Organic or inorganic fiberglass for enhancement, and composition thereof

A composition and glass fiber technology, applied in the field of glass fiber material and glass fiber composition for reinforcement, can solve the problems of high price and increase the production cost of glass fiber, achieve improved corrosion resistance and high temperature resistance, good fiber formation Sexual, cost-saving effect

Inactive Publication Date: 2012-10-17

CHONGQING POLYCOMP INT

View PDF14 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The glass fiber significantly reduces the B 2 o 3 and F 2 content, but at the same time in order to improve the fiber-forming performance, the formula also added expensive CeO 2 , SrO and MnO 2 , which will obviously greatly increase the production cost of glass fiber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

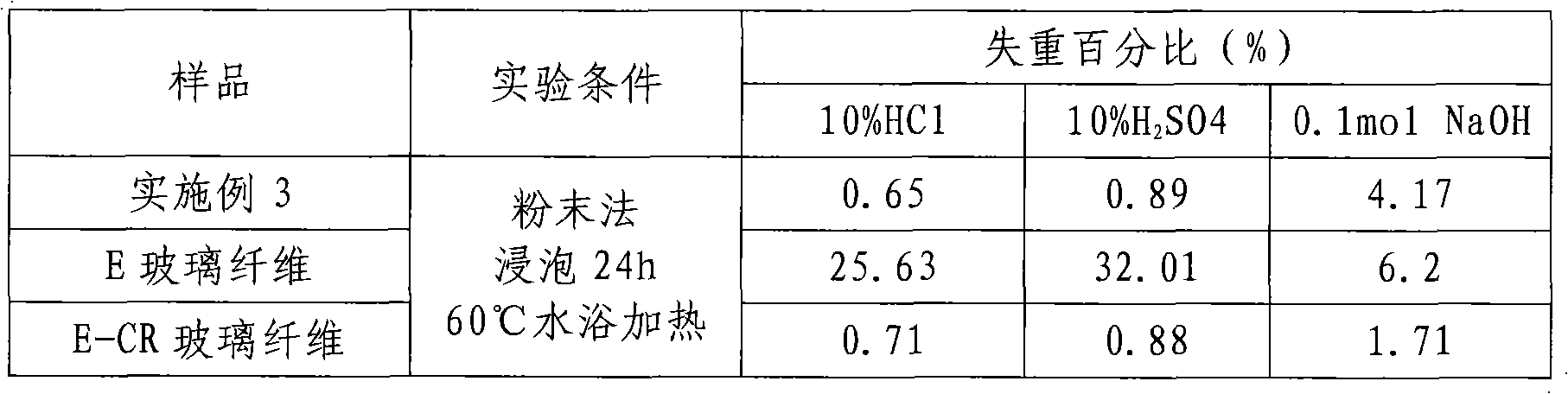

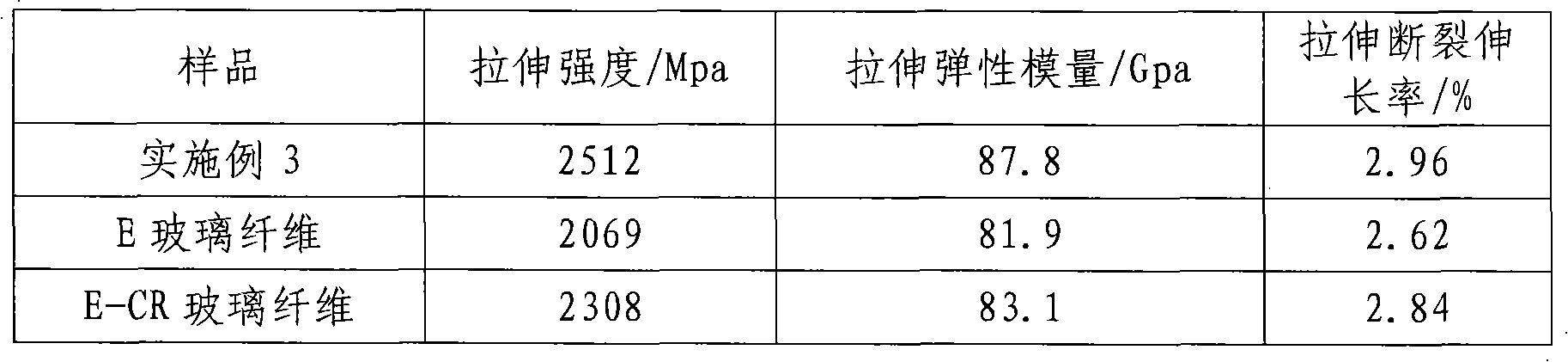

Effect test

Embodiment Construction

[0086] The technical solutions of the present invention are further described below through specific examples, and these examples can illustrate but not limit the technical subject of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an organic or inorganic fiberglass for enhancement, and a composition thereof. The fiberglass is characterized in that the fiberglass comprises the following components, by weight, 56-61 parts of SiO2, 12-16 parts of Al2O3, 18-22 parts of CaO, 3.5-6 parts of MgO, 23-27 parts of CaO+MgO, 0.2-0.5 parts of TiO2, 0.8 or less of Na2O+K2O, and 0.5 or less of Fe2O3. Boron or fluorine contained raw materials are not specially added to glass fiber products of the invention, so the cost is saved, and the discharge of harmful exhaust gases is substantially reduced; the tensile strength, the elastic modulus, the corrosion resistance and the high temperature resistance of the products are substantially higher than that of traditional E glass fibers, so the products can be applied to fields of automobiles, wind blades, compressed gas cylinders and the like; and the products which have good fiber forming properties allows the large scale production to be economically realized.

Description

Technical field: [0001] The invention relates to a glass fiber, in particular to a boron-free and fluorine-free reinforcing glass fiber composition, which belongs to the technical field of glass fiber materials. Background technique: [0002] Glass fiber belongs to inorganic non-metallic materials. It has many advantages such as good insulation, strong heat resistance, good corrosion resistance and high mechanical strength. It is currently the most widely used type of matrix material in reinforced composite materials. [0003] The glass component used to make continuous glass fibers is currently mainly E glass, which accounts for almost 99% of the total glass fiber production. Traditional E-glass fiber belongs to SiO 2 -Al 2 o 3 -B 2 o 3 -CaO system glass, this kind of glass has good electrical and mechanical properties, and has relatively low molding temperature and wide operating temperature range, and good processing performance, so it has become the most widely used...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C13/02

CPCC03C3/087C03C13/00

Inventor 韩利雄姚远

Owner CHONGQING POLYCOMP INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com