Depositing apparatus for forming thin film

A technology of deposition equipment and equipment, which is applied in the direction of ion implantation plating, coating, electrical components, etc., can solve the problems of production reduction, impact of component and unit performance, shutdown, etc., and achieve the effect of stable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an exemplary embodiment of a deposition apparatus for forming a thin film according to the present invention will be described with reference to the accompanying drawings.

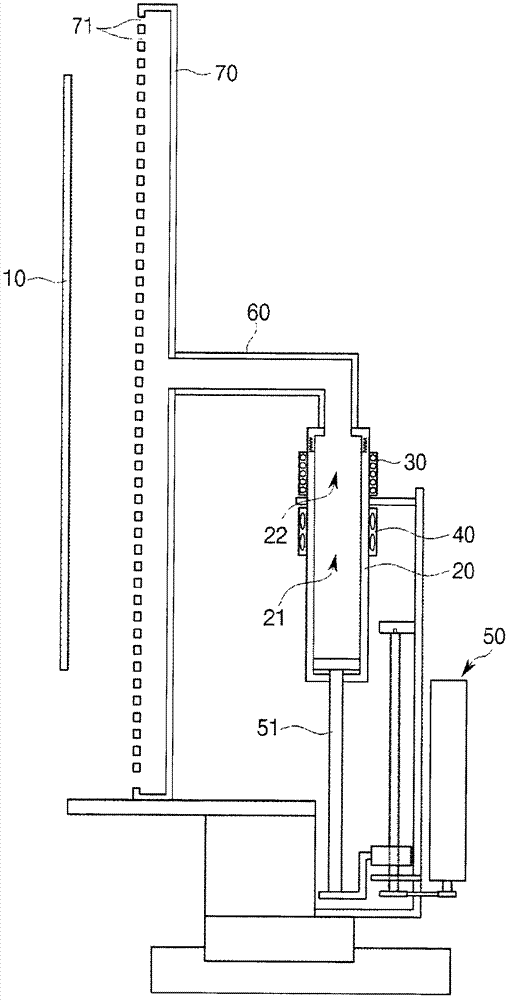

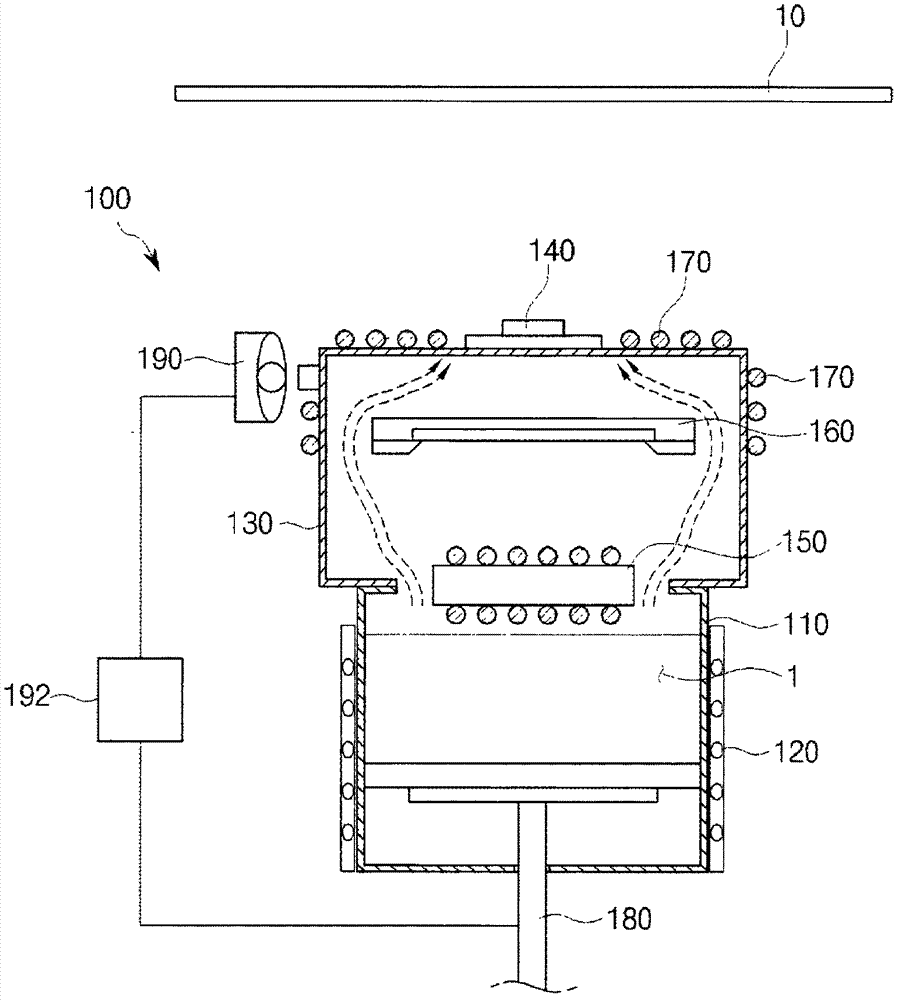

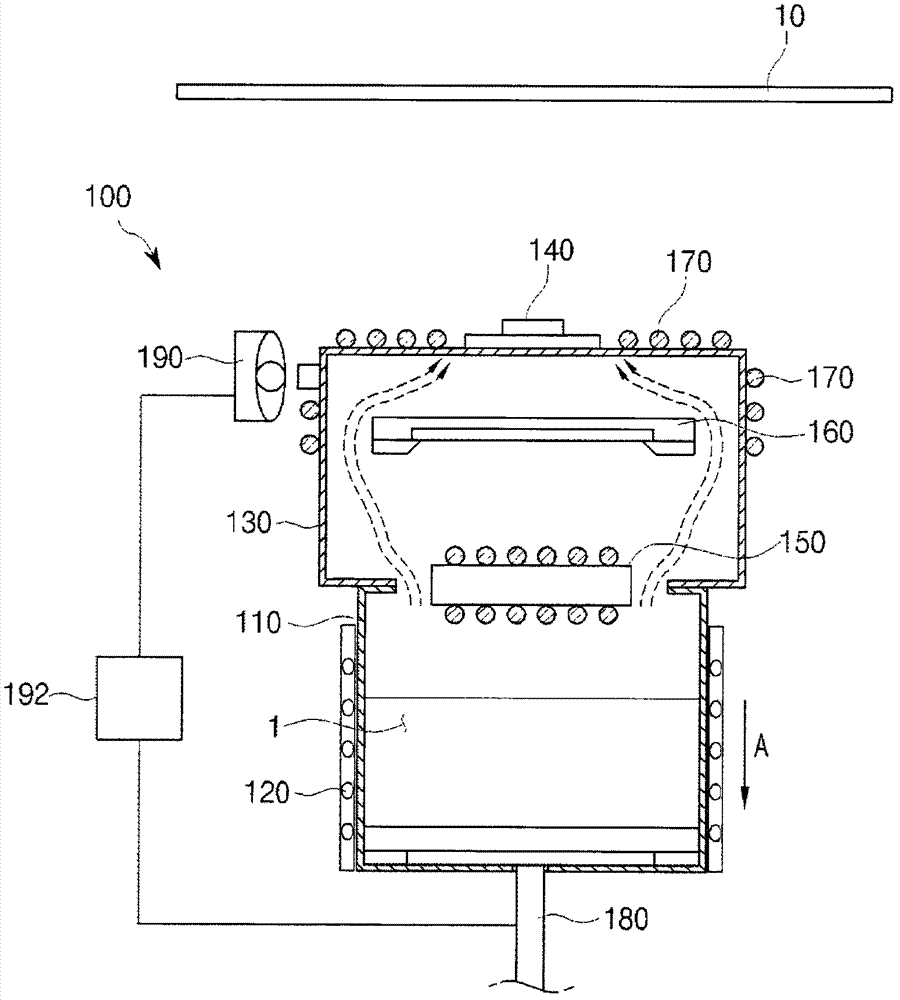

[0032] figure 2 is a schematic diagram of a deposition apparatus for forming a thin film according to an exemplary embodiment, image 3 To show a view of conveying the source material in a direction away from the first heater at figure 2 in deposition equipment used to form thin films.

[0033] see figure 2 and image 3 , the deposition apparatus for forming a thin film in this exemplary embodiment includes a source container 110, a cooler 120, an evaporation chamber 130, an orifice 140, a first heater 150, a blocking plate 160, a second heater 170, a transfer unit 180. A sensor 190 and a controller 192. The deposition device is a device capable of evaporating organic substances and depositing the organic substances on the substrate in the form of a thin film.

[0034] The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com