Returning platform for double-layer bidirectional railway-track-compatible green bus systems

A technology of public transportation system and track, which is applied in the field of double-layer two-way track compatible green bus system return platform, which can solve the problems of affecting the smooth flow of vehicles, wasting manpower, financial resources, material resources, and unsatisfactory actual results, and achieves cost performance and feasibility Significant safety, saving space for carriage return, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

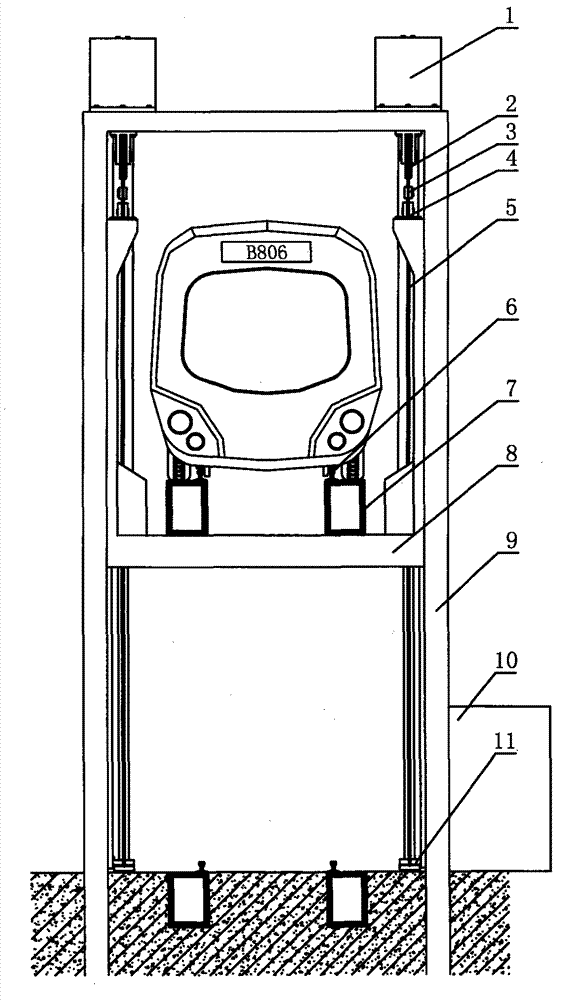

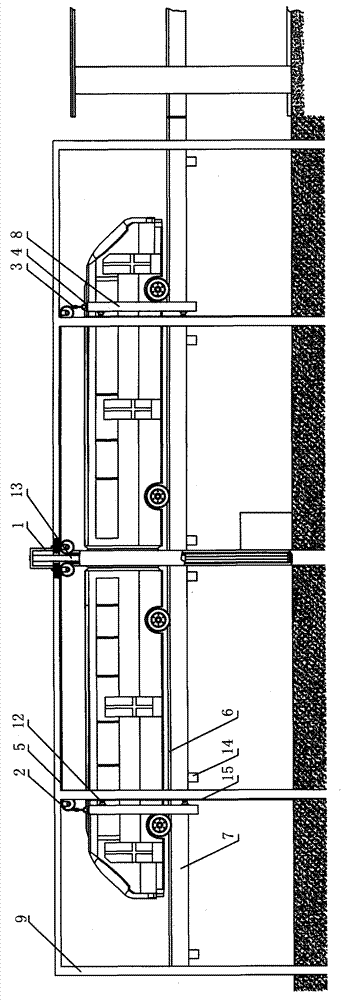

[0015] Operation part of track section: in figure 1 , 2 Among them, the car return platform is provided with an elevated beam pier 9, which is in the shape of "冂", and is connected to form a frame-like whole. There are oil cylinder bases 1 respectively, a pumping station 10 is arranged on the ground next to the oil cylinder 13, two lifting frames 8 are "U" shaped, and there are two rail wheels 12 on the lifting frame 8, which are connected with the elevated beam pier 9. The guide rail 15 coincides with the guide rail 15. There is a set of rails 7 inside. The guide rail 6 is arranged on the inner side of the top of the rail 7. The lifting frame 8 supports the rail 7 like a hoop. 5. One end is connected to the bottom end of the oil cylinder 13 through the steel rope splint 11 of the oil cylinder, and the other end is connected to the lifting lug 4 by bypassing the pulley 2. A steel rope splint 3 is provided at the connection between the steel rope 5 and the lifting lug 4, and a...

Embodiment 2

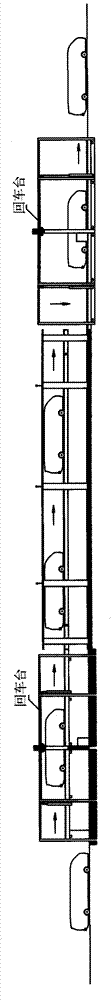

[0018] The difference between this embodiment and Embodiment 1 is that: the vehicle of this embodiment implements full-line operation, see image 3 , 4 , in the figure, the vehicle is a single-section single-cab, the vehicle running route is suburban-urban-suburban, and the mode of operation is highway-track-highway. Bus lines in urban areas are generally busy and should be rail sections. Bus extension lines beyond urban areas have relatively less passenger flow and should be highway sections. The operation mode of the vehicles on the highway sections is the same as that of ordinary trams. During the track section, the vehicle needs to enter the return platform first. When the vehicle is safely on the track, its operation mode is the same as that of the rail operating vehicle in Embodiment 1. The difference is that when the track operating vehicle reaches the end of the track, it can pass through the return platform. Lifting "does not turn around" and changes direction, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com