Method for preparing assembly type polymer micro fluidic chip equipped with integrated pneumatic micro valve

A microfluidic chip and assembled technology, which is applied to the analysis of materials, instruments, etc., can solve the problems of cumbersome and time-consuming operation process, affecting the stability of the analysis system, the reliability of the analysis results, and leakage, etc., and achieves a simple and reliable sealing process. Good fluid handling performance, the effect of free assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

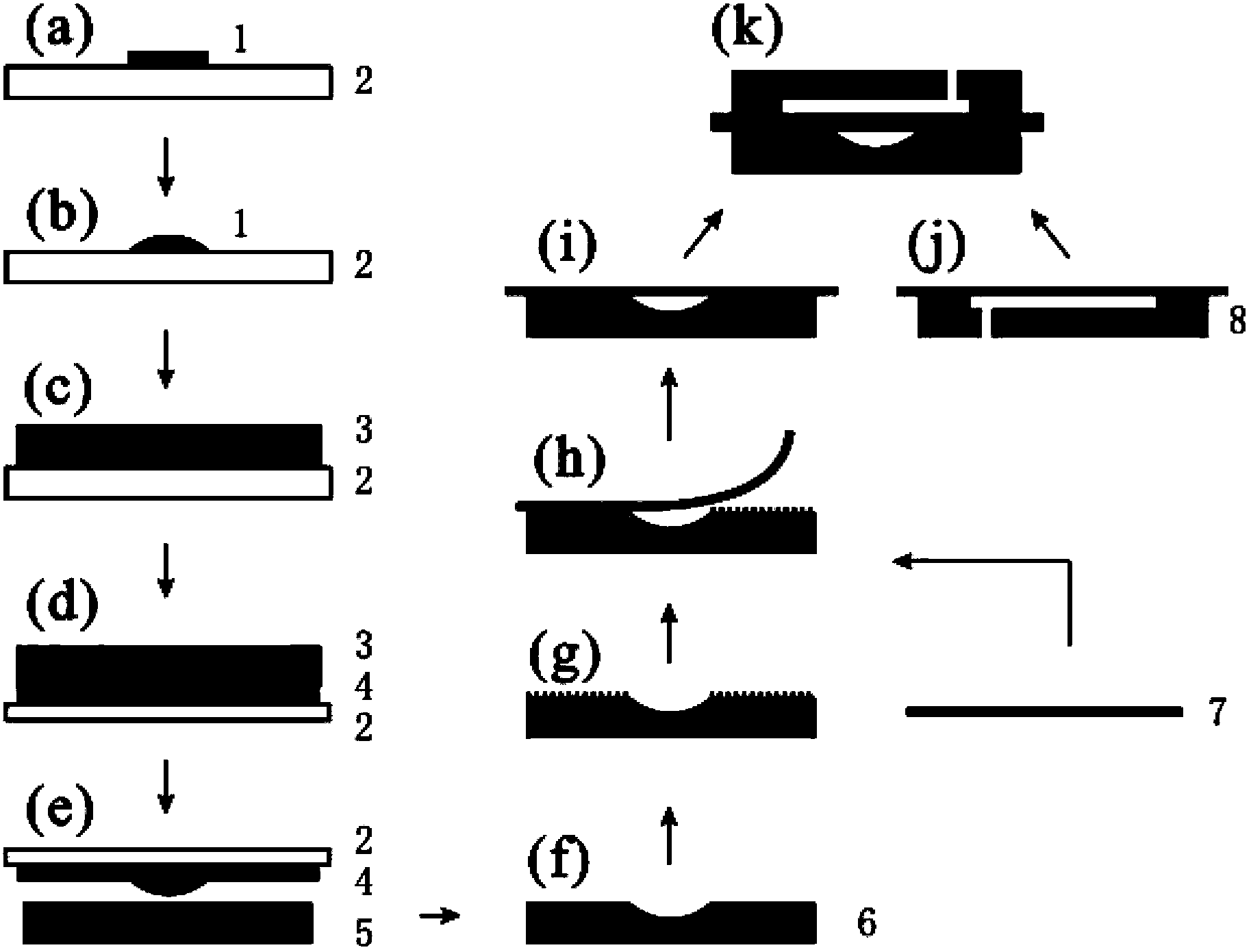

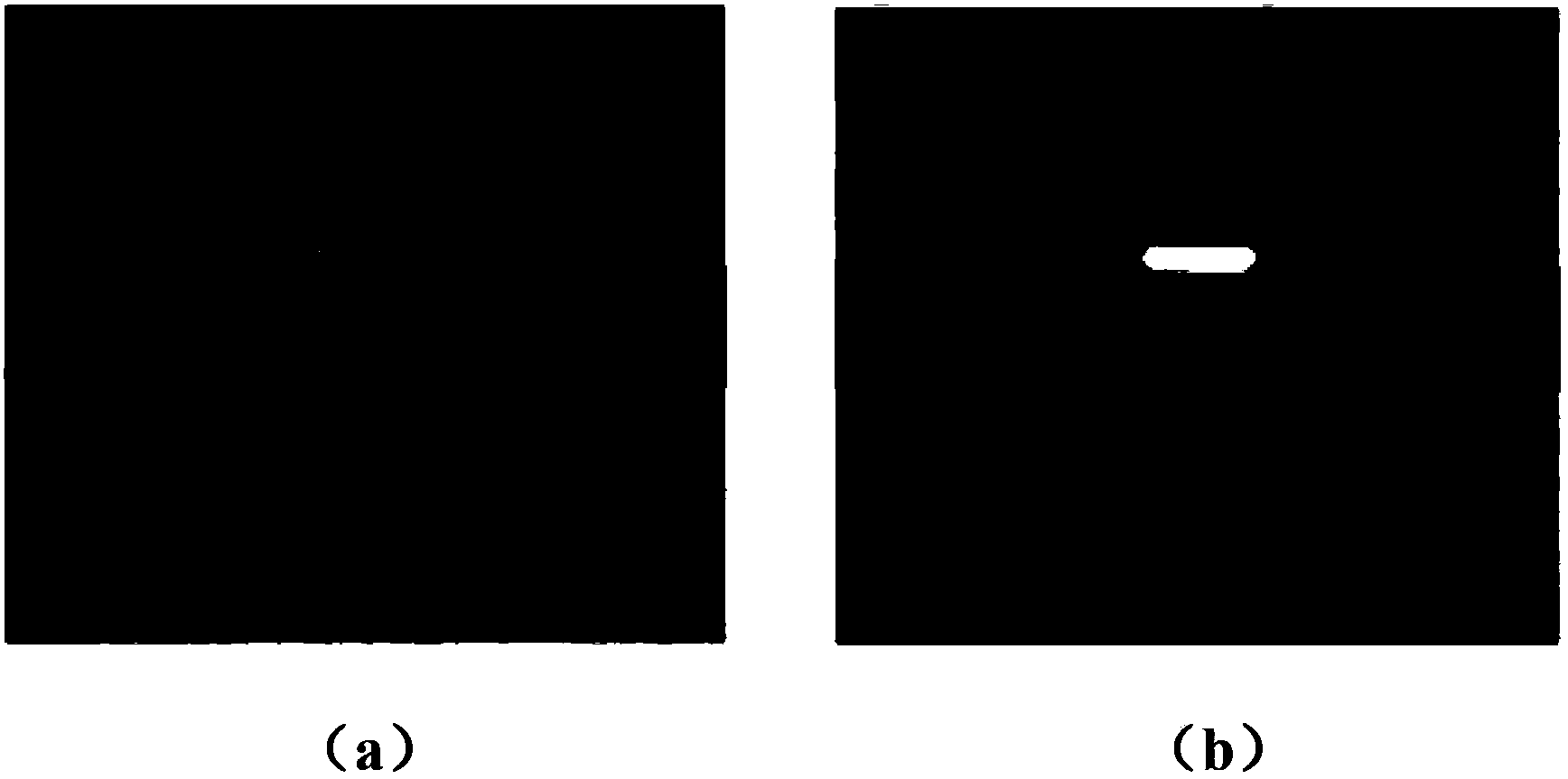

[0030] The invention is a method for preparing an assembleable plastic chip with a double-layer elastic membrane pneumatic microvalve. The microchannels were prepared on the plastic substrate by hot pressing method, and the irreversible sealing between the plastic substrate and the PDMS elastic film was realized through three steps of ultraviolet light surface activation, silanization, and plasma surface treatment, and the control half-chip and the control half-chip were prepared respectively. Liquid circuit half-chip; with the help of the natural adhesive force of PDMS film, the liquid circuit half-chip and the control half-chip are reversibly sealed to form a four-layer structure with plastic gas circuit control substrate-PDMS···PDMS-plastic liquid circuit substrate Plastic full chip.

[0031] figure 1 It is a flow chart of the fabrication of a plastic full-chip integrated with a double-layer elastic film pneumatic microvalve.

[0032] The plastic material in the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com