Oil cooling motor

An engine and oil cooling technology, which is applied in the cooling of engine components, machines/engines, engines, etc., can solve the problems of heating, spark plug hole cooling can not be improved, etc., to achieve heat suppression, cooling performance improvement, and improve cooling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

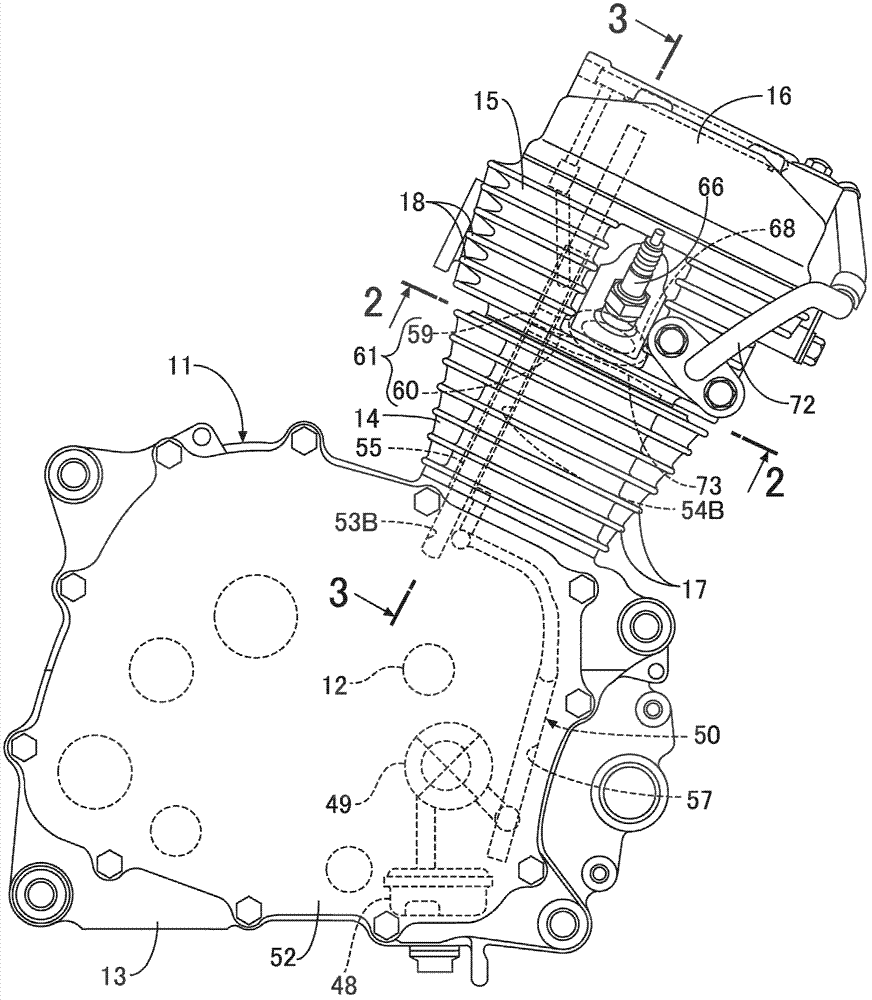

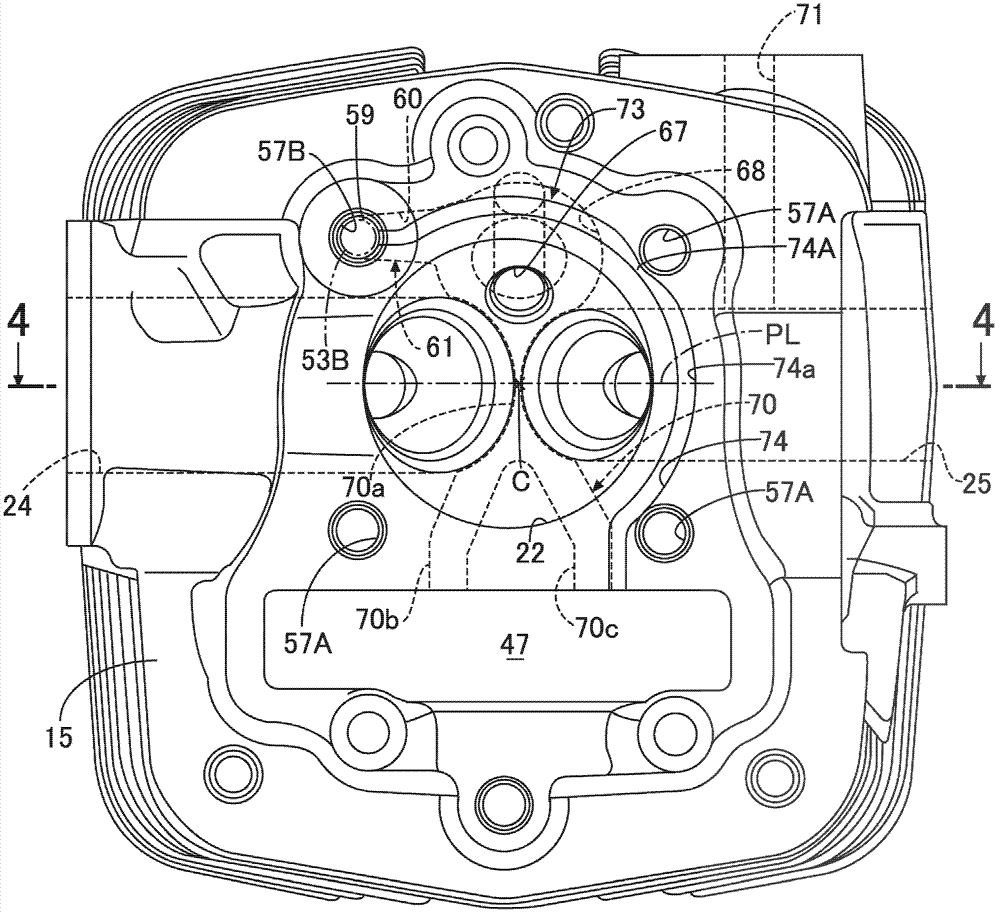

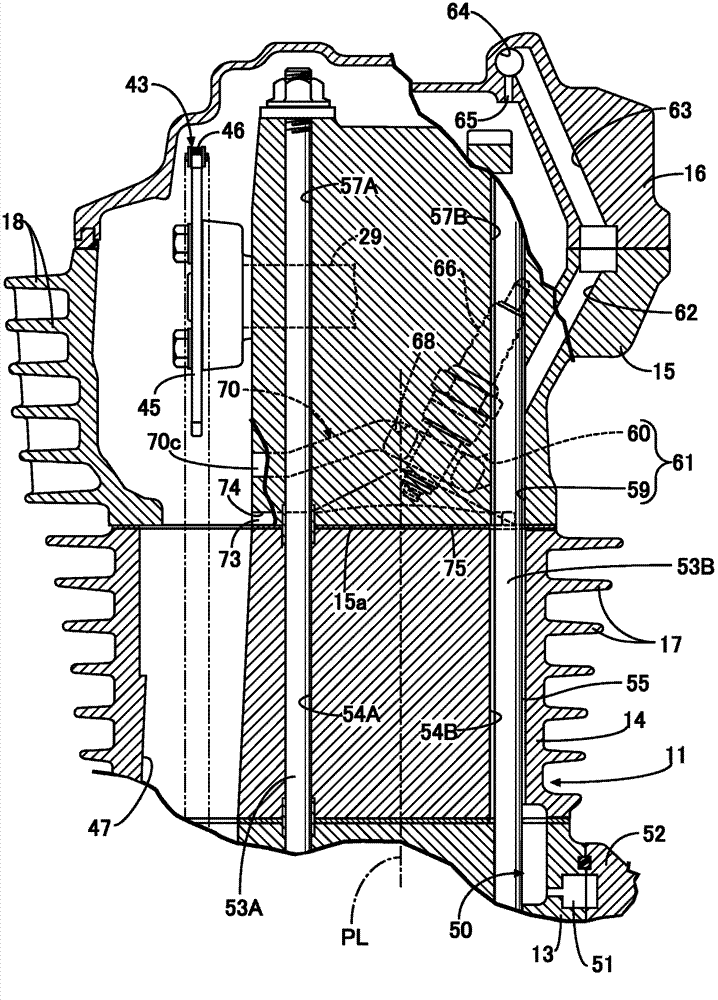

[0088] Embodiments of the present invention will be described with reference to the drawings.

[0089] refer to Figure 1 to Figure 6 , to describe the first embodiment of the present invention, first, in figure 1 Among them, for example, the engine main body 11 of an oil-cooled engine mounted on a motorcycle includes a crankcase 13 that supports the crankshaft 12 in a rotatable manner. 13, the cylinder block 14 combined with the cylinder block 14, the cylinder head cover 16 combined with the cylinder head 15, and the outer surfaces of the cylinder block 14 and the cylinder head 15 are protrudingly provided with along A plurality of cooling fins 17 , 17 . . . ; 18 , 18 . . . arranged at intervals in the vertical direction.

[0090] together with reference Figure 2 to Figure 5 A slidable piston 20 is fitted into the cylinder tube 19 provided in the cylinder block 14 , and the piston 20 is connected to the crankshaft 12 via a connecting rod 21 . Between the cylinder block 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com