Hanging bracket for quick construction on inner wall of spherical tank

A spherical tank and fast technology, which is applied to the scaffolding of house structure support, house structure support, house structure support, etc., can solve the problems that the equipment cannot stand and unfold effectively, waste of manpower, material resources, and low labor efficiency, so as to reduce construction Effects of cost and quantity of materials, improvement of construction efficiency, and shortening of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

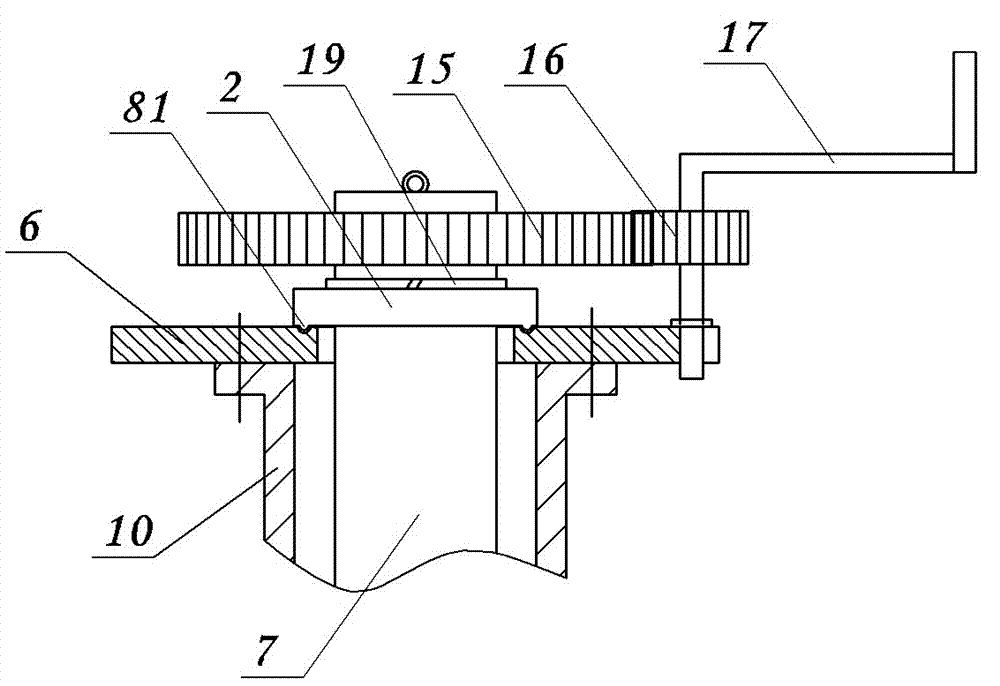

[0027] There are various forms of the rotating mechanism, and the rotating mechanism of the present embodiment can be found in figure 2 , including a central rotating shaft 7, on which a flange plate 6 fixedly installed with the central manhole is set, and a limit plate 2 is also set on the central rotating shaft 7, and the limit plate 2 is located on the side of the flange plate 6 upper side. The limit plate 2 and the central shaft are fixed by a circlip 19, and a contact surface matching mechanism 8 is arranged between the limit plate 2 and the flange 6, that is, the lower surface of the limit plate 2 and the upper surface of the flange 6 A ring-shaped convex-concave matching structure 81 is adopted on the contact surface of the surface.

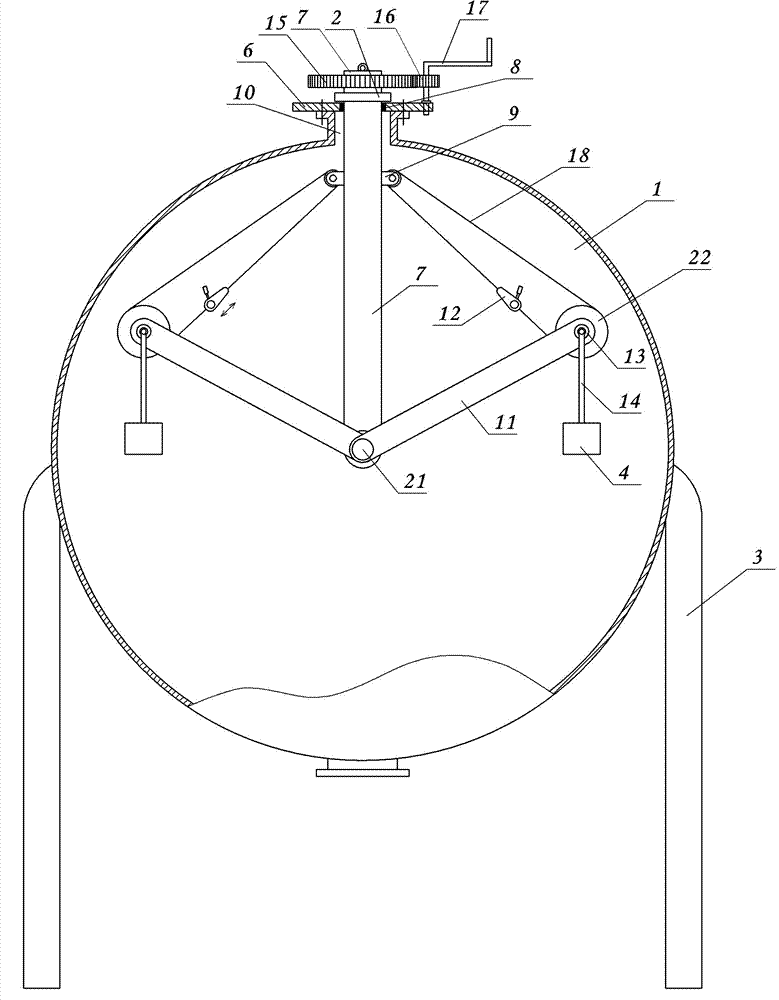

[0028] The upper part of the central rotating shaft 7 (located inside the sphere) is provided with hinged ears 9, and the lower end is provided with a supporting rotating shaft 21, which is located at the center of the sphere, and two or...

Embodiment 2

[0033] Embodiment 3: The drawings are not drawn, and the content is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is: the rocker is replaced with a controllable small motor.

Embodiment 3

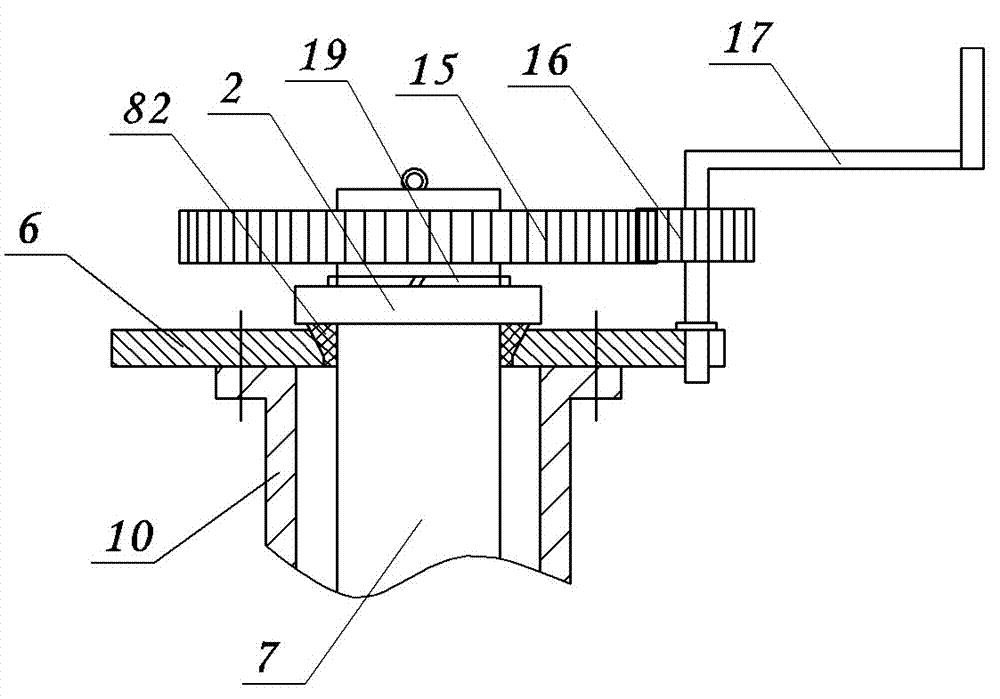

[0034] Embodiment four: see figure 1 , image 3 , Figure 4 and Figure 7 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the central hole of the flange 6 adopts an inverted tapered structure, and a tapered wear-resistant pad 82 is set in the inverted tapered hole. Shape wear-resistant pad 82 upper ends contact with the limit disk lower surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com