340MPa-grade high-strength cold-rolled steel plate used for deep-drawing, and production method thereof

A cold-rolled steel plate, high-strength technology, applied in the field of metal materials, can solve the problems of high Si content, high cost, and increased number of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

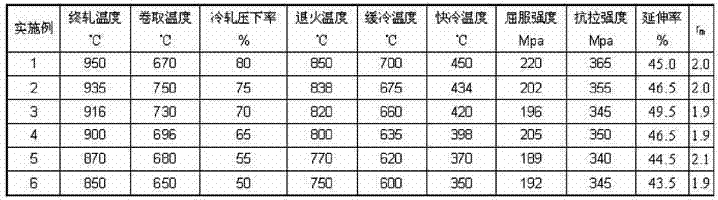

[0032] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

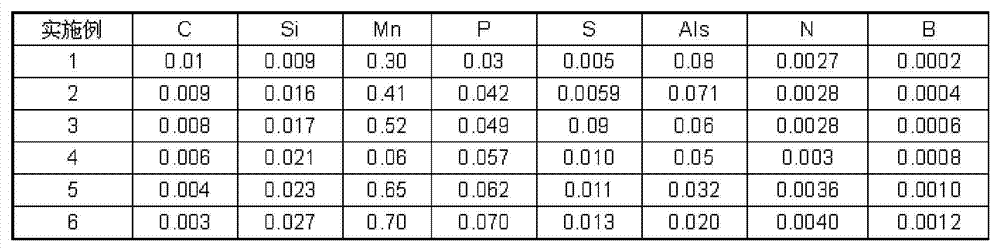

[0033] The weight percent of the main chemical components for manufacturing the cold-rolled steel sheet is: C: ≤0.010%; Si: ≤0.060%; Mn: 0.30%-0.70%; P: 0.030%-0.070%; S: ≤0.015%; Als: 0.020 %~0.080%; N: ≤0.0050%; B: 0.0002%~0.0012%.

[0034] For realizing the manufacture of steel of the present invention, technological process and technological content are as follows:

[0035] (1) Pretreatment of molten iron: Requires front and rear slag removal.

[0036] (2) Converter smelting: no pig iron is added; slag-retaining operation is strengthened during tapping; lime is added during tapping without deoxidation.

[0037] (3) Alloy fine-tuning station: add small aluminum particles and carry out strong stirring operation to initially reduce the top slag of the ladle.

[0038] (4) RH furnace r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com