Rack and pinion steering device

A steering gear and pinion technology, applied in steering gears, steering mechanisms, mechanical steering gears, etc., can solve problems such as thorny operation noise risks, and achieve the effect of simplifying the entire structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

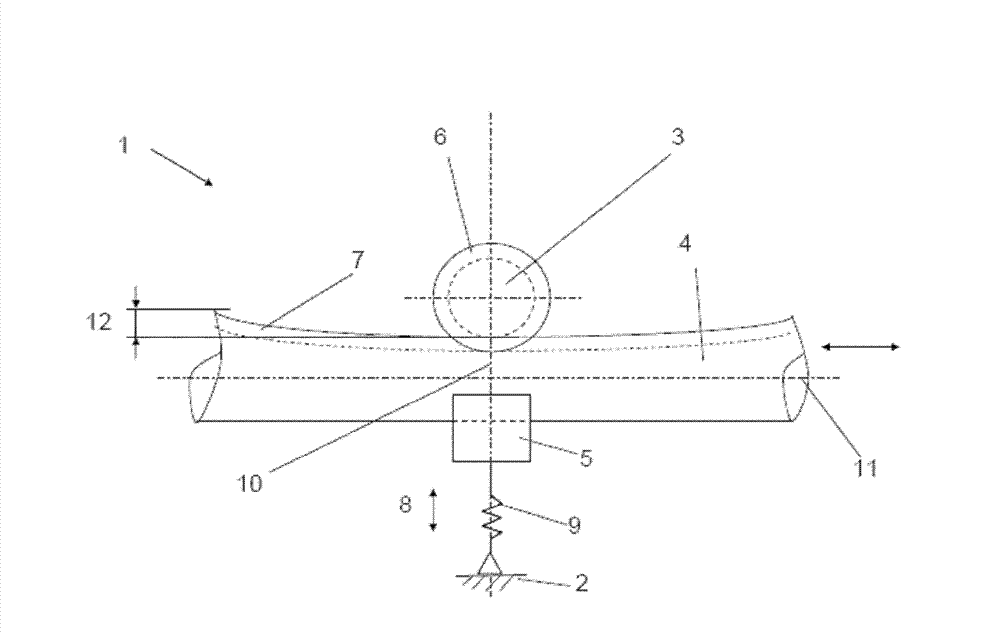

[0041] figure 1 A schematic partial plan view of an embodiment of a rack and pinion steering device 1 according to the invention is shown. Rack and pinion steering 1 comprises a drive pinion 3 rotatably mounted in a steering housing 2, a rack 4 axially movable in the steering housing 2 and a pressure piece 5. The rotatable mounting of the drive pinion 3, and the axially movable mounting of the rack 4 and the pressure piece 5 are done in a conventional manner and are therefore not in figure 1 displayed in detail. Steering gear housing 2 similarly only in figure 1 Schematic indication in.

[0042] In the illustrated embodiment, figure 1 The steering device 1 shown in is part of a steering device (not shown in the figure) of a vehicle, in particular a motor vehicle. For this purpose, the drive pinion 3 is connected for co-rotation with the steering gear end of a steering column which in turn is connected at its other end to a steering wheel by means of which the driver of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com