Method for detecting sealing property of sealed container based on standard pressure vibration curve

A technology of sealing performance and standard pressure, which is applied in the direction of using liquid/vacuum to measure liquid tightness and measuring the rate of increase and deceleration of fluid, etc., can solve the problems that the detection of furnace cavity sealing performance cannot be automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

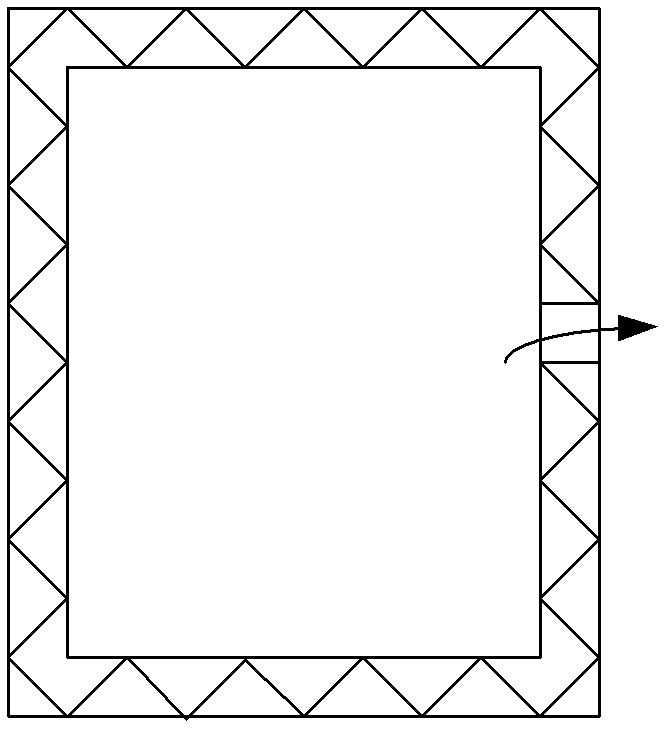

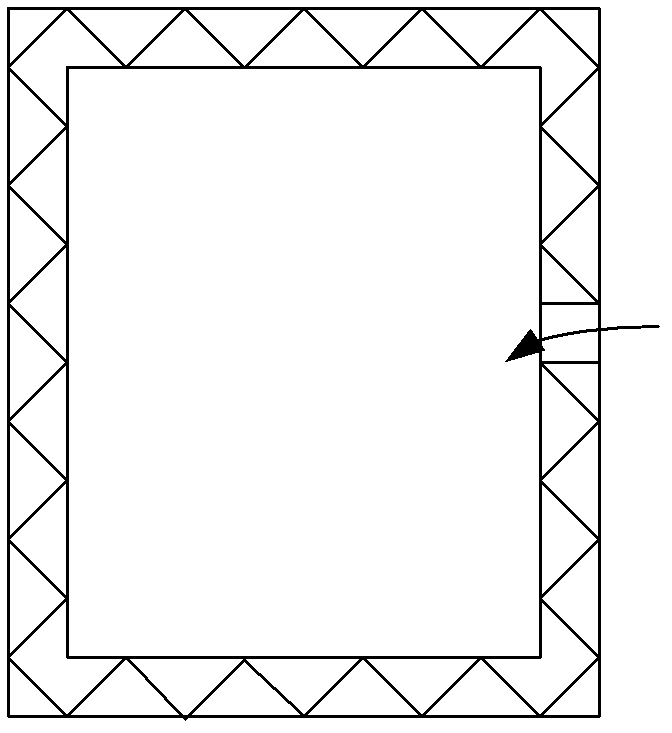

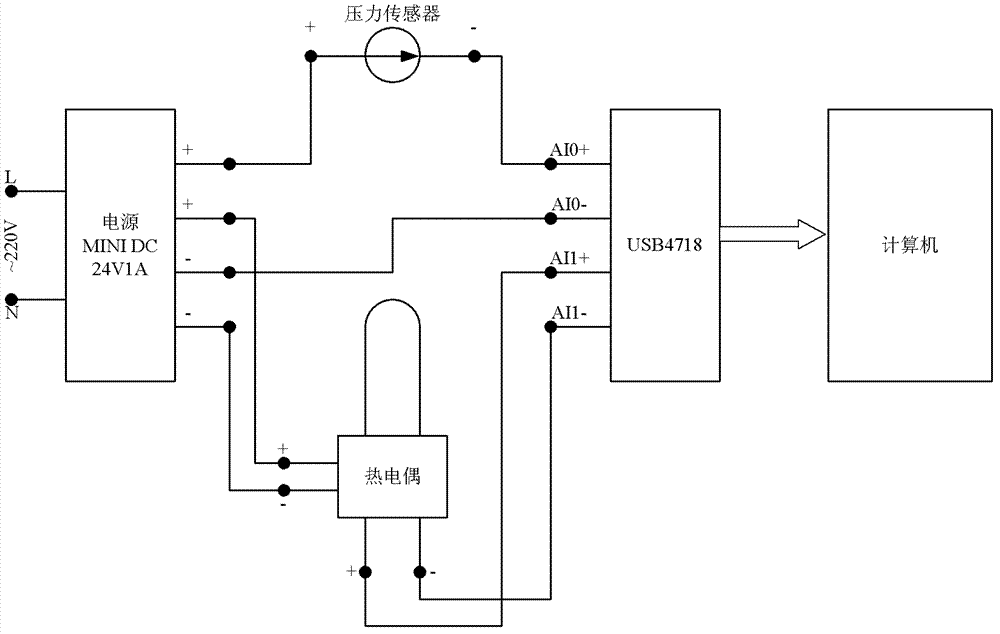

[0102] The present invention is implemented in the air tightness detection of the RCS furnace chamber of a continuous annealing unit. After the furnace chamber sealing work is completed, the furnace chamber is first charged or depressurized to a certain pressure, and then the pressurization or depressurization is stopped. There is inevitably leakage in the furnace chamber, and the pressure in the furnace chamber changes gradually. When the pressure in the furnace chamber changes to a certain pressure (400daPa for positive pressure test, -270daPa for negative pressure test), the air tightness test will start. This time will be taken as the zero time point. Every certain time (take 30 seconds), record the pressure, when it reaches a certain time (take 6 hours), write down the pressure at that moment and end the pressure recording, thus get a pressure change curve, compare the pressure curve with the standard Compared with the pressure curve of the furnace chamber, it can be judge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com