Integrated differential quartz vibrating beam accelerometer on basis of folding beam structure

A technology of accelerometer and folded beam, which is applied in the field of micro-inertial sensing, can solve the problems of lowering the threshold and small elastic stiffness, and achieve the effects of lowering the threshold, increasing the volume, and reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

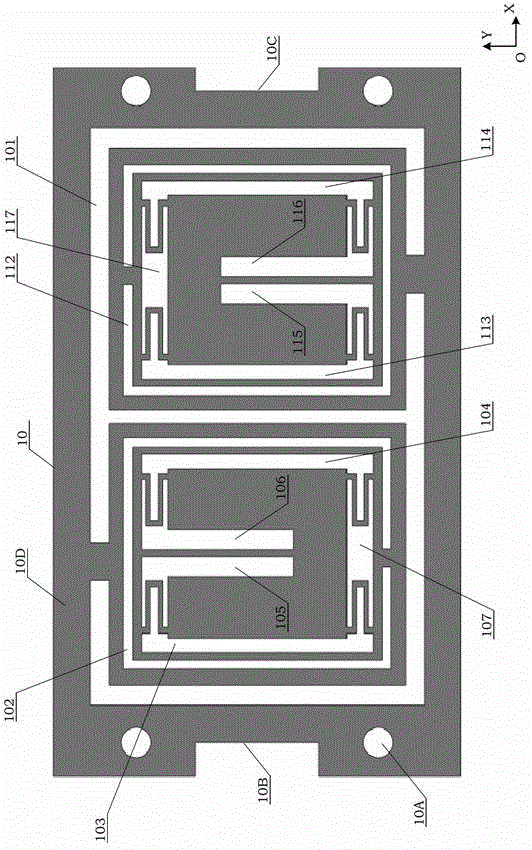

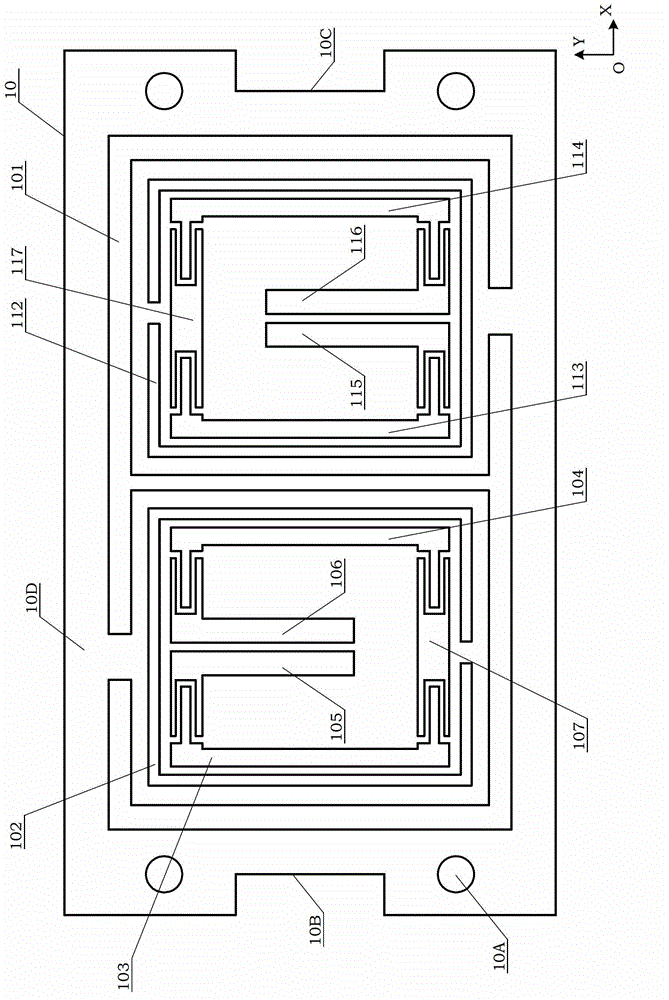

[0025] see figure 1 , Figure 1A As shown, an integrated differential quartz vibrating beam accelerometer based on a folded beam structure of the present invention is obtained by removing a configuration cavity on a quartz substrate 10 by using a conventional wet etching process. The configuration cavity includes a first cavity 101, a second cavity 102, a third cavity 103, a fourth cavity 104, a fifth cavity 105, a sixth cavity 106, a seventh cavity 107, The eighth cavity 112, the ninth cavity 113, the tenth cavity 114, the eleventh cavity 115, the twelfth cavity 116, the thirteenth cavity 117; in order to realize the accelerometer of the present invention design and other For the installation of the platform, the outside of the first cavity 101 is called the installation frame 10D, and there are installation holes 10A on the four corners of the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com