Method for measuring sight line stabilizing accuracy of photoelectric sight-stabilizing system

A photoelectric stable pointing and stable precision technology, applied in the field of optical measurement, can solve the problems of high cost, error, guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred examples.

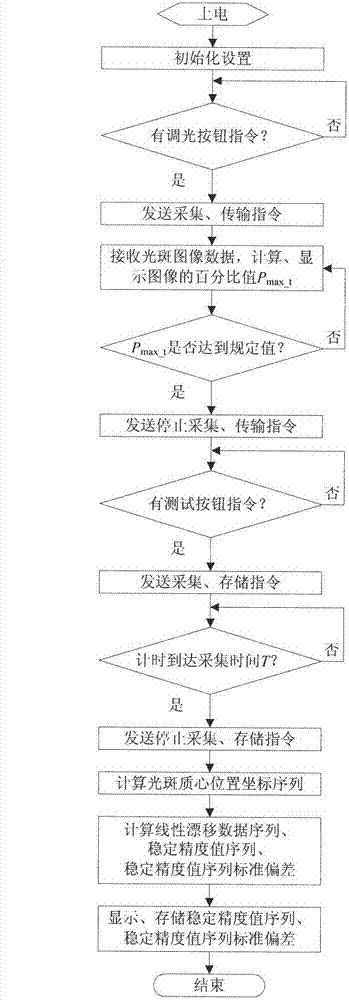

[0061] The concrete implementation process of the present invention comprises the following operation steps:

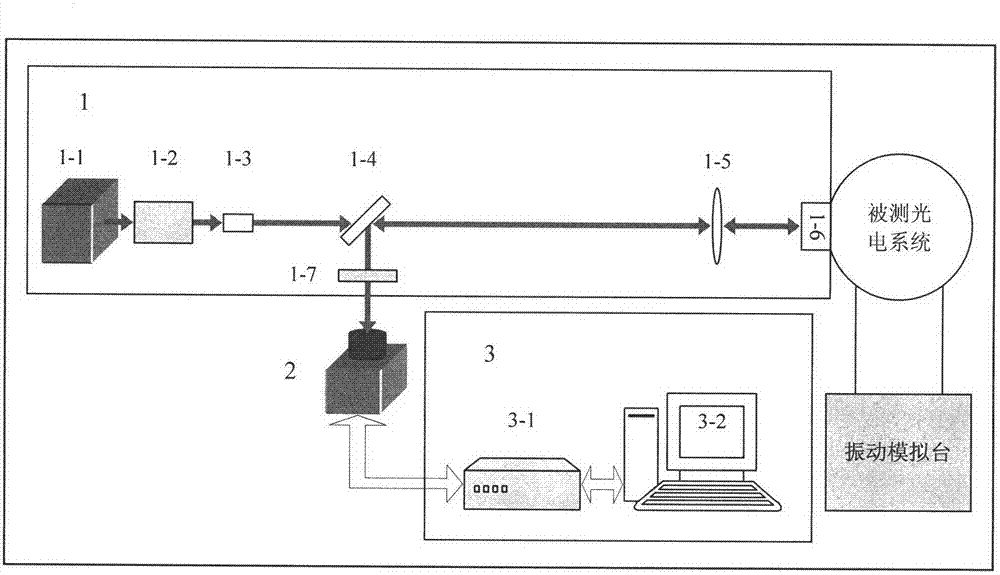

[0062] The first step is to install the object under test

[0063] Such as figure 1 As shown in Fig. 1, the electro-optical stabilization system under test is fixed on the vibration simulation table with steel bolts and clamps. Turn on the vibration simulation table, set the vibration mode of the simulation table to fixed frequency mode, and set the working state to vibration stop state. In this embodiment, the vibration simulation platform is a large-scale vibration simulation experiment device from UD Company of the United States, and its vibration sweep frequency range is 2 Hz to 500 Hz.

[0064] The second step is to build the measuring device

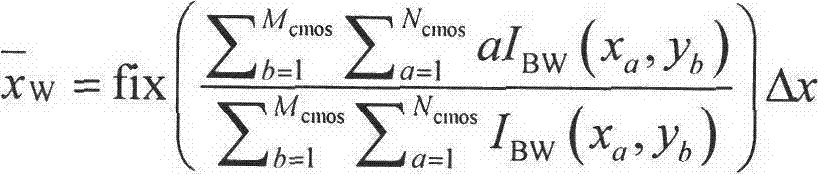

[0065] The method for measuring line-of-sight stability accuracy of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com