AGV (Automatic Guided Vehicle) control system based on bus control mode

A bus control and control system technology, applied in the field of mobile robots, can solve the problems of failure to meet the requirements of practical applications, difficulty in free scalability, difficulty in high-precision peripherals, etc., and achieve small electromechanical time constants, low power consumption, The effect of accurate positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

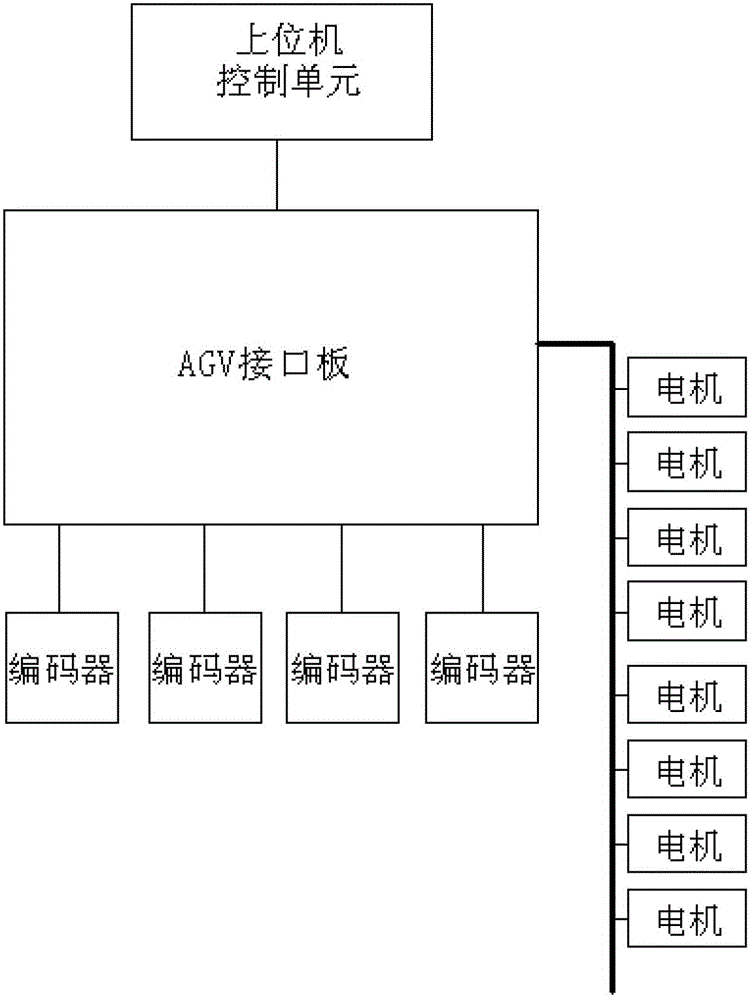

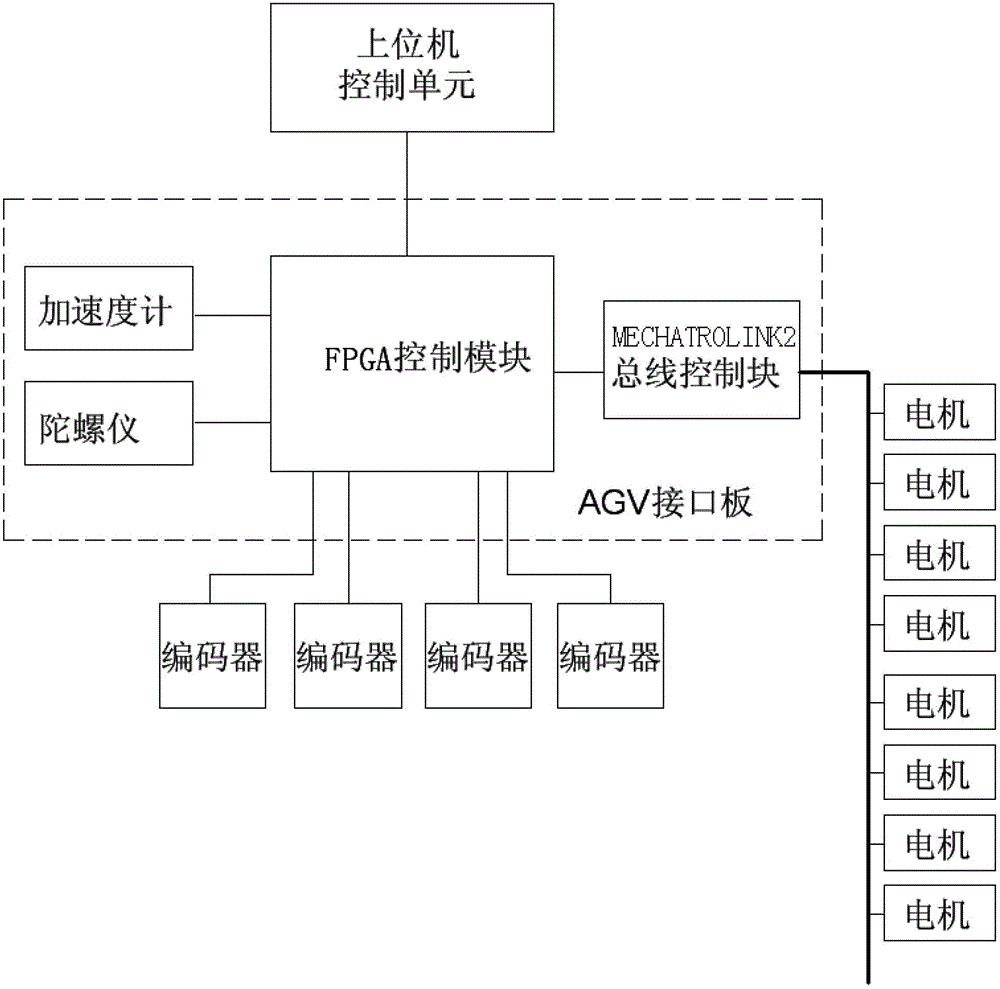

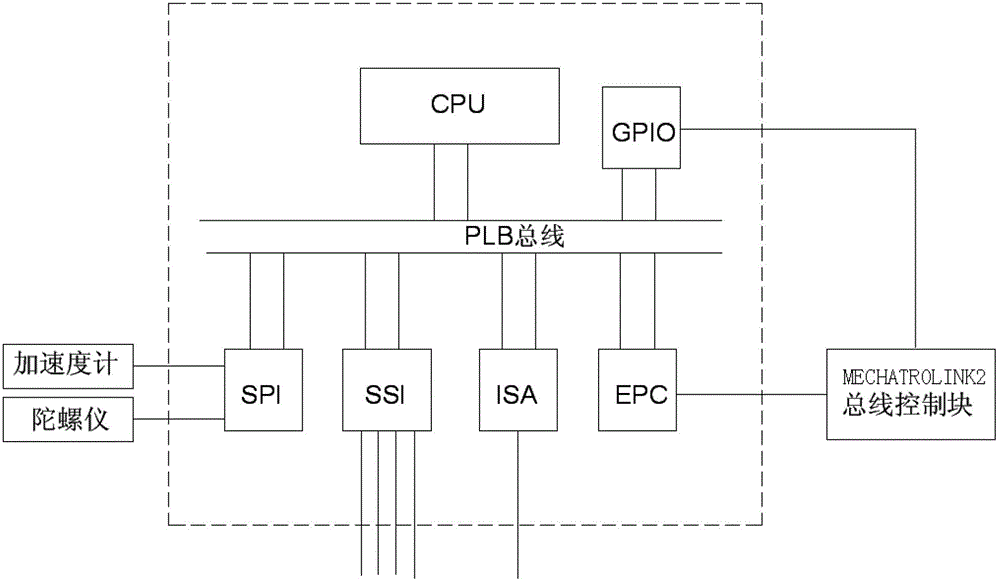

[0020] An AGV control system based on bus control mode, such as figure 1 , including the upper computer control unit, AGV interface board, servo motor and absolute encoder. The AGV interface board is connected to a group of servo motors that drive the AGV wheels through the MECHATROLINK2 bus to collect the working status of each servo motor. The AGV interface board is connected to the gyroscope and accelerometer to collect the gyroscope deviation signal (angular rate) and the acceleration signal of the accelerometer; the AGV interface board is connected with a group of absolute encoders installed on the axle to collect absolute encoding values. The AGV interface board performs real-time data interaction with the upper computer control unit through Ethernet, and within 1 millisecond control cycle, according to the upper computer control command, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com