Atomic force microscope imaging method and device of microscopic monitoring type selectable region

A technology of atomic force microscopy and atomic force microscopy, which is applied in measuring devices, scanning probe microscopy, instruments, etc., can solve the problems of randomness and blindness, limitations of microscopic imaging performance, scanning imaging, etc., and achieve improved Operational performance and scanning imaging quality, real-time monitoring and area selection, and the effect of improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

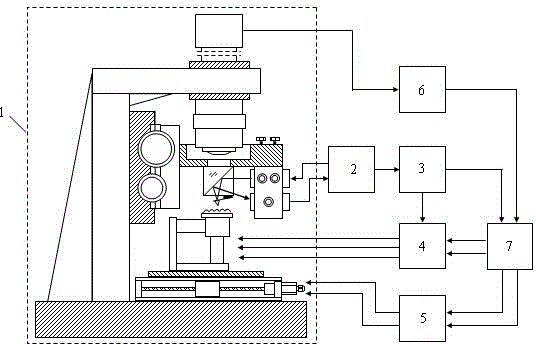

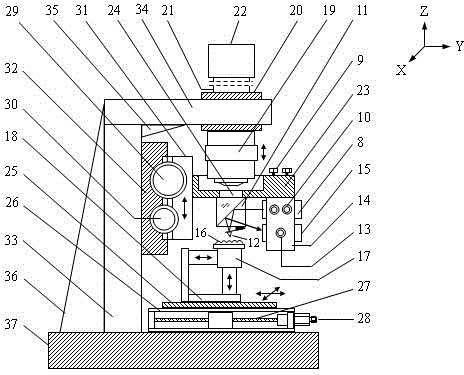

[0013] Micro-monitoring type optional area AFM imaging method: using the method of combining optical micro-monitoring with AFM micro-imaging, and combining the AFM scanner with a two-dimensional stepping The transflective prism, optical microscope objective lens and CCD are used for real-time microscopic monitoring of the atomic force microscope scanning area of the sample; at the same time, the adjustment and alignment process of the laser beam on the atomic force microscope microprobe is monitored, so as to effectively Improve the operational performance and scanning imaging quality of the atomic force microscope; in addition, monitor the micro-nano approach process between the sample and the atomic force microscope microprobe, thereby improving the efficiency and reliability of the micro-nano approach operation; introduce a two-dimensional stepping and micro-moving stage, Under microscopic monitoring, select the area of the sample surface of interest, and cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com