Gas engine set

A gas and unit technology, which is applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of shortening service life, shortening battery life, and reducing service life, so as to prolong service life, increase service life, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

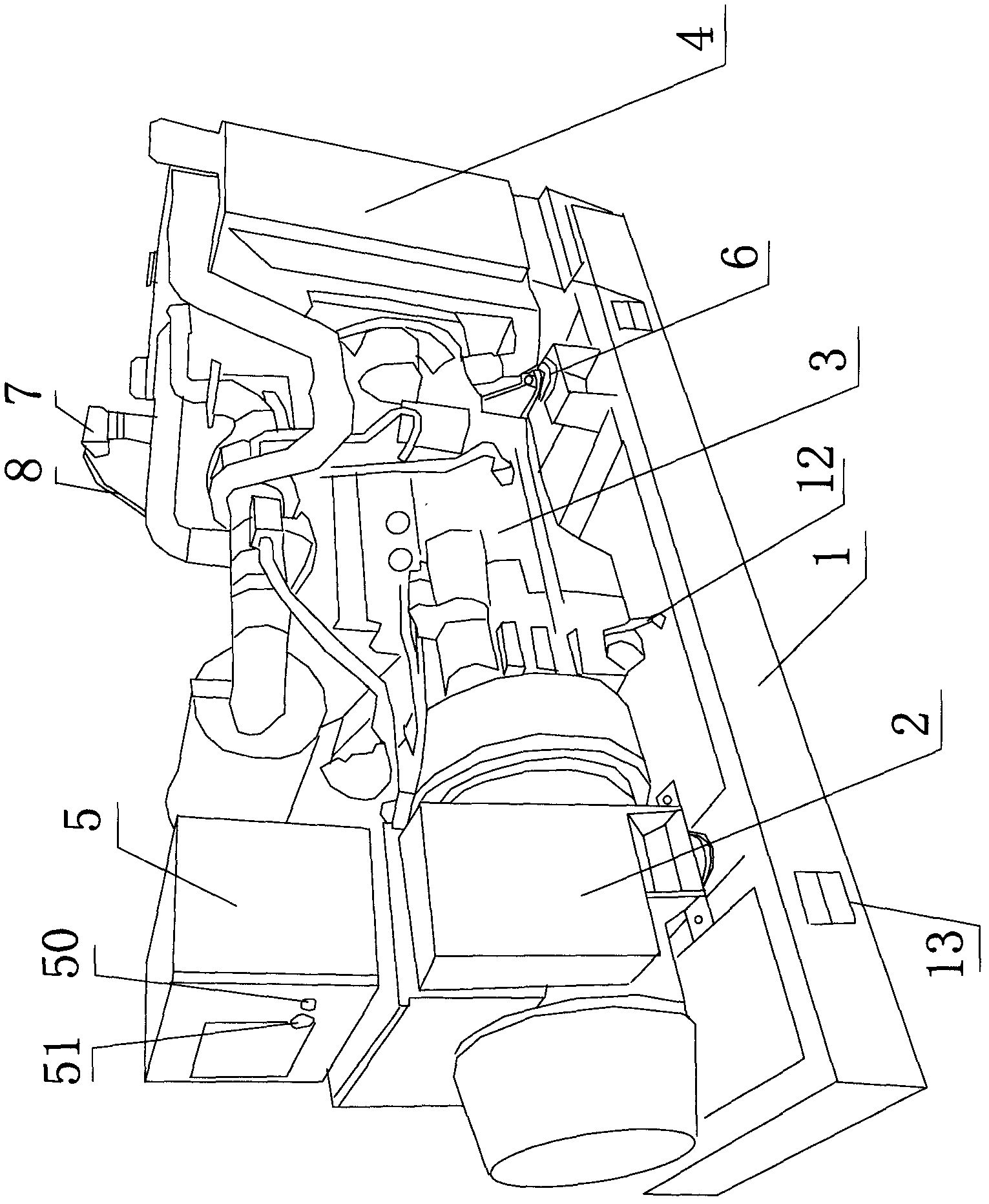

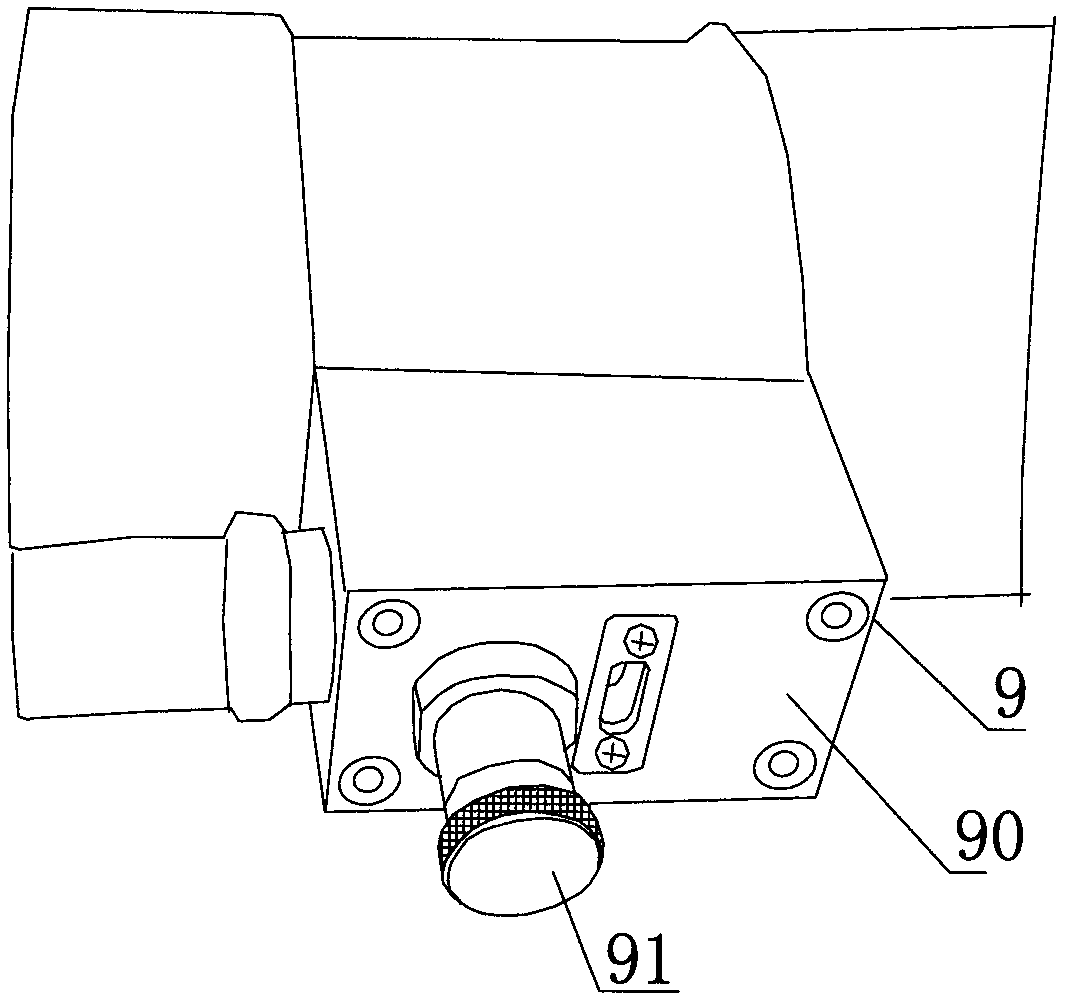

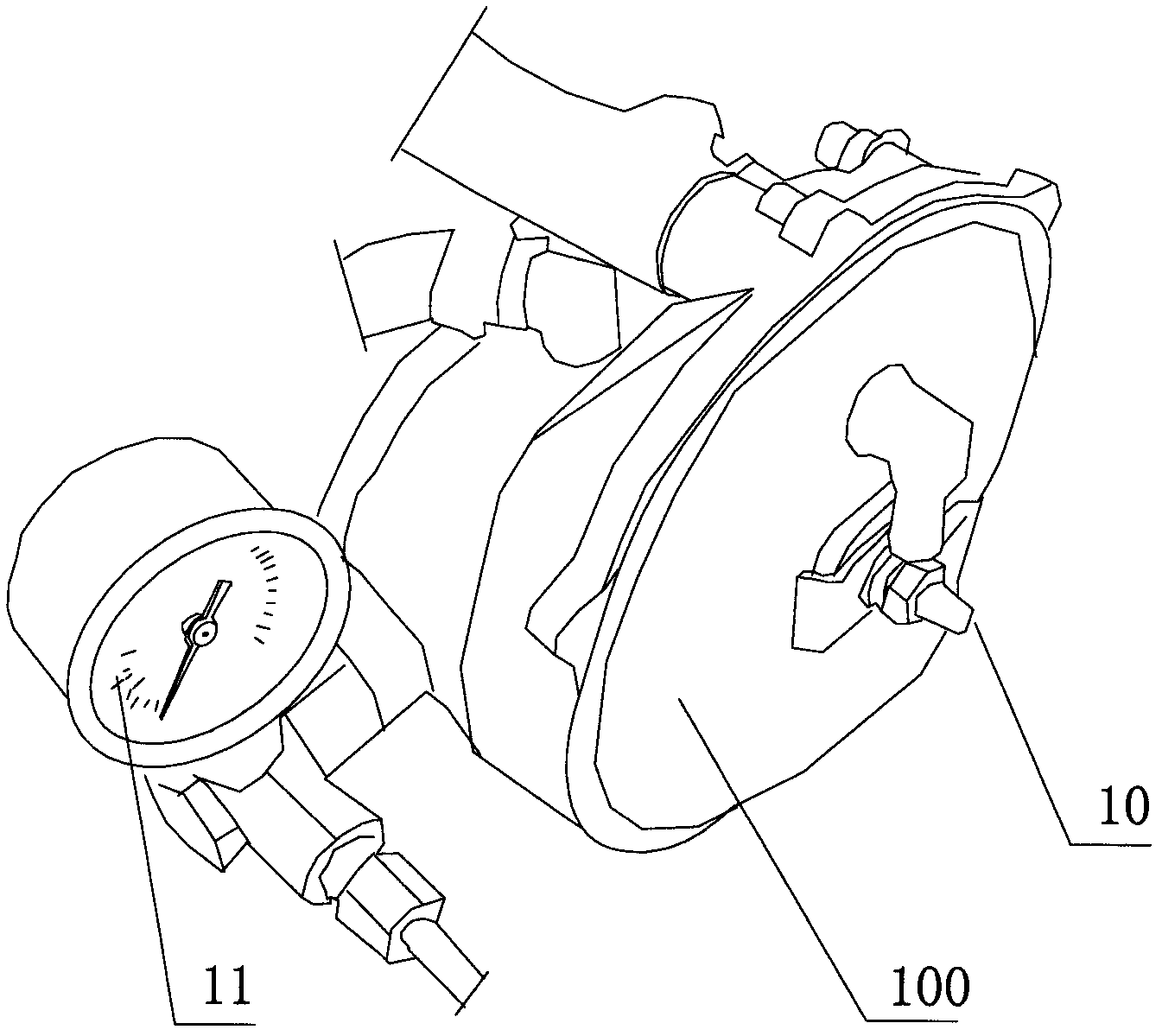

[0017] In this embodiment, refer to Figure 1 to Figure 5 , The gas unit includes a frame 1, and a generator 2, an engine 3, and an electric box 4 arranged on the frame 1. An operation controller 5 for manual operation is arranged above the generator 2, as well as switches and Gas controller (not shown); the engine 3 is provided with an intake pipe, a stop valve, a filter, a pressure test gauge, a vaporizer, an actuator, a limit valve, a mixer, a supercharger, and a middle Cooler, integrator, high-voltage package, explosion-proof device and smoke exhaust pipe (all not shown); said frame 1 is provided with anti-vibration device 6; said high-voltage package and engine 3 are connected with lightning protection wire; The explosion-proof device 7 is a remote explosion-proof device, including an explosion-proof device body, and a gas pipe 8 with one end connected to the explosion-proof device body and the other end connected to the cylinder; the mixer 9 includes a mixer body 90 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com