Corona-resistant polyimide film and process for preparing same

A technology of polyimide film and corona resistance, which is applied in the field of preparing nano-polymer insulating materials, can solve the problems of limited dispersion, low peel strength, and difficulty in meeting processing requirements, and achieve outstanding dispersion effect, excellent comprehensive performance, The effect of the preparation method is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] 1. Preparation of component A: Pre-disperse the raw materials of component A by stirring, and then use high-pressure dispersion technology to restore the nano-filler to the original nano-particle size after dispersion, so that the resin can be homogeneous after dispersion, and the resin can be uniformly distributed through the resin Wrapped on the surface of the nano-filler and cross-linked to prevent the re-agglomeration of the nanoparticles, so that the nano-filler and resin system in the A component become a uniform and stable corona-resistant component A;

[0023] 2. Preparation of component B: react two or three kinds of reactive monomers in a polar solvent, and control its molecular weight by controlling the viscosity to prepare component B of low-molecular polyamic acid solution;

[0024] 3. Preparation of corona-resistant polymer polyamic acid solution: put component A into component B, stir the nanometer filler in the mixing system uniformly and stably through s...

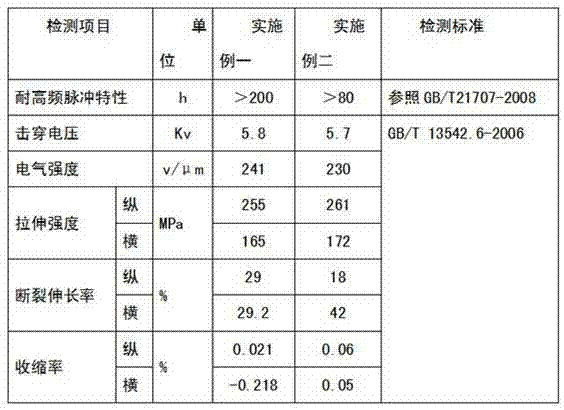

Embodiment 1

[0037]1. Component A of corona-resistant slurry: mix nano-alumina with N,N-dimethylacetamide

[0038] and silane coupling agent in the container by stirring for high-speed shear pre-dispersion, put into self-made

[0039] The resin is pre-dispersed, and then dispersed in a high-pressure disperser to make a uniform and stable corona-resistant slurry. The amount of silane coupling agent is 0.03~0.5% of the solvent amount, preferably 0.03~0.08%,

[0040] The amount of nano-alumina is 10-35% of the solid content in the polyamic acid solution, preferably 16-28%, and the amount of resin and nano-alumina is 1:1.

[0041] 2. Component B of low-molecular polyamic acid solution: at room temperature and normal pressure, put 4,4'-diaminodiphenyl ether into the polar solvent N,N-dimethylacetamide in the reaction kettle, and accelerate the process by stirring. Dissolve, then sprinkle pyromellitic dianhydride into the system for reaction, use cooling water to control the reaction temperatur...

Embodiment 2

[0048] 1. Component A of the corona-resistant slurry is the same as that in Example 1.

[0049] 2. Low-molecular polyamic acid solution component B, at room temperature and normal pressure, put 4,4'-diaminodiphenyl ether and p-phenylenediamine into the reaction kettle polar solvent N,N-dimethylacetamide In the process, the dissolution is accelerated by stirring, and then the pyromellitic dianhydride is scattered into the system for reaction, and the reaction temperature is controlled by cooling water to ≤65°C, and the low-molecular polyamic acid solution is prepared through the reaction, and the viscosity is low. The reaction molar ratio of tetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether to p-phenylenediamine is ≤0.8:0.7:0.3

[0050] 3. The preparation of the corona-resistant polymer polyamide solution is the same as that in Example 1. Among them, the final reaction mol ratio of pyromellitic dianhydride to 4,4'-diaminodiphenyl ether and p-phenylenediamine is 1:0.7:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com