Implementation method of formal semantic integration framework for model transformation of numerical control system

A technology of numerical control system and model conversion, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

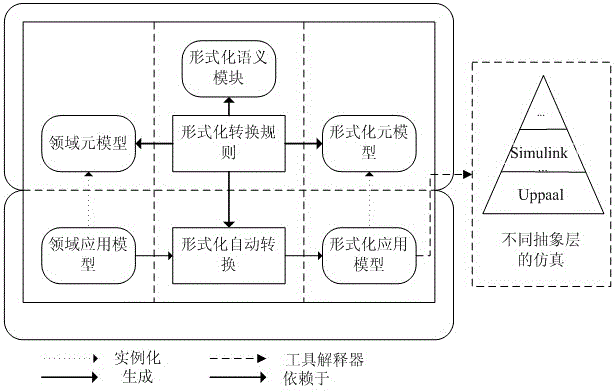

[0031] Example: Taking the construction of the semantic module composed of time automaton and time multi-task MOC of the numerical control system as an example, the implementation process of the formal semantic integration framework of the numerical control system is illustrated.

[0032] 1) Two MOCs, timed automata and timed multitasking, are used to describe the time-related state transition of the system and the execution behavior of real-time tasks. CNC system is a typical real-time multi-task system, so this semantic module is suitable for describing the task implementation behavior of CNC system, so as to pass the real-time verification and ensure the real-time performance of CNC system. Timed automata are used to represent time-constrained state transitions in real-time systems by using a finite number of truth-valued clock variables to represent time-constrained state transition graphs. Time multitasking describes the time multitasking semantic behavior of the CNC syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com