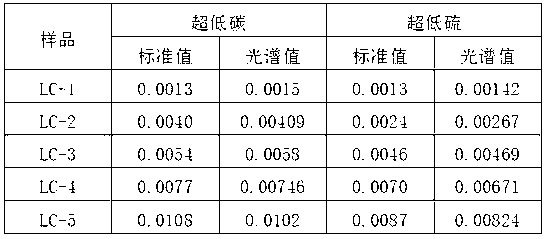

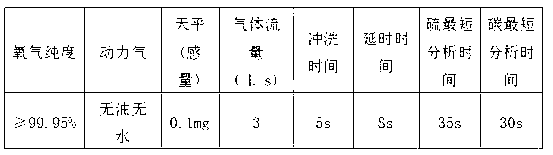

[0013] The atomic emission spectrometry method for quickly determining ultra-low carbon and ultra-low sulfur in steel uses an atomic emission spectrometer combined with an infrared carbon-sulfur instrument for determination. After systematically studying the two methods, this method solves the problem of accurate and rapid determination of ultra-low carbon and ultra-low sulfur in steel by atomic emission spectrometer in front of the steelmaking furnace through self-selection, preparation, and value-fixed spectral sample control methods, and rejects infrared The carbon-sulfur meter has a long analysis period and a great influence on the sample preparation process, which is not suitable for the disadvantages of rapid and accurate determination before the steelmaking furnace. Combining the advantages of both methods, it has been proved that the method is accurate and reliable, and can meet the requirements of analytical technology and production technology. The first is the selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com