Plant landscape-type sewage ecological treatment technology

A technology for ecological treatment and sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large area of treatment system, influence on popularization and application, restrictions, etc. Achieve the effects of saving operation and management costs, improving regeneration capacity, and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

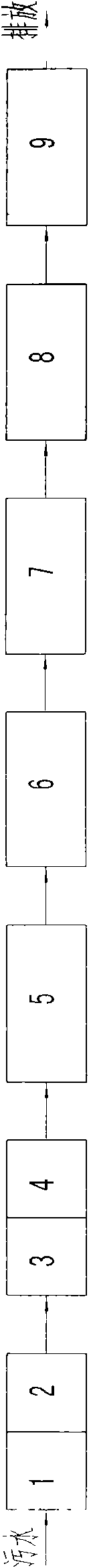

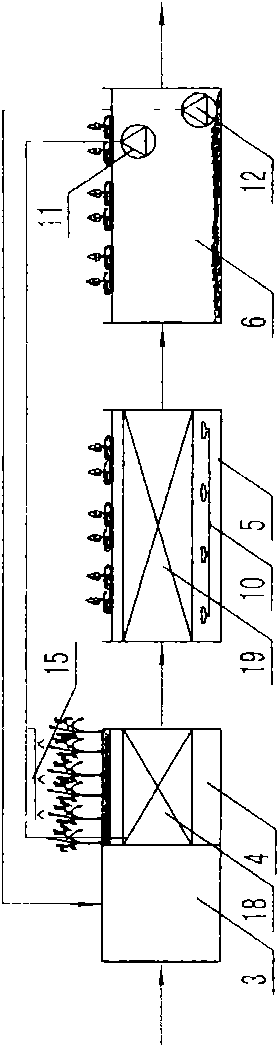

[0024] Refer to attached figure 1 , 2 6. Treatment object: domestic sewage in a certain village. Processing capacity: 15tph. Sewage treatment process: lifting pump room, grid well (1), grit chamber (2), pre-sedimentation tank (3), submerged flow anaerobic tank (4), surface flow microdynamic nitrification tank (5), sedimentation Stable pond (6), surface flow ecological ditch (7), subsurface flow ecological green space (8) and ecological release pond (9). Drainage into the river. Among them, the design parameters are pre-sedimentation tank (3) HRT1h, subsurface flow anaerobic tank (4) HRT24h, surface flow microdynamic nitrification tank (5) HRT4h, sedimentation stabilization pond (6) HRT3h. The pump (11) is 15tph, and 60% of the effluent enters the submerged anaerobic tank (4), and the rest is sprayed to the plants. Pump (12) 10tph, regular operation, 0.5h at intervals of 6h. The pump (16) runs regularly, and backwashes for 0.4h at intervals of 8h. System treatment effec...

Embodiment 2

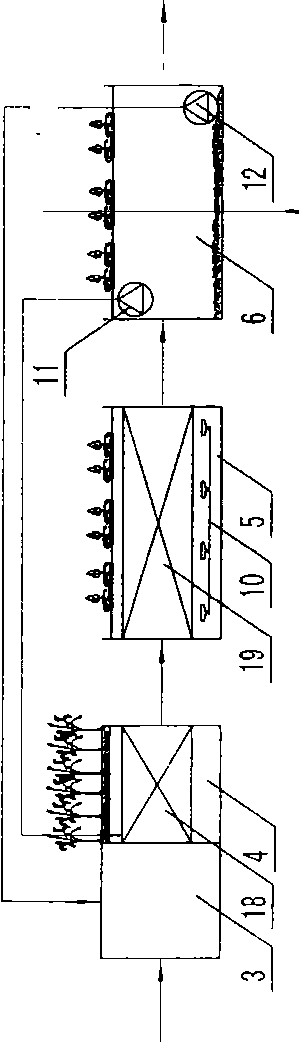

[0026] Refer to attached figure 1 , 3 6. Treatment object: domestic sewage in a certain town. Design capacity: 110tph. Sewage treatment process: lifting pump room, grid well (1), grit chamber (2), pre-sedimentation tank (3), submerged flow anaerobic tank (4), surface flow microdynamic nitrification tank (5), sedimentation Stable pond (6), surface flow ecological ditch (7), subsurface flow ecological green space (8) and ecological release pond (9). Drainage into the river. Among them, the design parameters are pre-sedimentation tank (3) HRT1.5h, subsurface flow anaerobic tank (4) HRT20h, surface flow microdynamic nitrification tank (5) HRT5h, sedimentation stabilization pond (6) HRT2.8h. The pump (11) operates at 120tph at regular intervals of 0.5h for 1h. The pump (12) runs regularly at 50tph, and runs for 0.4h every 5h. The pump (16) runs regularly, backwashing at intervals of 8h and 0.4h, and inflating during backwashing. System treatment effect: the COD removal rate...

Embodiment 3

[0028] Refer to attached figure 1 , 46. Treatment object: Sewage from a food industrial park (food waste water 50%). Design capacity: 100tph. Sewage treatment process: sewage regulating tank, lifting pump room, grid well (1), grit chamber (2), pre-sedimentation tank (3), subsurface flow anaerobic tank (4), surface flow microdynamic nitrification tank ( 5), sedimentation stabilization pond (6), surface flow ecological ditch (7), subsurface flow ecological green space (8) and ecological release pond (9). Drainage into the river. Among them, the design parameters are pre-sedimentation tank (3) HRT4h, submerged flow anaerobic tank (4) HRT36h, surface flow microdynamic nitrification tank (5) HRT10h, sedimentation stabilization pond (6) HRT4h. The pump (11) runs continuously at 200tph. The pump (12) runs regularly at 50tph, and runs for 0.5h every 2h. The pump (16) runs regularly, and backwashes for 0.4 hours at intervals of 6 hours, and inflates during backwashing. System t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com